Excertos do catálogo

Paving the way for increased safety. MULTIRAIL® Technology. Measuring, checking, monitoring and sand filling.

Abrir o catálogo na página 1

A sign of our times: more and more people and materials need to reach their destinations faster than ever before. Schenck Process MULTIRAIL® helps you do just that.

Abrir o catálogo na página 2

As our world becomes ever more interconnected, we increasingly need to be mobile and to transport goods. As the world population grows, we need more and more affordable and safe means of transport. Mine owners and production companies the world over are competing for transport corridors planned to the minute in a limited rail network with ever longer and ever heavier trains. Individual transport by car and plane have long reached the limits of their capacity and economic viability in many places. New high-speed routes and underground systems are therefore being planned or already being...

Abrir o catálogo na página 3

Weighing liquids during travel? Because we know that time’s money, we’ve simplified things. With MULTIRAIL® LiquidWeight. And what’s more, for 100 ton wagons travelling at a speed of 3 – 7 km/h, the deviation is just ± 200 kg.

Abrir o catálogo na página 4

Time’s money – especially when loading precious liquids into tank wagons. When they leave the factory, they need to be weighed in a highly accurate and legal-for-trade manner. We are finally seeing an end to the practice of trains having to remain stationary until the liquid is no longer swashing around and the wagons having to be accurately parked on the scales and decoupled. With MULTIRAIL® LiquidWeight, the train set can be easily weighed while travelling at a slow speed without the need to stop. The legal-for-trade weights of all wagons automatically appear on the operator’s screen...

Abrir o catálogo na página 5

Wheel diagnosis at 250 km/h! Essential as we don’t leave safety to chance.

Abrir o catálogo na página 6

Rail track operators want to know the weight of trains travelling on their track, and the owners of rail vehicles need to know if their trains are running unevenly. Such information is crucial to optimised maintenance intervals and rail transport safety, as heavily overloaded wagons or a wheel flat caused by a brake defect bring with them huge potential for derailment, that needs to be detected and corrected in good time. Optimised travel also improves comfort levels and reduces noise. The MULTIRAIL® WheelScan and MULTIRAIL® InterScan dynamic force measuring devices additionally calculate...

Abrir o catálogo na página 7

Zero tolerance to loading mistakes! We know that accuracy is paramount here, often more so than in other situations.

Abrir o catálogo na página 8

When mine operators in Australia need to load train sets with 5 locomotives, 234 wagons and a length of almost 3 km for transport to the port, each wagon has to be precisely loaded – not too light and not too heavy. MULTIRAIL® TrainLoadOut plays a decisive role in achieving this optimum with high levels of reproducibility regardless of the weather and product characteristics. We automatically weigh each wagon before and after loading and can immediately optimise its load depending on the results. This also benefits the port, which can fully rely on the incoming train set, accurately loaded...

Abrir o catálogo na página 9

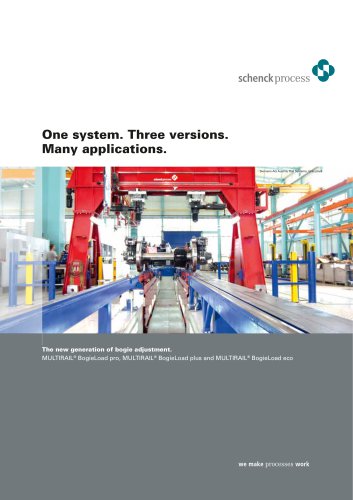

Siemens AG Austria, Rail Systems, Graz plant If you start with nothing, you end up with nothing. Quiet, comfortable and low-wear rolling stock is the result of hard work in vehicle construction and in the maintenance workshop – and our hard work too. Siemens AG Austria, Rail Systems, Graz plant

Abrir o catálogo na página 10

Precision is needed in the workshops to ensure that trains can run quickly and safely with minimum wear. Here bogies and rail car bodies are measured, adjusted and thereby optimised under simulated load conditions, both when originally built and when undergoing maintenance. Schenck Process of course handles all the major technical work involved in measuring force and geometry. From adjusting the bogies with MULTIRAIL® BogieLoad and adjusting the rail car bodies with MULTIRAIL® CornerLoad to final checks on the distribution of load after assembly with MULTIRAIL® WheelLoad, we provide all the...

Abrir o catálogo na página 11

Sand filling. Some may say it’s old-fashioned, others that it’s tried and tested. We would add that it’s indispensable. Even today, all kinds of trains everywhere carry sand. In critical situations, it is spread in front of the driven wheels to increase traction, for example for safer braking. Now that we have integrated Clyde Process within the Schenck Process Group, we can offer rail workshops complete solutions in this area with MULTIRAIL® SandPiper – as mobile or stationary systems.

Abrir o catálogo na página 12

Schenck Process MULTIRAIL® rail products. Our drive, and what is behind it. Schenck Process has developed special load cells for different, highprecision industrial applications. Virtually all the weighing technology solutions of the MULTIRAIL® family are based on well-engineered and virtually invisible force measuring technology integrated in the sleepers which stably transfer forces in the track and at the same time precisely calculate the vertical and sometimes horizontal wheel forces. Our expertise in this area allows us to collaborate with virtually all major European rolling stock...

Abrir o catálogo na página 13

Schenck Process Group – your global partner Acting locally to support your needs, you will find the Schenck Process Group wherever you are. With a global network of sites and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for industrial weighing, conveying, feeding, screening, automation and air filtration technology. Our key competencies include planning processes, feeding bulk materials, controlling flows of material, recording flows of goods, weighing goods and automating transport processes....

Abrir o catálogo na página 14

Looking for solutions? Our comprehensive Process Advanced Service System (PASS) offers customer-focussed after-sales service to meet your individual needs. The structure of our PASS programme is tailored to our customers. Our experienced after-sales team will be happy to produce PASS packages to suit your needs. They may include genuine replacement parts, wearing parts, various services and other high-quality components. PASS is based on a modular principle. You choose individual PASS products or a combination thereof as required. The products are classified in four categories to make it...

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas