Excertos do catálogo

Bulk Materials Handling We've listened and designed them for you...

Abrir o catálogo na página 1

Introduction Schenck Process Group, are leading providers of feeding, automation and bulk solids handling solutions. With a global network of sites and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for industrial weighing, feeding, conveying, screening, automation and air filtration technology. Our philosophy is based on... O Continuous product development O Best practice approach to applications O Raising industry standards Capabilities O Single machine O Multiple machines O System solutions O...

Abrir o catálogo na página 2

The CE4000 The CE4000 range of en masse conveyors has been developed as part of our policy of continuous improvement and a best practice approach to all aspects of our work in bulk materials handling. This new generation of Schenck Process chain conveyors directly reflect customers' needs for a machine that operates reliably in demanding environments without risk to the high efficiencies that modern production requires. Designed with ease of inspection in mind the CE4000 range allows prompt and preventative maintenance to be undertaken with the absolute minimum of plant disruption and...

Abrir o catálogo na página 3

we make processes work High Strength Chain - Alternative Q Engineered chain ® Versatile welded steel design ® Riveted construction $ High tensile strength ® Welded flight attachments Q Extensive flight range available Driving End $ Fully bolted segmented drive sprocket assembly for rapid replacement $ Multi directional sprocket shaft removal $ Heavy duty robust sprocket stripper Q Positive landing for pedestal bearing mountings facilitating easy change out Tension End $ Fully bolted segmented trailing wheel assembly for rapid change out $ Unique profiled trailing wheel for positive chain...

Abrir o catálogo na página 4

Chain Type Key Design Elements ^ Best practice approach throughout $ Design driven by industry users $ Constructed to aid preventative maintenance ^ Component condition monitoring $ Produced for rapid inspection & diagnosis $ Easy replacement of wear components ^ Chain tension system $ Lifetime alignment visibility ® Heavy duty & dust tight construction $ Condition monitoring $ Bolted wearstrips & return runner supports ® Weatherproof 'Viewports' at each casing joint enabling quick inspection for wear and runner alignment Q Laser profiled end flanges to connect Quickview ® Unique...

Abrir o catálogo na página 5

Protection System $ Schenck Process RoCon detects abnormal conditions in drive systems & stops machines rapidly $ Schenck Process Auto Grease automatically dispenses controlled & continuous lubrication to the bearings ® Schenck Process service / inspection visit on each machine application

Abrir o catálogo na página 6

Alternative Fuels Bio Fuels Cement Cereal Processing Coal Chemical Food Grain Mineral Particle Board Ports & Terminals Power Recycling Steel Waste Water Treatment

Abrir o catálogo na página 7

08.13 All information is given without obligation. All specifications are subject to change. BV-P 9004 GB Schenck Process is the global market leader of solutions in measuring and process technologies in industrial weighing, feeding, conveying, screening, automation and air filtration technology. Schenck Process develops, manufactures and markets a full range of solutions, products and turnkey systems on the basis of combining process engineering expertise, reliable components and field-proven technology. Schenck Process UK Limited Carolina Court, Lakeside Doncaster, DN4 5RA United Kingdom...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

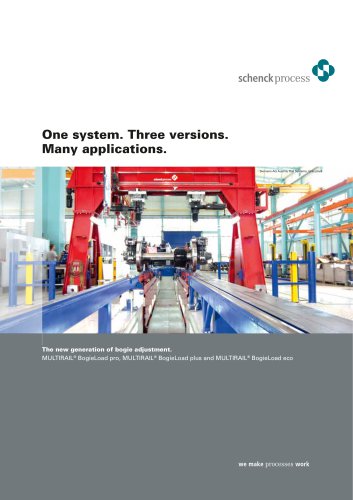

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas