Excertos do catálogo

Welding Alloys Group Cladding - Weld overlay - Surfacing

Abrir o catálogo na página 1

This catalogue presents a selection of standard products for hardfacing, cladding and thermal arc spraying applications. Welding Alloys cored wires for joining applications feature in a separate catalogue. We will gladly examine any special request. Please do not hesitate to consult us. Our technical ‘spark’ solves your industrial challenges Contents Since its foundation in 1966, the Welding Alloys Group, an independent group, has specialised Introduction 2 in the manufacture of cored welding wires for joining, cladding and hardfacing applications - Definitions and using this...

Abrir o catálogo na página 2

Which Process? O f ^ Co Size and shape of work piece Surface finish required? Base material - chemical to be hardfaced? As welded, machined, polished composition? Operational difficulties? Working environment? Welding in a workshop On site Available welding equipment? Deposit thickness - number of layers? Technical objectives? Performance Reliability Service lifetime _t t_ Working conditions? Abrasion Impact Thermal fatigue Corrosion Cored wires Hardfacing by arc welding is a surfacing operation to extend the service life of industrial components, preemptively on new components,...

Abrir o catálogo na página 3

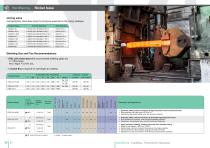

Hardfacing - Work-hardening manganese alloys Shielding Gas and Flux Recommendations - HARDFACE (a cored wire with a seam) the recommended shielding gas is M21: Argon + 15-25% CO2 - ROBODUR / ROBOTOOL (a seamless cored wire) the recommended shielding gases are M12: Argon + 0.5-5% CO2 M13: Argon + 0.5-3% O2 M21: Argon + 15-25% CO2 A neutral flux is required for submerged arc welding Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 4

Hardfacing - Low and medium alloys r Product Name HARDFACE - ROBODUR: for a description of shielding gas and flux recommendations - see page 6 Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 5

Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 6

Product Name HARDFACE - ROBODUR: for a description of shielding gas and flux recommendations - see page 6 g Product Name Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 7

* Hardness Matrix HARDFACE - ROBODUR: for a description of shielding gas and flux recommendations - see page 6 d Product Name Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 8

Hardfacing - Ferritic and martensitic stainless steels Shielding Gas and Flux Recommendations - CHROMECORE the recommended shielding gases are M12: Argon + 0.5-5% CO2 M13: Argon + 0.5-3% CO2 M21: Argon + 15-25% CO2 I1: 100% Argon - A neutral flux is required for submerged arc welding Product Name Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 9

Shielding Gas and Flux Recommendation - CORBRONZE the recommended shielding gases are I1: 100% Argon I3: 0.5-95% He Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable 19 Hardfacing - Cladding - Thermal Arc Spraying

Abrir o catálogo na página 10

Hardfacing - Nickel baseJoining wires Complementary nickel base wires for joining are presented in the joining catalogue Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 11

Shielding Gas Recommendation- STELLOY (Cobalt base) the recommended shielding gas is I1: 100% Argon - Specific TIG versions available in diameter 1.2 mm and 1.6 mm- SAW versions available on request r Product Name Suited to thermal arc spraying ♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 12

♦ Suitable ♦ ♦ Highly suitable

Abrir o catálogo na página 13

Alphabetical Index Packaging Metal basket spool Standard net weight: 25 kg External diameter: Internal diameter: Width: Metal basket spool Standard net weight: External diameter: Internal diameter: Width: EN ISO 544 standard: Plastic spool* Plastic reel* Standard net weight: 15 kg Small plastic spool* Standard net weight: 5 kg Small metal basket spool Standard net weight: 5 kg •Manufactured to order at client's request Technical Information Suitable shielding gases (according to the standard EN ISO 14175) are recommended in decreasing order of preference Welding Alloys...

Abrir o catálogo na página 14

Local presence • Welding Alloys Subsidiaries Strategic Trading Partners WA distributors or sales representatives Welding Alloys Group 2018. WA Cored Wire, WA Integra, WA MultiSu/facer, Hardplate, Hardlite, Tuffplate, DRILL-GUARD and 3-DCarb trade and registered marks and logos are the property of the Welding Alloys Group.

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos Welding Alloys Group

-

WA Integra™

3 Páginas

-

Welding Alloys Group

6 Páginas

-

Joining

15 Páginas

-

Electrodes

9 Páginas

-

Drill Guard

3 Páginas