Excertos do catálogo

Enduro isolation springs Safe and reliable, even in the most arduous environmental conditions.

Abrir o catálogo na página 1

Excellence in safety Enduro isolation springs Enduro springs are specially designed steel coil springs fully encapsulated in rubber. Apart from the obvious safety advantages, eighty percent of the spring effect is ascribed to the high carrying capacity steel coils whilst the rubber provides protection of steel coils from corrosion and other detrimental environmental effects. Enduro springs present excellent safety, operational, functional, and economical advantages over commonly used spring types such as steel springs, solid rubber buffers, and other types of steel-rubber combinations. In...

Abrir o catálogo na página 2

Consists of a steel spring core with a high carrying capacity, covered with hot-vulcanized rubber Enhanced safety features Design completely eliminates pinch points Inherent shock absorber effect dramatically reduces screen jumping during start-up and shut-down Significantly reduces noise levels Less downtime resulting from considerably longer lifespan, often in excess of six times that of typical steel springs Designed to effectively isolate machine motion from the stationary support structure Can be used in corrosive environments Rubber sheath protects material from getting caught between...

Abrir o catálogo na página 3

08.15 di · All information is given without obligation. All specifications are subject to change. BV-P 2136 EN Schenck Process GmbH Pallaswiesenstr. 100 64293 Darmstadt, Germany T +49 61 51-15 31 10 00 vibrating@schenckprocess.com www.schenckprocess.com © Schenck Process GmbH, 2015 The Schenck Process Group is a global leader in weighing and feeding technology /// screening and separation systems for bulk materials /// dust collection and air filtration technology /// pneumatic and mechanical conveying solutions /// automation and diagnostic technology

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

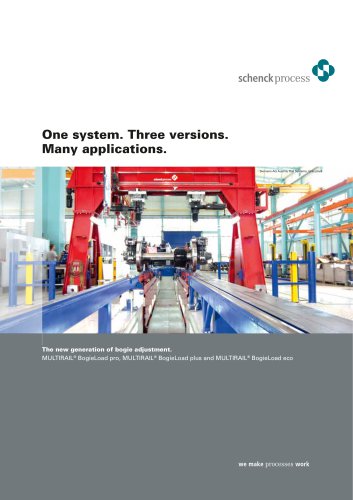

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

DISOCONT ®

4 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas