Excertos do catálogo

DISOCONT® Measurement, Control and Supervisory System % Field housing electronics integration able into scale mechanics % New product line for ‘MechaTronic scales’ a synthesis of mechanics, electrics and software % Reduced engineering planning and wiring costs % Optimal communication structures because of modular fieldbus technology Application DISOCONT® is a modular electronics system applicable to any weighing and feeding system. It is used wherever bulk solids flow has to be measured, feeded or batched with the use of % Loss-in-weight feeders (measur-ing/feeding) % Weighfeeders % Mass flow meters and feeders % Solids flow meters and feeders % Belt weighers % Weighing hoppers The DISOCONT® electronics are prefer-rably integrated locally into the scale mechanics. So self-contained function units will be created - the MechaTronic scales - which offers numerous advan-tages: % Reduced engineering because of minimal number of interfaces; only one unit has to be planned in % No control cubicle % Reduced cabling; only power and data cables have to be run % At a glance - easy service because of the combination of mechanics and electronics DISOCONT® electronics may be conven-tionally installed in a control cubicle (e.g. for use with feeders in hazardous zones). The DISOCONT® equipped with appro-priate communication module optimally integrates into the automation structure via field bus. Equipment The DISOCONT® electronics consist of a system unit and multiple optional expan-sion units. Its modular design enables the requisite units to be combined for a spe-cific application, at a most cost effective price. % System unit for all measuring and control functions; equipped with service plug for connection of laptop or control unit, for configuration, calibration and service with an exchangeable memory module for system specific settings and operat-ing values % Fieldbus communication modules plugged into system unit for transfer of all relevant data to the user’s control and scale control system % Input/output unit for conventional connection to user’s control system and expanded control of the scale environment % EasyServe - PC-program for commissioning and service % Operator panel with clear graphic text display for local scale control and/or parametrization of standard applications. % Group control unit- operation, survey and control of scale groups, as shown in separate spec sheet The internal DISOCONT® communication bus permits a flexible arrangement of the I/O units, locally or in cabinets. All modules can be replaced with no need for recalibration and reconfiguration (Plug & Play). The program includes housing options for installation at site and in control cubicles. BV-D2051GB

Abrir o catálogo na página 1

Technical features for all weigh-ing and feeding systems: % System accuracy for scales better than 0,05% (DIN 43782) % Galvanically isolated inputs/ outputs % Pluggable, fail-safe memory module % Factory presettings for easy and quick commissioning % Various languages loadable/ transferrable % Status, event, calibration, and batch reports % Batch control with adaptive cut-off curve % Integrated diagnostics and self testing functions (SPC) % Simulation mode for testing and learning Functions DISOCONT® is designed to acquire the actual feed rate [kg/h, t/h] via % belt load and belt speed for...

Abrir o catálogo na página 2

Technical Data DISOCONT® - System Unit VSE 20100 Power supply 24 VDC ± 20 %; 110 V - 230 V -20 % +10 % (50 Hz or 60 Hz); 20 W Ambient temperature -25°C ... +50°C outside housing Inputs*) Load cell input (+/- 6 V, Ri > 87 Ù) 2 NAMUR-Inputs (0,03 - 3000 Hz for speed, belt circuit/gate feedback signal) 2 isolated digital inputs (24 V, 20 mA, safety separated) Outputs*) 1 isolated analog output (0/4 mA ... 20 mA, max. 11 V) 4 relay outputs, safety separated (24 V or 230 V with combinations: 3 x 24 V and 1 x 230 V, or 3 x 230 V and 1 x 24 V; 8 A Ù / 1 A induct.) Interfaces RS 232 (Service PC...

Abrir o catálogo na página 3

DISOCONT®-Control Unit VLB 20120 in Field Housing Material Glass fibre reinforced plastics Dimensions 260 mm x 160 mm x 110 mm Protected to IP 65 (as per IEC 60 529), NEMA4-type Display LCD-graphics display (100 mm x 75 mm) Character height (3,5 mm or 9 mm) Keyboard Flexible membrane keyboard Power supply 24 VDC ± 20%; 110 V - 230 V -20% +10% (50 Hz or 60 Hz); 20 W Ambient temperature -20°C ... +50°C outside housing Interface Internal Disocont-Bus interface Standards CE DISOCONT® - Basic Units System Unit VSE 20100 with power supply Memory Module VSM 20100, VSM 20101, VSM 20102 Field...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos Schenck Process Holding GmbH

-

Smart Dust Collection Solution

12 Páginas

-

Precise feeding solutions

4 Páginas

-

FulFiller ®

8 Páginas

-

MULTIBELT® Belt Weigher

8 Páginas

-

CONiQ® Cloud

1 Páginas

-

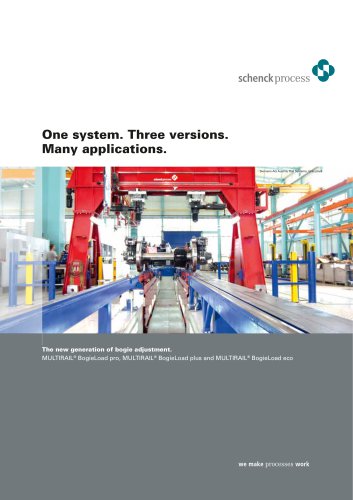

MULTIRAIL® BogieLoad pro

20 Páginas

-

Pharmaceutical industry

10 Páginas

-

MULTIRAIL®

16 Páginas

-

Company overview

20 Páginas

-

Your way to Schenck Process

4 Páginas

-

We make processes work

20 Páginas

-

Material Handling Solutions

8 Páginas

-

Capabilities of Stock

8 Páginas

-

LinaClass® screens

6 Páginas

-

Train loader (TLO) – economic loadin

6 Páginas

-

Screenex® screening media

24 Páginas

-

CONiQ®

12 Páginas

-

Enduro isolation springs

4 Páginas

-

MCPP

12 Páginas

-

ModuPlasma

8 Páginas

-

Airlocks and Diverter Valves

6 Páginas

-

MaxiStore®

8 Páginas

-

SacMaster®

8 Páginas

-

Screen Rebuild Program

4 Páginas

-

Reliability in pet food production

12 Páginas

-

Food industry

20 Páginas

-

MultiTrain® Technology

4 Páginas

-

Training that delivers!

38 Páginas

-

Cement industry

16 Páginas

-

IntraBulk bulk reception unit

8 Páginas

-

MoveMaster® chain conveyors

8 Páginas

-

TEDO Conveyors

18 Páginas

-

ProPulse Industrial Air Filters

12 Páginas

-

Drop forged chain

8 Páginas

-

RoCon® Series 6

8 Páginas

-

Reliable solutions for power generation.

16 Páginas

-

Sustainable Cement Production

10 Páginas

-

Under the harshest conditions

16 Páginas

-

SPro screen panels

12 Páginas

-

LOGiQ® loading automation

10 Páginas

-

Power industries

16 Páginas

-

Tidal Series 5

6 Páginas

-

Screen rebuilding

4 Páginas

-

Weighing Indicator DISOMAT Parvus

4 Páginas

-

RotoScrew

2 Páginas

-

Rotofeed Pneumatic Injector

2 Páginas

-

DWB

4 Páginas

-

MultiFlex

4 Páginas

-

The Original Dome Valve Range

8 Páginas

-

Stock Forry® ESP Products

8 Páginas

-

Stock Coal and Limestone Feed Systems

12 Páginas

-

LinaClass®

6 Páginas

-

FloMaster® Circular Bin Discharger

8 Páginas

-

MoveMaster® Vac Vacuum Conveying Systems

12 Páginas

-

Air pollution control

4 Páginas

-

MULTIRAIL® BogieLoad product family

20 Páginas

-

Stock Valves

8 Páginas

-

IntraBulk - Bulk Reception Unit

8 Páginas

-

Screen panels for the steel industry

6 Páginas

-

MoveMaster CE4000 Chain Conveyors

8 Páginas

-

Bulk Materials Handling Technologies

6 Páginas

-

Product Overview

8 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G - Solid Flow Meter

4 Páginas

-

MULTIDOS® H - Weighfeeder

2 Páginas

-

MULTIDOS® E - Weighfeeder

4 Páginas

-

FulFiller® Container Loading System

6 Páginas

-

SacMaster

1 Páginas

-

MULTIBELT®

1 Páginas

-

MULTIDOS® VDP

1 Páginas

-

Components and Standard Products

206 Páginas

-

INTECONT® PLUS

4 Páginas

Catálogos arquivados

-

We make processes work

16 Páginas

-

MULTIRAIL® WheelLoad

2 Páginas

-

MULTIRAIL® WheelScan

2 Páginas

-

MULTIRAIL® MultiBridge

2 Páginas

-

MULTIRAIL® LiquidWeight

2 Páginas

-

MULTIRAIL® LegalWeight

2 Páginas

-

MULTIDOS® L

4 Páginas

-

MULTIGRAV®

4 Páginas

-

ProFlex® C

2 Páginas

-

Mobile Touch Panel FSB

2 Páginas

-

DISOMAT® Tersus weighing terminal

4 Páginas

-

DISOMAT® Satus

4 Páginas

-

DISOMAT® B plus Ex, Zone 1

4 Páginas

-

INTECONT® Opus

4 Páginas

-

weighing sensor

1 Páginas

-

Rotary Force Exciters

4 Páginas

-

Force exciters

4 Páginas

-

IDMS blow-through rotary valve

2 Páginas

-

MULTISTREAM® G Solids Flow Meter

4 Páginas

-

MULTISTREAM® B

4 Páginas

-

MULTICOR® R 450

4 Páginas

-

MULTIDOS® E

4 Páginas

-

MULTIDOS® M

4 Páginas

-

Accurate Dosing. For Optimum Growth.

6 Páginas

-

Experts in Plastic Production

4 Páginas

-

Award Winning Solutions

6 Páginas