Excertos do catálogo

Train loader (TLO) – economic loading Accurate, high-speed loading systems for any application

Abrir o catálogo na página 1

Zero tolerance to loading mistakes! We know that accuracy is paramount here, often more so than in other situations. When mine operators in Australia need to load train sets with 5 locomotives, 234 rail cars and a length of almost 3 km for transport to the port, each rail car has to be precisely loaded – not too light and not too heavy. Schenck Process equipment is used around the globe, e.g. in Australia, South America or China. A large amount of the ore mined by global companies is weighed and loaded using Schenck Process technology. •• Fully automatic gravimetric operation •• Feed rate...

Abrir o catálogo na página 2

Reliable operation under harshest conditions minus 20 in China ˚C Schenck Process train loaders are designed to operate reliably in the harshest mining environments. High temperatures, dust and water are commonplace in the mining industry. Schenck Process train loaders will operate reliably for extended periods and require only routine maintenance. Schenck Process train loaders feature high quality corrosion resistant paints, environmentally sealed electrical equipment, and high quality hydraulic components. heavy rainfall in Brazil Low maintenance requirements •• High quality corrosion...

Abrir o catálogo na página 3

System design Train loader (TLO) and MULTIRAIL® TrainLoadOut – perfect teamwork Train loader (TLO) combined with world leading weighing technology using MULTIRAIL® TrainLoadOut offers complete control and automation with accuracies of ±0.5 % of the total train weight. Weighing rail cars before and after loading provides a complete picture of axle loads and total train weight as well as any material hang-up that can overload a rail car. Integration into on-site ERP systems ensures that operations are running smoothly and to optimum efficiency. Fully automatic rail car loading software...

Abrir o catálogo na página 4

Material handling expertise We have been involved in around 80% of all train load out operations for almost 20 years. The Schenck Process loading systems experts have extensive know-how in materials handling and stockpile reclaim systems. Schenck Process’ engineers support customers with materials handling system design, thereby optimizing operation of the reclaim system and train loader while at the same time considering capital expenditure constraints. Schenck Process can also incorporate electrical and PLC control of the clients’ materials handling system into the train loader design if...

Abrir o catálogo na página 5

schenckprocess The Schenck Process Group is a global leader in weighing and feeding technology III screening and separation systems for bulk materials III dust collection and air filtration technology III pneumatic and mechanical conveying solutions III automation and diagnostic technology we make processes work © Schenck Process GmbH, 2016 BV-P 2124 GB “M6 ■ A" in.f°rmation is given without option.

Abrir o catálogo na página 6Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

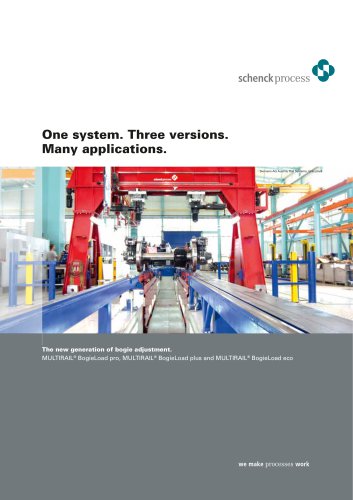

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas