Excertos do catálogo

Engineering Data Pack HD Industrial Duty Pumps Excellence at work. Excellence in life.

Abrir o catálogo na página 1

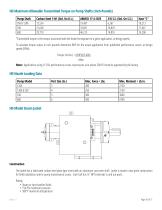

HD Maximum Case, Differential, Discharge, and Suction

Abrir o catálogo na página 2

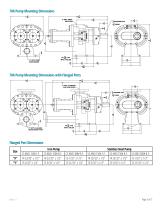

70A Pump Mounting Dimensions 7 2416 70A Pump Mounting Dimensions with Flanged Ports 3 134 3" NPT FLANGED SUCTION PORT 2" NPT FLANGED DISCHARGE PORT Flanged Port Dimensions Size "X" "Y" Iron Pump CS ANSI 150# R.F. 14 23/32" ± 1/2" 15 5/32" ± 1/2"

Abrir o catálogo na página 3

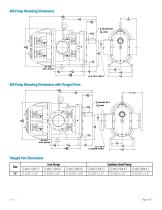

120A Pump Mounting Dimensions 7 2416 120A Pump Mounting Dimensions with Flanged Ports 3 134 4" NPT FLANGED SUCTION PORT 5 8 (4) 13 TYP. 32 MTG. HOLES 3" NPT FLANGED DISCHARGE PORT Flanged Port Dimensions Size "X" "Y" Iron Pump CS ANSI 150# R.F. 13 17/32" ± 1/2" 15 3/8" ± 1/2"

Abrir o catálogo na página 4

330 Pump Mounting Dimensions 2915 32 330 Pump Mounting Dimensions with Flanged Ports 2915 32 "X" 5" NPT FLANGED SUCTION PORT Flanged Port Dimensions Size "X" "Y" Iron Pump CS ANSI 150# R.F. 18 3/32" ± 1/2" 19" ± 1/2"

Abrir o catálogo na página 5

600 Pump Mounting Dimensions 9 3616 600 Pump Mounting Dimensions with Flanged Ports 9 3616 Flanged Port Dimensions Size "X" Iron Pump CS ANSI 150# R.F. 11 5/32" ± 1/2" Stainless Steel Pump SS ANSI 150# F.F. SS ANSI 150# R.F. SS ANSI 300# R.F. 11 5/32" ± 1/2" 11 5/32" ± 1/2" 11 21/32" ± 1/2"

Abrir o catálogo na página 6

Pos. 1 & 2 - Pump 05 = Industrial Duty (ID) Pos. 3 & 4 - Model 16 = Model 70A 31 = Model 120A 75 = Model 330 91 = Model 600 Pos. 5 & 6 - Material of Construction 04 = 316 Stainless Steel 09 = Ductile Iron Pos. 7 - Port 0 = Internal NPT (Std. on ID Models) 3 = Flanged Port Option Pos. 8 - Relief Valve 0 = No Relief Valve Pos. 9 & 10 - Options 01 = Hot Clearance 02 = Special Shaft Material 05 = Special Packing 06 = Special Packing Configuration 08 = Mechanical Seals 09 = Special Bushings 10 = Special Clearances 13 = Steam Jacket/Tracing 19 = Special Ports (ie. Flanged) 21 = Tutriding 26 =...

Abrir o catálogo na página 7

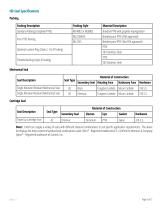

Note: Tuthill can supply a variety of seals with different material combinations to suit specific application requirements. The above list displays the most common/standard seal combinations used. Viton® - Registered trademark of E.I. DuPont De Nemours & Company Gylon® - Registered trademark of Garlock, Inc.

