Excertos do catálogo

CEMA Series C2000 Idlers Bearings • Link-Belt® CEMA C Rolls contain 6304 deep groove ball bearings, which have a 20% higher basic dynamic load rating than the commonly used 6204 bearing. Frames • Inverted angle frame base with slotted foot straps to ensure quick, easy mounting and alignment Heavy-duty, die-formed, steel end brackets are contoured for generous clearance to safeguard against spilled materials becoming jammed and impeding the rotation of the rollers All idler frames are welded in accordance with AWS D1.1 specifications for structural welds Rubber double lip contact seal paired with a polymer deflector with integrated labyrinth seal for robust, redundant sealing capability Seal works well in dusty conditions and wash down environments Frames and rolls are powder-coated (see page 155 for details) Assembly hardware is electro-zinc plated Idlers meet or exceed CEMA requirements for rugged, continuous material handling Multiple belt widths and models available to meet your needs Roll Thickness • Testing Capabilities • Load rating Seal life Roll concentricity Roll resistance Roll imbalance Water resistance Pressed Head: Precision formed pressed head. Designed to provide strength and rigidity while offering reduced weight. Excellent roll concentricity and balance. Yellow Zinc plated for corrosion resistance. Deflector: Impact and corrosion resistant deflector provides first line protection against abrasive materials and washdown water. Triple Labyrinth Seal: Durable, zinc plated inner metal labyrinth seal serves to fling out material and water while providing a smooth, corrosion resistant, heat conductive surface for the contact seal. Contact Lip Seal: Special wear resistant contact seal provides sealing against abrasive fines and washdown water. Suitable for dry, wet, and cold temperature conditions. Solid Shaft: High strength, cold finished low carbon C1018 shafting. Broached shaft end slots anchor the roll assembly securely to the frame. Retaining Ring: Corrosion resistant stainless steel retaining ring eliminates any possible shaft end-play while firmly securing the roll assembly under load. Deep Groove Bearings: Distance from the bearings and shaft ends is minimized to reduce shaft deflection at the bearings. Standard 2RS rubber seals add another level of protection against material and water. C2000 / 6304-2RS / 20mm Dimensions subject to change without notice. Certif

Abrir o catálogo na página 1

Carrying Idler Types Troughed belt idlers for general carrying service are available with roll inclinations of 20˚, 35˚, and 45˚. Troughed belt training idlers automatically train belts and protect belt edges from damage caused by misalignment. Positive action type available for belts operating in one direction, and actuating shoe type available for twodirectional operation (reversing). Variable troughed belt idlers placed between the final troughing idler and the head pulley, support the belt during its transition from a concave to a flat contour. The end rolls can be adjusted vertically...

Abrir o catálogo na página 2

CEMA C idlers of every type to meet your specific needs… Syntron Material Handling Model Number CAUTION: Link-Belt Conveyor Idlers must be installed, operated and maintained in accordance with Syntron Material Handling Service Instructions. Failure to follow these instructions can result in serious personal injury, property damage or both. Syntron Material Handling Service Instructions are available for download at www.syntronmh.com. Dimensions subject to change wit

Abrir o catálogo na página 3

Flat Carrying Training Positive Training Reversing Picking & Feeding Live Shaft Rubber Cushion (Impact) Rubber Tread

Abrir o catálogo na página 4

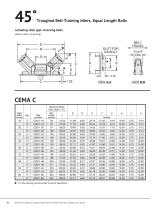

Troughed Belt Idlers, Equal Length Rolls steel rolls ** To top of discharge or bend pulleys, except tail pulley. ■ 7.5" bolt spacing recommended to permit adjustment. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 5

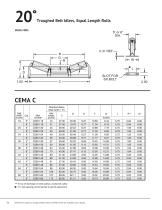

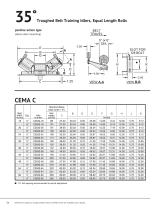

Troughed Belt Training Idlers, Equal Length Rolls positive action type (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment.

Abrir o catálogo na página 6

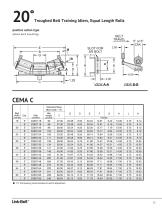

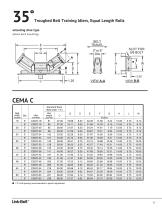

Troughed Belt Training Idlers, Equal Length Rolls actuating shoe type reversing belts (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 7

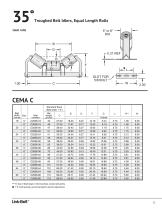

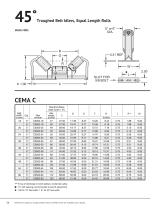

Troughed Belt Idlers, Equal Length Rolls ** To top of discharge or bend pulleys, except tail pulley. ■ 7.5" bolt spacing recommended to permit adjustment.

Abrir o catálogo na página 8

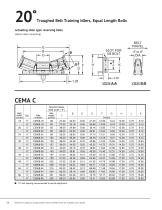

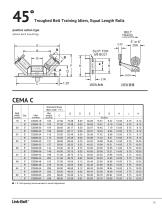

Troughed Belt Training Idlers, Equal Length Rolls positive action type (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 9

Troughed Belt Training Idlers, Equal Length Rolls actuating shoe type (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment.

Abrir o catálogo na página 10

Troughed Belt Idlers, Equal Length Rolls ** To top of discharge or bend pulleys, except tail pulley. ■ 7.5" bolt spacing recommended to permit adjustment. ♦ 1.69 for 18" belt width; 1.31 for 20" belt width. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 11

Troughed Belt Training Idlers, Equal Length Rolls positive action type (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment.

Abrir o catálogo na página 12

Troughed Belt Training Idlers, Equal Length Rolls actuating shoe type reversing belts (above deck mounting) ■ 7.5" bolt spacing recommended to permit adjustment. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 13

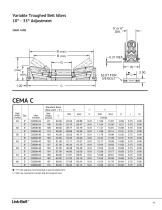

Variable Troughed Belt Idlers ■ 7.5" bolt spacing recommended to permit adjustment. □ Shim as required to contact belt and support load.

Abrir o catálogo na página 14

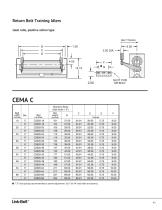

Return Belt Idlers steel rolls ■ 7.50" bolt spacing recommended to permit adjustment. Dimensions subject to change without notice. Certified prints are available upon request.

Abrir o catálogo na página 15

Return Belt Training Idlers steel rolls, positive action type BELT TRAVEL ■ 7.5" bolt spacing recommended to permit adjustment. (8.5" for 54" belt width and above).

Abrir o catálogo na página 16Todos os catálogos e folhetos técnicos Syntron Material Handling

-

Syntron® Vibrating Conveyors

24 Páginas

-

Vibrating Screens Catalog

36 Páginas

-

Screw Conveyor Catalog

6 Páginas

-

Bin Vibrator Catalog

30 Páginas

-

Paper Joggers Catalog

20 Páginas

-

Material Handling

2 Páginas

-

Vibrator Flowaids

30 Páginas

-

Syntron Vibrating Tables

6 Páginas

-

Syntron Vibrators

48 Páginas

-

Syntron Screen Feeders

6 Páginas

-

Belt Conveyor Idler

160 Páginas

-

Syntron High Velocity

2 Páginas

-

Syntron Jogger

20 Páginas

-

Syntron Vibrating Screens

36 Páginas

-

CEMA Series E4000 Idlers

36 Páginas

-

Introducing Composite Idler Rolls

2 Páginas

-

CEMA Series B2000 Idlers

22 Páginas

-

Ball Bearing Idlers

8 Páginas

-

Working with Isolation

20 Páginas

-

Aggregates

20 Páginas

-

Coal Handling

20 Páginas

-

Syntro-Flo

2 Páginas

-

Syntron Heavy-Duty Vibrating Feeders

40 Páginas

-

Syntron Light Industry Vibrating Feeders

28 Páginas

-

Link-Belt Bucket Elevator

26 Páginas

-

Working with Hoppers

28 Páginas

-

Syntron Power Pulse Control

2 Páginas

-

Syntron Heavy-Duty Feeders Catalog

40 Páginas

-

C2000

2 Páginas

-

Link-Belt Screw Conveyor

101 Páginas

-

Link-Belt Underground

32 Páginas

-

Link-Belt Idler

160 Páginas

-

Syntron® Vibrators

48 Páginas

Catálogos arquivados

-

PowerPulse WT

2 Páginas

-

HV-10

2 Páginas