Excertos do catálogo

In FA equipment, motion control using servo systems is a crucial element which greatly affects equipment performance. Naturally, equipment specifications and performance are designed assuming that the expected motion is attained, but if there are factors such as backlash, insufficient rigidity or control instability in the motion control section, then output motion will deviate from input control commands, and it will be difficult to attain the expected performance. With the RollerDrive RE Series, a servomotor is mechanically reduced while maintaining powerful torque, rigidity and...

Abrir o catálogo na página 3

Output shaft Input shaft In order to meet stringent accuracy The shaft is shaped with a large dia- requirements, the alloy steel input meter table surface, and the roller fol- shaft is manufactured using state-of- lowers which transmit rotation are the-art machining theory and equip- provided in a radiating fashion. Rota- ment. Balancing is also done to con- tion is transmitted by the rolling con- trol self-induced oscillation during tact between multiple roller followers high-speed rotation. Roller followers These are roller bearing structures The housing is rigid cast-iron. A hol- which...

Abrir o catálogo na página 4

The RollerDrive reducer is optimally designed for high accuracy reducion. By using a roller gear mechanism, we offer one of the very best motion control mechanisms. The roller gear mechanism consists of main parts such as an input shaft cam (roller gear cam), a cam follower and a turret supporting the cam follower. The cam is screw shaped, and the cam follower displaces the cam relative to the rotation of the cam, thus rotating the turret. The cross-section of the roller gear cam is wedge-shaped and this wedge completely eliminates any backslash taking up the space between the two cam...

Abrir o catálogo na página 5

RollerDrive specifications Permissible output shaft load The RollerDrive RE Series has a built-in Taper roller bearing for output. Please use within a range not exceeding the permissible radial, axial and moment load in the following Table.

Abrir o catálogo na página 6

Drive specifications A servomotor can be mounted to the RollerDrive RE Series. There are two methods of servomotor mounting. Coupling specifications for high-gain are suitable for high-speed precision operation. Timing belt specifications are suitable when drive inertia is large. Motors handled by our company

Abrir o catálogo na página 7

MODEL CODE MODEL CODE • Please write in codes 7 if you want the servo motor provided. • Please write in code 9 if there are special specifications. Please notify us of the content of the special specifications. | Drive specification code (Please discuss with our company) • If a non-standard gear ratio is necessary • If you want to mount another company's servo or a stepping motor instead of a standard

Abrir o catálogo na página 8

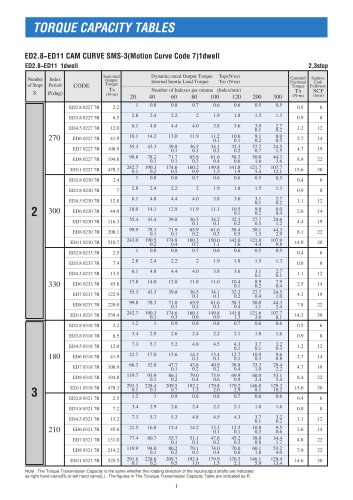

Selection, Capacity check Selection method Loaded torque graph Check torque and rotation speed at start-up, dur- ing steady operation, and at stopping. The average value in the operation interval is used for the rotation speed N. Find conditions Find the average loaded torque from the loaded torque graph. Average output rotation speed Average input rotation speed Maximum input rotation speed mean — "mean nmean><i (Gear ratio) (rpm) ■^max = nmax (Maximum output rotation speed) xi (Gear ratio) (rpm) Selection is completed when the required specifications are met

Abrir o catálogo na página 9

Example of servomotor mounting RE63 Timing belt specifications

Abrir o catálogo na página 10

Example of servomotor mounting RE80 Timing belt specifications Part of the drive section sticks out from the housing and output table surface.

Abrir o catálogo na página 11

Example of servomotor mounting RE100 Timing belt specifications Part of the drive section sticks out from the housing and output table surface. Part of the drive section sticks out from the housing and output table surface.

Abrir o catálogo na página 12

Example of servomotor mounting RE125 Timing belt specifications

Abrir o catálogo na página 13

Example of servomotor mounting RE160 Timing belt specifications

Abrir o catálogo na página 14

Example of servomotor mounting RE250 Timing belt specifications

Abrir o catálogo na página 15

Technical information Technology supporting performance and quality Data backed up by basic development results of Sankyo Selsakusho, and state-of-the-art research results, are provided as feedback to achieve the superior RollerDrive requires high accuracy and special machining, and each unit is manufactured in a plant equipped with special-purpose ultra high-accuracy machining equipment and a clean room for assembly, and then shipped after passing a stringent quality/accuracy inspection. Materials used in the product, production equipment and packaging materials are all designed to enable...

Abrir o catálogo na página 16

Limitations on the use of this product •This product cannot be used in applications where operation of the product has a direct impact in human life, or can cause bodily harm to people. The scope of these use limitations includes the following applications: ii. Nuclear power related equipment iv. Equipment for handling explosive, corrosive or toxic substances etc. •Please consult with our company if you are considering use in one of the above applications. •If there is a possibility that this product will be used in a final use location outside Japan, in weapons or equipment for weapon...

Abrir o catálogo na página 17

Related products The RollerDrive RA Series employs a highly-rigid cross roller bearing with extremely small deflection in the output section. This is a revolutionary motion control unit for FA, and includes innovations such as an aluminum alloy case for greater lightness, and a specially designed method of fastening the motor shaft. RollerDrive RA Series specifications The precision movement and superior dynamic stability of RollerDrive are also a powerful force in the world of machine tools. The RC Series employs a CNC circular table designed to meet the need by machine tool manufacturers...

Abrir o catálogo na página 18

For the latest information, or to download selection SHIZUOKA FACTORY HEAD OFFICE(TOKYO) CHIBA MIYAGI 37-3,3-chome Tabatashinmachi Kita-ku Tokyo Japan 114-8538 E-mail: overseas@sankyo-seisakusho.co.jp P.O.Box 433810655 State Route 47, Sidney, Ohio, 45365 U.S.A. E-mail: sales@sankyoamerica.com 1NA 304, SHIHWA INDUSTRY COMPLEX 1242-4H0, JEONGWANG-DONG, SHIHUNG-CITY, KYUNGGI-DO, KOREA E-mail: sankyo@sankyokorea.co.kr HANGZHOU SANKYO MACHINERY CO., LTD. N0.8 DA Dl ROAD, XIAO SHAN ECONOMIC AND TECHNOLOGY DEVELOPMENT ZONE, HANGZHOU ZHE JIANG 311215 CHINA E-mail: sales@sankyochina.com SANKYO CHINA...

Abrir o catálogo na página 19Todos os catálogos e folhetos técnicos SANKYO

-

RCC Series

8 Páginas

-

RW series

8 Páginas

-

SPC Series

2 Páginas

-

TCU Series

2 Páginas

-

RSD Series

1 Páginas

-

EX Series

1 Páginas

-

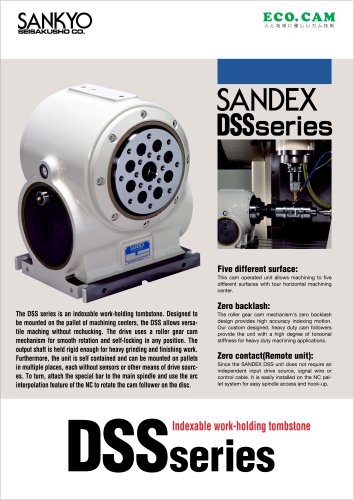

DSS Series

1 Páginas

-

DST Series

1 Páginas

-

VS-s Series

2 Páginas

-

CNC Series

16 Páginas

-

ECO Series

32 Páginas

-

α (Alpha) Series

44 Páginas

-

Large RU Series

24 Páginas

-

RU Series

28 Páginas

-

Long stroke linear drive unit

6 Páginas

-

Precision adjustable feed Variax

12 Páginas

-

SANDEX

8 Páginas

-

RollerDrive

28 Páginas

-

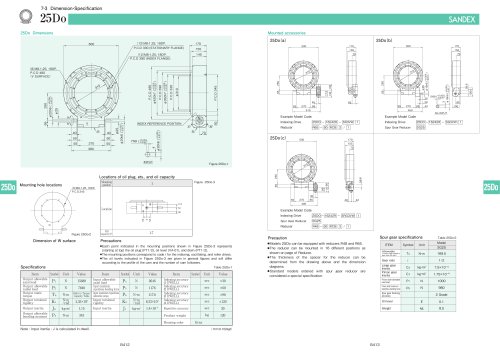

Do series

7 Páginas

-

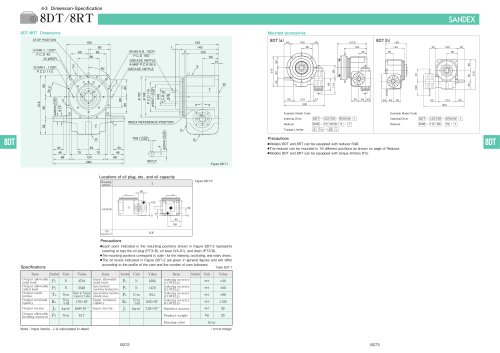

DT, DTR series

11 Páginas

-

RY series

16 Páginas

-

RA series

32 Páginas