Excertos do catálogo

Sika Facade Systems Sealing and Bonding in Facades - Specification Guide

Abrir o catálogo na página 1

Glazing Technologies Supplementary curtain wall solutions Ancillary Products Peek & Cloppenburg Store, Cologne, Germany

Abrir o catálogo na página 3

Sika’s Sealing and Bonding Solutions – for Facades in every Climate Projects on this page: 1 Peek & Cloppenburg Store, Cologne, Germany 2 30 St. Mary Axe, London, UK 3 Zhang Jiang Hi-Tec Park, Shanghai, China 4 New Exhibition Center Milan, Italy 5 National Swimming Center (Water Cube), Beijing, China 6 Equity Tower, Jakarta, Indonesia 7 Crystal Tower, Manama, Bahrain 8 Russia Federation Tower, Moscow, Russia 9 One Marina Boulevard (NTUC Building), Singapore Front page: ADAC Head Quarters, Munich Germany

Abrir o catálogo na página 4

High-Tech Solutions for Perfect Facades Architecture thrives on change. On creative ideas and bold solutions that fascinate and surprise us every time. Curtain walls are a particularly severe challenge for planners, because they not only set the character of the structure but must also meet stringent requirements. Creative Facade Architecture To strike the ideal balance between aesthetic appeal and energy efficiency, architects are increasingly turning to glass for curtain wall construction. As transparent structural glazing walls, single or double glazed or even double skin facades. Glass...

Abrir o catálogo na página 5

For structural glazing silicone adhesive sealants Sikasil® SG see page 16. Four-Sided Structural Glazing Two-Sided Structural Glazing Optimum Transparency Optimum Safety Structural glazing systems can be either two-sided or four-sided, with each design having its own particular advantages. In general, for efficient and energy-saving building management, double and triple glazing is recommended. Frameless Appearance Four-sided structural glazing is impressive first and foremost because of its monolithic frameless appearance. All four sides of the large-format pane element are bonded to an...

Abrir o catálogo na página 6

13 For UV-resistant weather sealing between the glass panes with Sikasil® WS silicones see page 27. 14 For the appropriate fin glazing silicone sealants Sikasil® SG and Sikasil® WS see page 30. 15 For details of window bonding see www.sika.com/windows Bolt-Fixed Glazing Total Vision Glazing Structural Window Bonding Frameless Appearance Slim and Energy Efficient Design Mechanical Fixing In bolt-fixed glazing systems, the glass elements are fixed to cable systems or metal beams by metal fasteners. These fasteners are embedded in holes in the glass pane with “glass cement”. The glasses can be...

Abrir o catálogo na página 7

16 Stock Exchange; Johannesburg, South Africa 17 Zorlu Plaza, Istanbul, Turkey Structural Glazing – Sophisticated Architecture and Innovative Technology Structural glazing modules are subject to extremely high stresses. They must accommodate wind and snow loads as well as thermal expansion, and permanently transfer the forces to the support structure, while also withstanding weathering over many years. Specialized Products Durable Construction High-modulus Sikasil® SG silicone adhesive sealants offer the best properties for this purpose. The latest development with highest design factor is...

Abrir o catálogo na página 8

Adapter frame Stepped insulating glass unit Secondary edge seal Setting block Spacer tape Mechanical support Structural glazing joint Backing material Setting block Structural glazing joint Spacer tape Symmetrical double glazing unit The illustration shows a structural glazing module prototype. This diagram is not intended as a construction guide. More elaborate, additional structural elements may be needed to satisfy national construction regulations or project-specic requirements. Economical Construction Integrated Systems Structural glazing facades have both technical and economical...

Abrir o catálogo na página 9

18 Airport Barajas Madrid, Spain; Richard Rogers & Estudio Lamela Joint Design – Correct Planning is Essential In structural glazing, the adhesive joints should be planned and arranged according to optical requirements, but they should also take into account dimensional changes in the adjacent parts under the effect of temperature and the movement capability of the silicone adhesive. The joint design thus combines shape with functionality. Important Seven criteria must be observed: 1. The joint seal must be able to freely accommodate tensile and compressive movements between the joint...

Abrir o catálogo na página 10

h e h joint bite e joint thickness 18 Airport Barajas Madrid, Spain; Richard Rogers & Estudio Lamela Calculating the Joint Bite h Typical Stress/Strain Diagram ofwind Joint bite h as a function of the Sikasil®supported constructions: load in SG-500 Joint bite h as a function of the dead load in non-supported constructions: Joint bite h as an interaction of combined tension and shear load: Mohr tension cycle minimum bite of the adhesive joint (mm) minimum bite of the adhesive joint (mm) length of the short edge of the glass pane or of the element (mm); with irregularly dimen- sioned glass...

Abrir o catálogo na página 11

A Right joint dimension in its original state (h = joint bite, e = joint thickness) B Besides tensile movements the adhesive bond C also absorbs shear movements in all directions. D It is essential that bonding on three sides is avoided. Glass pane Structural glazing joint Calculating the Joint Thickness e With all structural glazing constructions, the adhesive bond is subject to considerable shear movements. The joint thickness (glue line thickness) must therefore be designed so that the movement capability is not exceeded. Criteria for Calculating the Joint Thickness e - Dimensions of the...

Abrir o catálogo na página 12

Calculation Values for Sikasil® SG and Sikasil® IG products ETAG Movement capability (ASTM C719) 3b. Calculation of the minimum Joint Thickness e (ETAG 002) The calculated deformations of the long and short panel edges yield the total movements according to the formula above (Pythagoras’ theorem). ∆l = total change in length v = vertical h = horizontal 3a. Calculation of the minimum Joint Thickness e (ASTM C1401) Sikasil® SG silicone adhesive sealants are permitted maximum elongation of ±12.5% (c = 0.125). The total of expansion and contraction must not exceed 25%. With these restrictions,...

Abrir o catálogo na página 13Todos os catálogos e folhetos técnicos SIKA INDUSTRY

-

Sikasil® SG-20

2 Páginas

-

sikia

2 Páginas

-

glass

5 Páginas

-

Sikasil® WS-605 S

4 Páginas

-

BONDING EXCELLENCE

4 Páginas

-

AUTO GLASS REPLACEMENT

28 Páginas

-

ASSEMBLY LINE ADHESIVES

9 Páginas

-

ACOUSTIC SYSTEMS

9 Páginas

-

SikaFast®-5221

2 Páginas

-

Sika®Aktivator

2 Páginas

-

SikaLastomer®-710

2 Páginas

-

Sikaflex®-221

2 Páginas

-

Fenestration Systems

12 Páginas

-

Fast Reaction, Superior Strength

5 Páginas

-

SikaForce®-7718 L100

2 Páginas

-

Sikaflex®-290i DC

2 Páginas

-

Sikasil® WS-355

2 Páginas

-

Sika® Primer-290 DC

2 Páginas

-

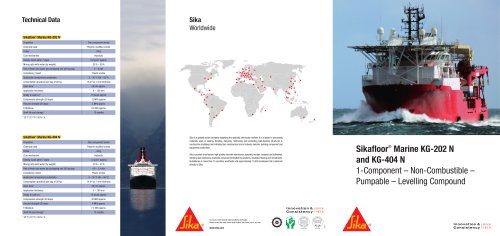

Solar Solutions

12 Páginas

-

Automotive - Realising Visions

20 Páginas

-

Sikaflex® - General Guidelines

12 Páginas

-

Sika Industry - Inventing the Future

15 Páginas

-

Industry Product Catalogue

20 Páginas

-

Sikkagard 700S

3 Páginas

-

SikaTack® Drive

2 Páginas

Catálogos arquivados

-

SikaMelt®-601

2 Páginas

-

Sikaflex®-521 UV

2 Páginas

-

Sika hotmelt

5 Páginas

-

Product Catalogue

20 Páginas