Abrir o catálogo na página 9

D = STUFFING BOX BORE J = LENGTH TO OBSTRUCTION R = STUFFING BOX DEPTH HOUSING E = STUFFING BOX BORE DEPTH FACE PLATE L = STUD LENGTH FACEPLATE S = SHAFT DIAMETER HOUSING F = FACEPLATE SHAFT DIAMETER M = LENGTH TO OBSTRUCTION V = STUD LENGTH H = LENGTH TO OBSTRUCTION FACEPLATE SIDE K = STUD INFORMATION W = LENGTH TO NEAREST OBSTRUCTION

Abrir o catálogo na página 10

NPSHr (Feet of Water) Pump Speed (RPM) Version 1.7

Abrir o catálogo na página 11

Priming Ability of HD Series Pumps Performance curves indicating priming ability of pumps based on test data obtained on new pumps. Priming ability of older pumps, because of larger clearances, will not be as good. DUCTILE IRON (STD. CLEARANCE) DUCTILE IRON (HOT CLEARANCE) STAINLESS STEEL (STD. CLEARANCE) STAINLESS STEEL (HOT CLEARANCE)

Abrir o catálogo na página 12

Horsepower Multiplying Factor Vs. Viscosity BHP Multiplying Facto

Abrir o catálogo na página 13

SINGLE LOBE IMPELLERS NEEDED

Abrir o catálogo na página 14

The Tuthill process pump is ideally suited for slurries, since it is capable of handling a wide range of apparent viscosities and solid particle sizes. When sizing a process pump, you must determine the viscosity of the carrier fluid, particle size, and particle hardness. The thicker the carrier fluid, the less recirculation of product through the fluid chamber clearances (slip), thus there is less erosive wear from any abrasive particle. If the carrier fluid is water thin, the abrasive particles are allowed to re-circulate in the clearances, resulting in a short wear life. Particle size...

Abrir o catálogo na página 15

Available Options: • Packing: Pure PTFE, Graphite, other special materials available on request • Shaft: Steel, Armco 17-4PH, 316 S.S. (all have ceramic coating option) • Style #1 packing is the standard for all HD models

Abrir o catálogo na página 16

Style #2 (Lantern Ring) Recommended Usage: • Grease lubrication improves sealing and packing life • Vent to suction side of pump to reduce pressure on outboard packing • Flush with clean fluid at 15-20 PSI above pump discharge pressure • Some product dilution will occur so compatible fluid must be used This design is the same as Style #1 except lantern ring and "in" and "out" flush connections are provided in the approximate location shown. A minimum of two rings of packing will be installed inboard to throttle flow. Standard lantern ring material is glass filled PTFE. Rings may be made in...

Abrir o catálogo na página 17

Construction The jacket has a fabricated carbon steel plate type insert with an aluminum cast outer shell. Jacket is made in two-piece construction for field installation and/or pump maintenance access. Each half has V2" NPT (internal) in and out ports. Rating: • Steam or heat transfer fluids • 150-PSI maximum pressure • 500°F maximum temperature

Abrir o catálogo na página 18

Factory or field installed. Standard grade Thermon or other heat transfer cement is applied between pump and jacket for best efficiency. Applications where pumped fluid must be maintained at temperature in order to remain in liquid form so the pump can pump the fluid are ideal for a steam jacket. General Ph Chart

Abrir o catálogo na página 19

* Max. Case Pressure for Standard Duty models with wing nuts is 150 PSI for Stainless Steel and 200 PSI for Ductile Iron. 500 PSI rating can be achieved by replacing wing nuts with standard hex head nuts torqued to industry standards. Flange Ratings (Cast Iron) Temperature (deg C) This chart shows the ratings for flanges only - the maximum pump operating conditions must also be checked. Consult the appropriate Tuthill catalog for maximum allowable operating pressures and temperatures, based on pump application conditions and pump features. These ratings are based on non-shock...

Abrir o catálogo na página 20

Flange Ratings (Stainless Steel) Temperature (°C) -45 ThIs chart shows the ratings for flanges only - the maximum pump operating conditions must also be checked. Consult the appropriate Tuthill catalog for maximum allowable operating pressures and temperatures, based on pump application conditions and pump features. These ratings are based on non-shock pressures. ANSI data is from ASME/ANSI B16.5 - 1988 (matl group 2.2). Consult this spec for more information. WARNING Rapid temperature change can result in flange failure and leakage, which can cause property damage or serious injury. Do not...

