MechaTron® The Modular Feed System With Integrated Measuring, Control, and Supervisory Electronics

1 /

8Páginas

Excertos do catálogo

MechaTron® – Simply Well-Fed. of making processes work MechaTron® – The Modular Feed System With Integrated Measuring, Control, and Supervisory Electronics we make processes work

Abrir o catálogo na página 1

MechaTron® The feed system for any bulk solid

Abrir o catálogo na página 2

Looking for a partner for planning and realizing your feed system? The answer is: Schenck Process – a company that has made a name for itself by designing and supplying state-of-the-art weighing, feeding, and screening systems. With our MechaTron® feed system, we are successfully represented in the marketplace. The MechaTron® is designed to feed bulk solids of all kinds, e.g. powders, granules, pellets, chips, and fibers. Volumetric or gravimetric – thanks to its modular construction and versatile combinations, all types of feed applications can be realized in the feed rate range from 0.2...

Abrir o catálogo na página 3

MechaTron® Series Choose as you please. Depending on the feed rate, you can select 4 different series for the ranges from 0.2 dm3/hr to 32 m3/hr for use in volumetric and gravimetric applications either as Coni-Flex® or Coni-Steel® variant. Small Range: Feed rates min./max.: 0.2 to 22 dm3/hr Low Range: Feed rates min./max.: 0.4 to 1,500 dm3/hr Mid Range: Feed rates min./max.: 4 to 10,000 dm3/hr High Range: Feed rates min./max.: 36 to 32,000 dm3/hr

Abrir o catálogo na página 4

We are testing for you! Difficult-to-feed materials or new applications? Upon request, we will test your bulk solids in our test field, for you to be sure that our feed systems operate perfectly. Put our science to work for you. Evaluation electronics and control in the Schenck Process test field. The Right Discharge Unit For Any Material The MechaTron® offers the right discharge unit for any feed duty. Single and twin screws as well as vibro feeders are available. Single discharge units are used for freeflowing to slightly sluggish materials. Thanks to the simple and rugged design of...

Abrir o catálogo na página 5

Quick and Easy Material Change. The MechaTron® enables the contact parts to be removed and mounted from the non-process side for material change and cleaning, thus minimizing downtimes and reducing operating costs. Removing screw Swivelling motor MechaTron® – Coni-Flex® The discharge unit motor assembly can be swivelled around an axle located parallel to the feed screw. When the motor is swivelled out of its operating position, discharge unit, shaft sealing and feed hopper can be accessed with utmost ease. A single operator can remove feed screw and hopper with few movements. Removing feed...

Abrir o catálogo na página 6

MechaTron® – Electronics Integrated. Swivelling motor With the MechaTron® feed systems, the electronics including the DISOCONT® measuring and control system are incorporated into the mechanical system. MechaTron® – Coni-Steel® The vertical agitator is split. The feed hopper can easily be removed with no need to dismount the complete agitation system. So the system leaves scope for individual planning since the precious headroom can be optimally used. Small size Reduced cabling Lower prime costs Easy servicing Electronics and mechanics form a unit and can easily be integrated into the...

Abrir o catálogo na página 7

4000.11.06 di • All information is given without obligation. All specifications are subject to change. Schenck Process is the global market leader of solutions in measuring and process technologies in industrial weighing, feeding, measuring and automation. Schenck Process develops, manufactures and markets a full range of solutions, products and turnkey systems on the basis of combining process engineering expertise, reliable components and field-proven technology. Schenck Process GmbH Pallaswiesenstr. 100 64293 Darmstadt, Germany T +49 61 51-32 11 19 light@schenckprocess.com...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

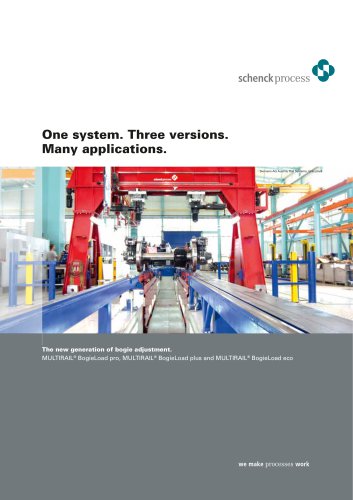

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas