Excertos do catálogo

IDMS 50/100 Blow-Through Rotary Valve for Alternative Fuels .. In-line feeding of non-homogeneous alternative fuels into pneumatic conveying systems .. Compact, space saving, blow through design for feeding cohesive alternative fuels .. High degree of filling through large inlet section .. Robust cutting blades for reliable size reduction of oversize material .. High abrasion resistant wear parts all exchangeable from the plant side .. Conveying pressure of up to 300 mbar .. Volumetric feed rate up to 150 m3/hr Application The IDMS Blow-Through Rotary Valve has been especially designed and developed for the in-line feeding of non-homogeneous alternative fuels into pneumatic conveying systems within the Cement, Lime, Gypsum and Power industries. Robust in design and performance the IDMS is capable of feeding a wide range of alternative fuels including shredded plastics, foil chips, conditioned sewage sludge, wood chips & saw meal, shredded tyres, palm kernel shells, rice husk, animal meal and various mixed combinations. Design A robust, compact, space saving design ensures high efficiency performance. Durable and reliable air-sealed bearings protect the units. Wear parts thus ensuring optimal and stable pneumatic conveying conditions with minimal air leakage. The valve is characterised by its design: - High degree of filling through its large inlet section - Integral horizontal conveying channel to ensure maximum material ‘pick-up’ velocity directly into the pneumatic conveying line - Robust integral scrapper designed to prevent blocking of the inlet section - Durable and robust cutting blades for the reliable size reduction of oversize material - Directly mounted geared motor - Air-sealed bearings Operation The IDMS Blow-Through Rotary Valve is used as a feeding device to directly feed of non-homogeneous alternative fuels into pneumatic conveying lines at conveying pressures of up to 300 mbar. Typically, a pre-feed device positioned between the upstream material silo is used to consistently feed the material into the IDMS. The integral scrapper and cutting blades are designed to prevent the IDMS from becoming blocked with foreign bodies or oversized particles. For ease of use and maintenance, the high abrasion resistant wear parts are all exchangeable from the plant side without the need to completely disassemble the unit. The geometry of the unit’s inlet, chambers, conveying channel and outlet guarantee efficient material flow into the pneumatic conveying line thus a high material conveying to air ratio is achieved. BV-D2243GB

Abrir o catálogo na página 1

Technical Data Model A B C D E F G H IDMS 50 450 800 1050 2000 800 85 DN125 225 IDMS 100/90 DN150 IDMS 100 800 820 1600 2400 1300 - DN200 350 Model IDMS 50 IDMS 100/90 IDMS 100 Feed rate [m³/hr] 50 100 150 Feed rate [t/hr with bulk material densities of 0.1t/m³] 5 10 15 Possible particle sizes, 3D, 97% < [mm] 30 60 60 Max. particle size, 2D, 1-3% [mm] 50 100 100 Rated speed [m-1] 19 15 15 Number of chambers 10 12 12 Max. leakage air [Nm³ at 300 mbar back pressure] 400 600 600 Purge air supply for the shaft seal [Nm³/hr] 56 100 *1) 80 *1) Material: - Starwheel Mild steel - Housing wear...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

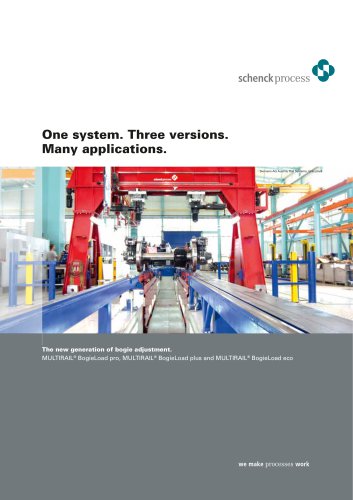

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas