Excertos do catálogo

XI'AN SHELOK INSTRUMENT COMPANY LIMITED 1.Pressure Transmi�er 4.Dead Weight Tester 7.Temperature Transmi�er 2.Pressure Gauge 5. Level Transmi�er 8.Density Meter

Abrir o catálogo na página 1

Liquid Turbine Flow Meter User Manual ' Warning When the flow meter is installed at explosion hazard field, DON'T remove the COVERPLATE when the meter is powered. Please make parameter settng at safe filed prior to installation. > Special Notices Pictures & Descriptions are for your information only, please refer to the actual product. Parameters are subjected to changes without notice. GENERAL INFORMATION This manual will assist you in installing, using and maintaining your turbine flow meter. It is your responsibility to make that all operators have access to adequate instructions about...

Abrir o catálogo na página 2

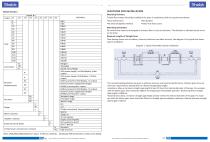

Shelok SPECIFICATIONSPerformance Measurable Flow Rate Range and Pres Level: (See table 1) Table 1. Measurable Flow Rage Range and Pressure Rating Standard - 304 Stainless Steel Optional - 316 Stainless Steel Tungsten Carbide Standard - 2Cr13 Stainless Steel (Optional Alloy CD4Mcu) 316 Stainless Steel Power Supply: Sensor: Transmitter: Field Display Type B: Field Display Type C: Accuracy: Standard: ±1% of reading; Housing: Bearings and Shaft: Rotor: Retaining Rings: Output Signal: (Where applicable) Sensor: Pulse signal (Low Level: <0.8V; High Level: >8V) Transmitter: 4 to 20 mA DC current...

Abrir o catálogo na página 3

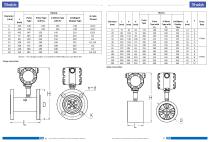

CAUTIONS FOR INSTALLATION Mounting Positions Turbine flow meters should be installed at the place in compliance with the requirements below: •Easy maintenance •No vibration •No electromagnetic interface •Away from heat source Mounting Orientation All turbine flow meters are designed to measure flow in only one direction. The direction is indicated by the arrow on the body. Required Lengths of Straight Runs Flow altering device such as elbows, valves and reducers can affect accuracy. See diagram 1 for typical flow meter system installation. Diagram 1. Typical Flow Meter System Installation...

Abrir o catálogo na página 4

See diagram 2 for straight pipe length requirement when there is altering device. Diagram 2. Number of Pipe Diameter (D=Diameter) Warning:Precaution for direct sunshine and rain when the meter is installed outside. Cavitation can be caused by entrained air, and it can seriously damage the rotor on a turbine flow meter. An amount higher than about 100 mg/l of entrained air or gas can produce error. In addition, cavitations can be caused by too little back pres on the flow meter. For turbine flow meters, you should provide a back pres (downstream pres) of at least 1.25 times the vapor pres,...

Abrir o catálogo na página 5

Notice: The straight section is included for DN4-DN10, but not DN15-DN Flange connection Wafer Connection

Abrir o catálogo na página 6

Sanitary Connection

Abrir o catálogo na página 7

Main Power Description of the symbols: + Default Function O Optional • 2. Pulse with Explosion Proof: Notice: l.The pulse means the signal which is in direct proportion to the impeller speed. 2.The scaled Pulse means the signal when the flow rate reach ONE unit volume( m3, L, 0.01L...) 3.The batter model is ER34615 4.The battery model is ER26500 Notice: (1) High level amplitude >22V (2)Low level amplitude<0.8V (3)Load capacity>1100Q (4)Pulse frequency<3000Hz •3. 4-20mA Output with Explosion Proof Type Notice: Load resistor is <

Abrir o catálogo na página 8

Pulse / Scaled Pulse output

Abrir o catálogo na página 9

Pulse / Scaled Pulse output

Abrir o catálogo na página 10

Parameter set There are four keys: "Enter", "^", "t", "Esc". Description of Password Grade

Abrir o catálogo na página 11

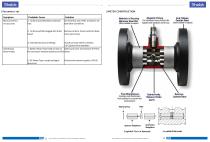

Parameter set METER CONSTRUCTION Symptom Measurement is not accurate Probable Cause Solution 1. Turbine operated below minimum rate. Increase flow rate. Refer to Section 3.0 Operation Conditions Materials of Housing Stainless Steel 304 • Others available on request) Magnetic Pickup End Fittings: For hazardous areas, pickup colls supplied with explosion proof boss. Carbide Steel (Others available on request) 2. Turbine partially clogged with dried liquid Remove turbine. Clean carefully. Make rotor spins freely. 3. Installed too close to fiffings. Install correctly. Refer to Section 5.0...

Abrir o catálogo na página 12

METER CONSTRUCTION Hereby provides a limited warranty against defects in materials and workmanship. This product includes a one-year warranty. The warranty period shall begin on the date of the original new equipment purchase. Warrantor's obligation hereunder shall be limited to repairing defective workmanship or replacing or repairing any defective parts. In the event Purchaser believes the product is defective, the product must be returned to, transportation prepaid by Purchaser, within the appropriate warranty period relative to the product. If 's inspection determines the workmanship or...

Abrir o catálogo na página 13Todos os catálogos e folhetos técnicos Xi'an Yunyi Instrument Co.

-

K series

3 Páginas

-

YX-2006B

2 Páginas

-

XY-2002

1 Páginas

-

YFM4800E

14 Páginas

-

YD32

2 Páginas

-

Relative pressure transmitter YD38

3 Páginas

-

Temperature calibrator WT

2 Páginas

-

Bimetallic thermometer WSS series

2 Páginas

-

Pt100 temperature sensor

3 Páginas

-

Thermistor temperature sensor

2 Páginas

-

Pt100 temperature transmitter

3 Páginas

-

Digital density meter JL-T

6 Páginas

-

Process density sensor

8 Páginas

-

Digital density meter YMF883

4 Páginas

-

Digital density meter JL-YT

4 Páginas

-

Digital density meter JL-LD

2 Páginas

-

Digital density meter JL-SD

2 Páginas

-

Digital density meter JL-GD

2 Páginas

-

Portable pH meter K series

2 Páginas

-

Digital density meter YMF-886

5 Páginas

-

Leak calibrator XY-2006B

2 Páginas

-

Deadweight tester JY

2 Páginas

-

Pressure calibrator XY-2001A

2 Páginas

-

Pressure calibrator YX-60

2 Páginas

-

Leak calibrator YX-2001C

2 Páginas

-

Absolute pressure gauge YK-100

2 Páginas

-

Dial pressure gauge YK-M3 series

3 Páginas

-

Dial pressure gauge YK-M4

2 Páginas

-

Differential pressure gauge YK-M2

3 Páginas

-

Absolute pressure gauge YK-120B

2 Páginas

-

Absolute pressure gauge YK-80

2 Páginas

-

Absolute pressure gauge YK-100B

2 Páginas

-

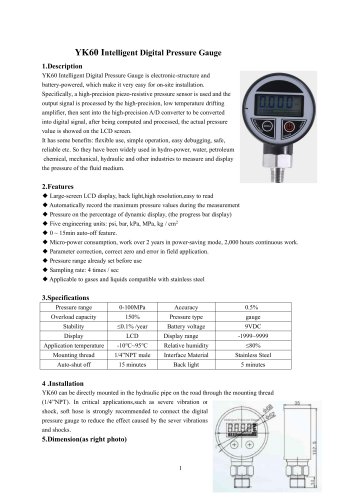

Pressure gauge with LCD display YK60

2 Páginas

-

Infrared flow meter YFM-4800

21 Páginas

-

Electromagnetic flow meter YFM3800

3 Páginas

-

Mass flow meter YFU2000-B

4 Páginas

-

Ultrasonic flow meter TUF-2000H

4 Páginas

-

Ultrasonic flow meter HK-G4-G6-G10

8 Páginas

-

Mass flow meter Coriolis

14 Páginas

-

Orifice flow meter

6 Páginas

-

Mass flow meter MF4000

3 Páginas

-

Mass flow meter

3 Páginas

-

Ultrasonic flow meter YFU2000-B

4 Páginas

-

Vortex flow meter YFV

20 Páginas

-

Ultrasonic flow meter YFU2000H

14 Páginas

-

Mass flow meter YFV300

20 Páginas

-

Mass flow meter YFT300D

13 Páginas

-

Turbine flow meter

13 Páginas

-

Mass flow meter MF5700

3 Páginas

-

Radar level transmitter YUNYI-806A3

14 Páginas

-

Ultrasonic level transmitter MH-A

11 Páginas

-

Liquids level gauge UHZ-10

1 Páginas

-

Radar level transmitter YUNYI-806A4

14 Páginas

-

Level measuring instrument

11 Páginas

-

Liquids level gauge YLR68

12 Páginas

-

Liquids level gauge YR80G series

5 Páginas

-

Liquids level gauge

3 Páginas

-

Piezoresistive level sensor YLT325

4 Páginas

-

Radar level sensor

12 Páginas

-

Piezoresistive level transmitter

4 Páginas

-

Absolute pressure transmitter YD32-S

4 Páginas

-

Relative pressure transmitter YD33

4 Páginas

-

Absolute pressure transmitter YD34

4 Páginas

-

Absolute pressure transmitter YD37

4 Páginas

-

Diaphragm pressure switch

2 Páginas

-

Digital pressure controller

2 Páginas

-

Absolute pressure transmitter YD-323

2 Páginas

-

Relative pressure transmitter

2 Páginas

-

Explosion-proof pressure transmitter

2 Páginas

-

YD31 series

4 Páginas