Excertos do catálogo

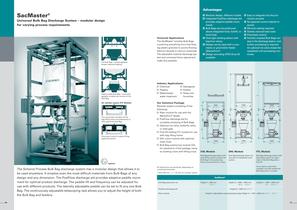

Universal Bulk Bag Discharge System for varying process requirements - modular design The Schenck Process Bulk Bag discharge system has a modular design that allows it to be used anywhere. It empties even the most difficult materials from Bulk Bags of any design and any dimension. The PosiFlow discharge aid provides adaptive paddle move- ment for optimal product discharge. The paddle lift and frequency can be adjusted for use with different products. The laterally adjustable paddle can be set to fit any size Bulk Bag. The continuously adjustable telescoping rack allows you to adjust the height of both El Modular design, different models E! Integrated PosiFlow discharge aid provides adaptive paddle move- El Bulk Bags can be positioned above integrated hoist, forklift, or local hoist El Dust-tight docking station with 13 Design can be used with a volu- metric or gravimetric feeder 13 Design according ATEX Zone 22 El Easy to integrate into the pro- duction process El No separate control cabinet re- E9 Minimal cabling required El Greatly reduced total costs El Partially emptied Bulk Bags can stay in the discharge station until further processing is required. An optional iris valve closes the receptacle until processing con- Universal Applications The SacMaster" empties Bulk Bags containing everything from free-flow- ing plastic granules to poorly-flowing titanium dioxide or calcium carbonate. The adjustable material discharge sys- tem and universal frame adjustment make this possible. Industry Applications: water treatment foundries Modular system consisting of the 13 Riser module for use with the MechaTron® feeder complete emptying of Bulk Bags El Optional iris valve, butterfly valve, El Fork-lift loading FTL module for use with bag-lifting frame El DHL crane module with optional chain hoist El Bulk Bag positioning module CHL for placement of the package using an existing crane with lifting cross. Bulk Bag discharge station with load-lifting system to place the frame using customer's crane. Bulk Bag discharge station for use with an integrated crane All dimensions are standards, depending on customized execution * Note 200 mm (7.9") lift with air cylinder system Bulk Bag discharge station with bag-lifting system for place- ment of the Bulk Bag with a fork lift. cylinders can fully extend the Bulk Bag once it is empty. Riser module (height is adjustable using telescoping legs) Height A = 1100 - 2500 mm (43.3" - 98.4")

Abrir o catálogo na página 1Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas