Excertos do catálogo

Precise weighing, feeding and measuring solutions for thePharmaceutical Industry. we make >

Abrir o catálogo na página 1

Based on a platform of repeatedly satisfied customers, the following are our keysuccess factors: Key Success Factors Global network of 24 national companiesco-operating to improve our customerёs processes and results Core competencies in bulk solids handling, weighing, feeding, measuring and automation Sales, technical support and service close to the customer Best-in-Class and unrivalled range of weighing, feeding and screening equipment designed to optimally handle the widest possible range of materials Excellence in project management Best-in-Class design, manufacturing and assembly >

Abrir o catálogo na página 2

Technological Leadership through a commitment to R&D With technological leadership and innovation being central to our business, R&D plays a pivotal role in our success. Following this philosophy, we work closely with our customers to ensure that our products, used to satisfy their applications, exceed expectations in terms of accuracy, consistency and reliability.Through these close working relationships, we have continuallyexcelled at inventing and advancing award-winning product and system designs that feature the quality, versatility, cleanability and performance that is required by...

Abrir o catálogo na página 3

How did we create the best pharmaceutical-grade dry solids feeders? Simple. We asked an international group ofpharmaceutical manufacturing and process experts to help us define what todays processes require. Then, with their guidance, we developed new patented technology to deliver it for jet milling, blending, extruding, packaging, coating and formulating applications. The results Җ the new PureFeed > dry solids feeders. > Material discharge: Feeding disc (patent pending). Innovative technology especially designed to excel in handling low feed rates.Application Parameters Ideal for low...

Abrir o catálogo na página 4

Both feeders feature: 316L Stainless Steel material pcp Ra 0.8 m interior finishes(Ra 0.4 > Material discharge:Established Auger and Wire Helixԓ(patent pending).Feed Hopper:Flexible and disposable. m optional) Completely enclosed motors Sanitary quick release clamps Easy disassembly and cleaningin minutes Smooth wipe down friendly surfaces Explosion proof configurations (optionally available) Application examples: Regulating material supply to sizereduction equipment Feeding active and excipient ingredients into batch and continuous mixer/blenders Extrusion and compounding Tabletting and...

Abrir o catálogo na página 5

The provision of the correct validation documentation is at least as important as the choice of the correct process equipment. That is why we make sure the supply of our equipment is cost effectively supported with the appropriate levels of validation documentation: certificates of conformity, IQs, OQs, PQs, SOPs and FATs we understand their significance. Validation-ReadyDocumentation: GAMP Compliant Metering Performance and Accuracy Versatility is also evident in the control packages supplied by Schenck Process ֖ volumetric or gravimetric, batch or continuous.For weight-based continuous...

Abrir o catálogo na página 6

Return on investment (ROI) is an importantconsideration when selecting capital equipment. Given the unique R&D, pilot production, ramp-up and validation costs associated with pharmaceutical and nutraceutical manufacturing, in no other industries is ROI more important. That is why our focus has been on maximising your ROI by supplying high quality, high performance and versatile dry solids metering equipment that is easy to install and performs flawlessly for years. For ROI and the lowest cost of ownership in the industry, Schenck Process is your best choice. Customised to meet your...

Abrir o catálogo na página 7

ή Volumetric Feeders Gravimetric Feeders MC 3-A-S Feeder In-line Vibratory Feeders Compact, flexible and easy tointegrate. Already proven more than 30,000 times overas a cost-effective solution. The modular dosing systemfor a wide range of dry bulk solids, with integrated measurement, control and regulation electronics. USDA/3-A accepted feeder forvolumetric and gravimetric applications with integrated measuring and control electronics. Quick and easy dismantling for cleaning and product change. Volumetric and gravimetricdosing of the latest design.For sensitive materials that must not be...

Abrir o catálogo na página 8

When accuracy counts. Count on Schenck Process. You have the optimum recipe we have the right weighing and feeding solution for even your most complex tasks.The combination of know-how, field proven technology and many years ofexperience enables Schenck Process to offer customers within the pharmaceutical and nutraceutical industries tailor-made solutions in a hygienic design.In continuous production systems, the additives are frequently fed to a mixer,kneader or extruder using the gravimetric dosing process. This requires both high dosing accuracy and consistency.In discontinuous operating...

Abrir o catálogo na página 9Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

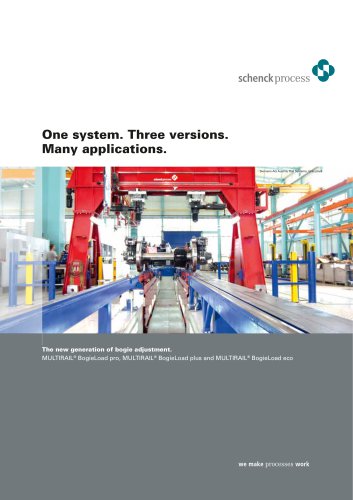

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas