Excertos do catálogo

The Original Dome Valve Range Material Isolation Valves for Pneumatic Conveying Systems and Bulk Handling Applications

Abrir o catálogo na página 1

Schenck Process Group - Your Partner Worldwide Acting locally to support your needs the Schenck Process Group is working where you are. With a global network of sites and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for industrial weighing, feeding, conveying, screening, automation Our key skills include planning processes, feeding bulk materials, controlling flows of material, recording flows of goods, weighing goods and automating transport processes. Members of the Schenck Process Group...

Abrir o catálogo na página 2

To date, more than 40,000 Original Dome Valves have been sold worldwide, for applications across a range of industries including: food, pharmaceuticals, chemicals, plastics, minerals, power, iron and steel. The Original Dome Valve Range The most effective bulk material handling valve in the world. The highly innovative and well proven Original Dome Valve from Schenck Process is reputably the most effective fast closing, bulk material handling valve in the world. The Original Dome Valve was developed by Clyde Materials Handling* in 1974 for use with pneumatic conveying systems and as a...

Abrir o catálogo na página 3

Wide Range of Process Applications Industry applications The Dome Valve is suited to applications in a wide range of industries from food, pharmaceutical to mineral and plastics to metals. Capable of cutting through flowing material and some static columns, the valve handles abrasive, cohesive, fine and dry products with equal ease. High reliability with minimal maintenance The Original Dome Valve has a world-wide reputation for reliability. This results from its simple, cavity-free construction which is designed to minimise the possibility of material build-up within the valve body. The...

Abrir o catálogo na página 4

Seal Operating Sequence The range of materials that can be handled include • Detergents • Minerals • Ores • Chemicals • Fly ash • Granules • Powders • Sand • Additives • Electronic scrap • Dusts • Pulverised coal/granular coal • Cement • Gypsum Dome closed, seal inflated The seal automatically inflates only when the dome is fully closed. Dome closing, seal deflated The seal automatically deflates during opening and closing, thereby avoiding contact with the dome and eliminating unnecessary wear.

Abrir o catálogo na página 5

Extensive Range of Dome Valve Product Options Chrome or ENP Epoxy resin For sticky and abrasive materials For corrosive materials Tungsten carbide or ENP Reinforced PTFE For abrasive materials For food, sticky or wet materials Choice of 'dome' finishes to handle a wide range of materials These coatings can also be extended to the internal surfaces of the valve body and Materials from fine abrasive powders to a very cohesive substances may require different 'dome' finishes in terms of raw material or surface coatings. The dome is usually produced from SG iron or stainless steel, but other...

Abrir o catálogo na página 6

Dump valves and terminal boxes Dump valves are used where a number of hoppers positioned in series require selective feeding. They have two operating conditions, ‘straight through’ and ‘dump’. In the straight through condition, a self-inflating easily replaceable seal closes off the respective hopper inlet, allowing the material to be conveyed ‘straight through’ to the next available reception point. Switch valves These types of valves are used for diverting flow in any pneumatic conveying lines or hopper discharge applications and are particularly suitable for abrasive materials. They can...

Abrir o catálogo na página 7

02.14 · All information is given without obligation. All specifications are subject to change. BV-P 9019 GB Schenck Process UK Ltd Carolina Court, Lakeside Doncaster, DN4 5RA, United Kingdom T +44 (0)1302 321 313 F +44 (0)1302 554 400 enquiries@schenckprocess.co.uk www.schenckprocess.co.uk Schenck Process GmbH Pallaswiesenstr. 100 64293 Darmstadt, Germany T +49 61 51-15 31 0 sales@schenckprocess.com www.schenckprocess.com © by Schenck Process GmbH, 2014 The Schenck Process Group is a global market leader in industrial weighing and feeding technology /// screening and separation systems for...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

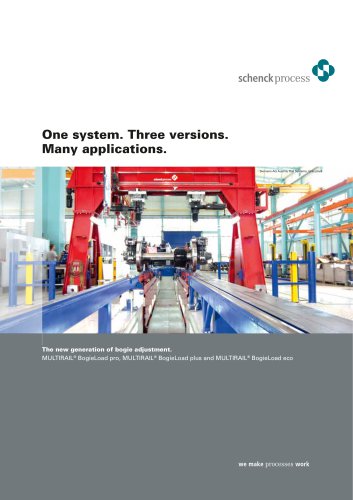

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas