Excertos do catálogo

feeding systems, basic plastic powders(e.g., PE, PP) and additives (carbon black, titanium dioxide,etc.) are fed into the extruder directly or via a continuous mixer by means of the MechaTron The proven DISOCONT > ή measuring and controlelectronics permit easy integration in the production process.The powder is plasticized in the extruder under highpressure and high temperature and modified in a physical mixing process. The granulator at the extruder discharge cuts the plastic strand into granular form with remarkableperformance. Large granular plants operate at a feed rateof up to 40 t/h...

Abrir o catálogo na página 2

Day bin ExtruderQuenching bathGranulatorLiquid feedingMULTIGRAV MechaTron ή L Material may be fed into the compounder invarious ways: Other standard plastic materials Vertically by means of an inlet funnel Fillers (e.g. CaCO > 3 , talc, carbon black) Horizontally via a lateral feeder, which conveys into the melt Free to poor flowing additives perfectly fed > ֮ Fibers (glass fibers, coal fibers) MechaTron Loss-in-Weight Feeders provide the optimalfeeding component for any application desired. From single-shaft and double-shaft feeding components to vibratory feed trays. Other additives...

Abrir o catálogo na página 3

PTA and IPA powders as well as glycol are fed into a pastevessel and processed into polyester, in the downstream polycondensation. Customized for Your Application PTA feeding system using the MULTICOR > S mass flowmeasuring device and feeding screws or star feederswith speed regulation Glycol feeding using volumetric feeding pumps IPA feeding using MechaTron > ή Loss-in-Weight Feederswith single feeding helix and paddle discharge aid. Refill systems for Loss-in-Weight Feeders with butterfly valves and silo discharge aids. The proven DISOCONT > measuring and controlelectronics permit easy...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

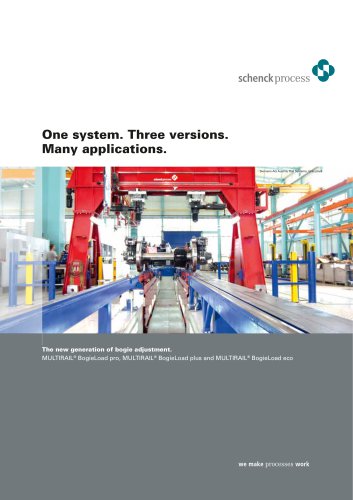

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Award Winning Solutions

6 Páginas