Abrir o catálogo na página 21Todos os catálogos e folhetos técnicos Tuthill

-

Magnetically Coupled Precision Pumps

6 Páginas

-

HD Series Pumps

39 Páginas

-

4000 Series Pumps

18 Páginas

-

Lubrication & Circulation Pumps

6 Páginas

-

1008 & 1010 Size Pumps

9 Páginas

-

Product Line Brochure

6 Páginas

-

GlobalGear® Series

6 Páginas

-

Tuthill Plastic Group

6 Páginas

-

D Series Pump

3 Páginas

-

PRECISION METERS & ACCESSORIES

8 Páginas

-

Performance Curves - 1000 Series

16 Páginas

-

Engineering Data Pack - TR Series

21 Páginas

-

Engineering Data Pack - M Series

23 Páginas

-

Engineering Data Pack - GlobalGear® US

35 Páginas

-

TT10 In-Line Digital Turbine Meter

4 Páginas

-

FR1118P10 In-line Meter

1 Páginas

-

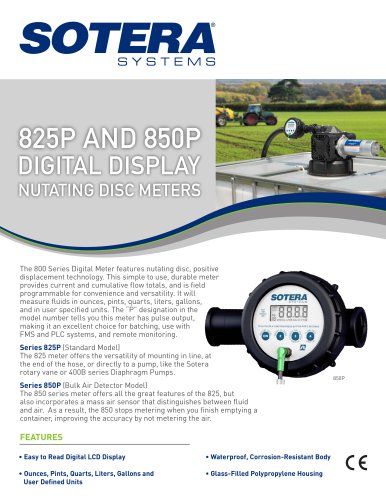

825P 850P Sotera Digital Meters

2 Páginas

-

Series 800 Digital Flow Meter

4 Páginas

-

Tuthill Precision Meters

8 Páginas

-

Performance Curves - CC Series US

8 Páginas

-

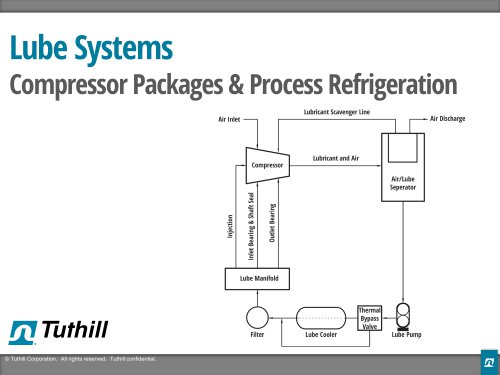

Presentation - Lube Systems

9 Páginas

-

Full Line OEM & Process Applications

6 Páginas

-

Sotera Air Operated Diaphragm Pump

7 Páginas

-

L & C SERIES

6 Páginas

-

Heavy Duty Series

6 Páginas

-

2016 D, T, & P SERIES

6 Páginas

-

1000 SERIES

6 Páginas

-

White Paper - Pulp & Paper

2 Páginas

-

Whitepaper - Polyurethane Foam

7 Páginas

-

White Paper - Asphalt

3 Páginas

-

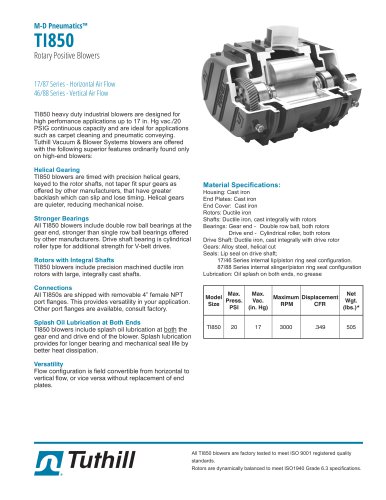

TI850 TH-063

2 Páginas

-

QX TH-094

2 Páginas

-

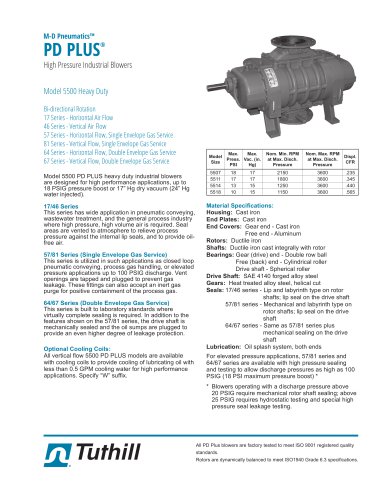

PD Plus 9000 TH-052

2 Páginas

-

PD Plus 7000 TH-051

2 Páginas

-

PD Plus 5500 TH-050

2 Páginas

-

PD Plus 3200 TH-048

2 Páginas

-

PD Plus 1200 TH-047

2 Páginas

-

MD Pneumatics blower

2 Páginas

-

PneuPak TH-056

2 Páginas

-

PneuMax II TH-055

2 Páginas

-

Equalizer RM TH-045

2 Páginas

-

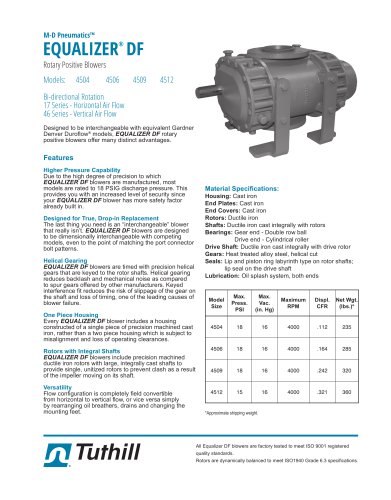

Equalizer DF TH-046

2 Páginas

-

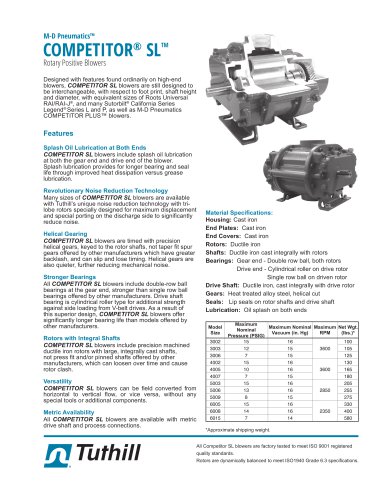

Competitor SL TH-044

2 Páginas

-

Competitor Plus TH-043

2 Páginas

-

Blowers & Vacuum Boosters TH-040

8 Páginas

-

TuffSeall

2 Páginas

-

M Series

2 Páginas

-

HD Series

6 Páginas

-

Full Line

6 Páginas

-

Dry Bulk Truck Blowers TH-074

4 Páginas

-

Vacuum Pumps Brochure TH-004

8 Páginas

-

atlantic fluidics

16 Páginas

-

KDS Dry Screw Vacuum Pump

3 Páginas

-

Vacuum Pump Selector Guide

6 Páginas

-

KTLP/VFP Series

2 Páginas

-

Kinney® KMBD Vacuum Boosters

2 Páginas

-

Liquid Ring Vacuum Pumps

16 Páginas

-

Rotary Piston Vacuum Pumps

18 Páginas

-

Mechanical Booster Vacuum Systems

8 Páginas

-

Process Gear pumps

6 Páginas

-

1000 Series Lubrication Pumps

6 Páginas

-

CC Series Close Coupled Pumps

2 Páginas

-

T950H Brochure

4 Páginas

-

T650 Product Brochure

4 Páginas

-

Qube Product Brochure

6 Páginas

-

MD Pneumatics Blower Selector Guide

2 Páginas

Catálogos arquivados

-

GlobalGear® Series

6 Páginas

-

2015 D, T, & P Series

14 Páginas

-

Series 1000

6 Páginas

-

T850/T1050 Truck Blowers

4 Páginas