Excertos do catálogo

we make processes work

Abrir o catálogo na página 1

ISchenck Process Group -your partner worldwide. Acting locally to support your needs, Schenck Process is working where you are. With an unrivaled global network of operating companies and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for weighing, feeding, conveying, screening, automation and air filtration technology. Whether you are planning processing plants, feeding bulk solids, controlling material flow, recording commodity flow, weighing goods or automating manufacturing and...

Abrir o catálogo na página 2

Leading solutions for a wide range of industrial sectors. These days virtually every sector of industry requires precise accuracy in bulk material handling and air filtration. Whether it’s precisely fed powders for pharmaceutical manufacturing, producing the optimum rubber for tires, or reducing explosive dust in a sugar processing plant – Schenck Process makes processes work. The Schenck Process Group is a global market leader in industrial weighing and feeding technology /// screening and separation systems for bulk materials /// dust collection and air filtration technology /// pneumatic...

Abrir o catálogo na página 3

Unshakable. Under the Harshest Conditions. Our solutions for cement, gypsum, sand and gravel, steel and non-ferrous metals, bulk material handling, filtration and RailTec. Bulk material handling involves feeding, screening and conveying from the finest to the most complicated materials in the manufacture of cement, building materials, steel and non-ferrous metals. Schenck Process has a proven track record for handling those materials in the most challenging environments. Dust collection is handled by a wide range of filtration products that can satisfy requirements from a single point...

Abrir o catálogo na página 4

Manufacture of steel Highly efficient weighing, feeding, conveying, pneumatic injection and screening technology for all relevant process stages. Production of pig iron Weighing and feeding technology is the foundation for highest product quality and process stability. Cement blending Perfect cement is the result of processes where Schenck Process equipment plays a major role. Materials are mixed, fed and metered accurately. Pneumatic injection technology is available for additive blending. Feeding of powered materials for environmental control systems Feeding consistency for high product...

Abrir o catálogo na página 5

When accuracy counts. Our solutions for chemicals, food, pet food, pharmaceuticals and plastics. High-tech solutions for weighing, feeding, pneumatic conveying and filtration Precisely handled bulk materials are critical to the manufacture of chemicals, food, pet food, pharmaceuticals and plastics. Our adaptable high-tech solutions are specially designed for this complex task. Whether you need a gravimetric feeder, weighbelt, dilute or dense phase conveying system or a dust collector – we have the right solution to meet your specific needs. Complex process, precise solutions Our weighing...

Abrir o catálogo na página 6

Plastics Precision feeding and conveying for accurate dosing of additives in plastic processes. Easily disassembled feeders are perfect for multiple process changeovers. Polyester production Precision feeding processes are a necessity in polyester production. By combining Schenck Process feeders and mass flow meters, the ideal system is possible. Food industry Whether conveying sugar or feeding cereal products, Schenck Process has the experience to design and build the ideal system for your food processing application. Pet food batching When making a choice for pneumatic conveying,...

Abrir o catálogo na página 7

Durable, robust and extremely reliable under the toughest of conditions. Our solutions for coal, iron ore, base metals and minerals. The processing of non-ferrous metals, applications in coal mining, preparation in mines and loading of the finished products require technology and materials capable of withstanding the most extreme conditions. Schenck Process solutions prevail where others give up. Our products are durable and extremely reliable with high availability under the most difficult conditions. Whether large lumps or the finest grain, wet or dry and irrespective of whether using...

Abrir o catálogo na página 8

Coal preparation plants Schenck Process provides services for site design, detailed engineering, manufacturing and procurement of equipment, site project management and commissioning, as well as full turnkey packages. Screening Schenck Process provides state-of-the-art screening technology with G-force exciters and robust design, coupled with in-house manufacturing and application experience of screen panels. Train loading systems Schenck Process offers customized bin designs, integrated weighing systems for fast, safe, consistent and highly accurate rail car loading, as well as l...

Abrir o catálogo na página 9

Efficient. Safe. Precise. Our solutions for coal- and biomass-fired power plants, electric utility and process industries. With the most trusted brands in the industry, Schenck Process offers a diverse range of bulk material handling systems, equipment and components to cover almost any need in the power industry. Our material handling systems convey millions of tons of raw material annually including coal, limestone, biomass and alternative fuels. Our products are also used to handle plant by-products such as ash and gypsum. Schenck Process material handling solutions offer a wide variety...

Abrir o catálogo na página 10

Gravimetric and volumetric coal feeding systems for boilers Feed system design and fabrication to meet the needs of your plant regardless of system size. Biomass and EFW WTE fuel feeding and handling / Fuel handling, dosing and feeding systems regardless of fuel type. Power supplies and ESP controls Integrated precipitator control systems and power supplies to maximize your ESP particulate collection efficiency. Ash handling The unique dense phase technology safely and economically handles high volumes of ash. Mechanical conveying for the power industry Bulk material handling systems with...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

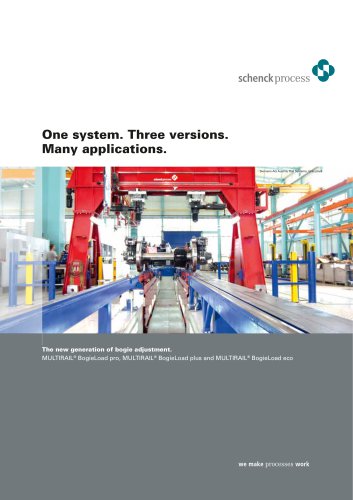

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas