Excertos do catálogo

LinaClass® screens – They run. And they run. And ... Schenck Process – Experts in vibratory equipmen

Abrir o catálogo na página 1

Our solutions Schenck Process LinaClass® screens fulfil all these requirements perfectly. They can handle the largest quantities of materials and classify them to a high level of accuracy. Driven by robust DF force exciters, they are specially adapted to the widest range of requirements. Benefits Ease of maintenance, long working life, maximum availability, reliable and consistent quality. Schenck Process is synonymous with dynamically developing and manufacturing vibratory equipment. Around 90 years of experience, superlative quality, outstanding technology and an extensive customer...

Abrir o catálogo na página 2

LinaClass® linear vibrating screens The classic version for the classification of all bulk solids suitable for screening. All common screen panels can be used. LinaClass® SLG Single-deck linear vibrating screens LinaClass® SLX Single-deck linear vibrating screens LinaClass® SLK Double-deck linear vibrating screens LinaClass® banana screens This machine takes its name from the banana-like arrangement of the screen panels. This enables the screening of larger quantities of material with a high content of fine particles. The advantage in comparison to the conventional screening machine: a much...

Abrir o catálogo na página 3

HuckBolted construction Over 1000 HuckBolts® in the sideplates but no welds, the sideplate has no residual welding stress and no material discontinuities to compromise the fatigue strength of the machine. This important feature contributes to the exceptionally long service life typical of Schenck Process machines. Economical, smooth running The Directional Force Exciter ranges from Schenck Process make the ideal drivers for linear motion vibrating screens. Oil lubrication and optimised roller bearing and gear pairing ensure smooth running, longer exciter working life, resulting in...

Abrir o catálogo na página 4

Maintenance-free Maintenance-free shafts between exciters mean more production and less downtime. Tuned for optimum productivity Schenck Process drive systems are designed to allow us to tune the run speed of your machine for optimum performance. Thicker deck rails Schenck Process machines are designed to carry the weight of ultra heavy duty deck media with extra high sideliners. This means longer service life, less maintenance and a lower production cost per tonne. Screen panels In order to perfectly adapt screening machines to individual challenges, Schenck Process has developed the...

Abrir o catálogo na página 5

schenckprocess The Schenck Process Group is a global leader in weighing and feeding technology III screening and separation systems for bulk materials III dust collection and air filtration technology III pneumatic and mechanical conveying solutions III automation and diagnostic technology we make processes work © Schenck Process GmbH, 2014 BV-P 2120 GB 250.09-14 dik AI1 informati°n is given without °bligation.

Abrir o catálogo na página 6Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

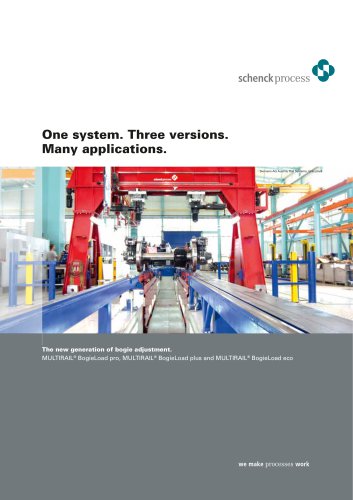

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas