Excertos do catálogo

ENERGY-ISOLATION & EEZ-ON® PRODUCTS L-O-X® Valves • EEZ-ON® Valves L-O-X® Valves with EEZ-ON® Operation • Manufacturers of Premium Pneumatic Controls since 1921 •

Abrir o catálogo na página 1

Regulations for Workplace Safety The Occupational Safety and Health Administration (OSHA) regulation (29 CFR 1910.147) details safety requirements for the control of hazardous energy during the maintenance and servicing of machines and equipment. WHAT DOES THE RULE REQUIRE? In general terms, the rule requires that energy sources (pneumatic, electric, hydraulic, etc.) be shut off or disconnected while equipment is being serviced. Furthermore, the disconnected valve or switch must be locked to prevent reactivation while anyone is working on the equipment. In the case of air-operated...

Abrir o catálogo na página 2

How Users of Pneumatic Equipment Can Comply with OSHA Rules Here’s how our famous L-O-X® valve helps... ROSS EEZ-ON® Valves Also Add to Plant Safety A ROSS EEZ-ON® valve is designed to allow a gradual buildup of downstream air pressure before opening the line to full air flow. This gradual pressure buildup allows cylinders and other work elements to move slowly and more safely into their normal working positions before full line pressure buildup is applied. The time required for full pressure buildup is adjustable. EEZ-ON® valves are available as either 2/2 (2-port, 2-position) or 3/2...

Abrir o catálogo na página 3

Series 15 L-O-X® Valves with EEZ-ON® Operation Combines L-O-X® Shut-off with EEZ-ON® Gradual Starts VALVE OPERATION The L-O-X® with EEZ-ON® operation valve combines shut-off certainty with gradual pressurization upon start-up. Special labels and adjustment screw indicates EEZ-ON® function. Combining two functions critical to safety concerns in any application, the ROSS L-O-X® valve with EEZ-ON® operation provides the shutdown and the gradual start-up (or, “soft start”) capabilities today’s systems require. In addition, because the L-O-X® valve with EEZ-ON® operation is two units in one, you...

Abrir o catálogo na página 4

Series 15 Manual L-O-X® Valves • Reliable, Low-Cost Control • 1/4 to 3/8 Ports 2 VALVE OPERATION VALVE CLOSED When the red handle is pushed inward, the flow of supply air is blocked and downstream air is exhausted via the exhaust port. While servicing or maintaining machinery, the L-O-X® valve should be padlocked in this position to prevent the handle from being pulled outward inadvertently where potential for human injury exists. Manual L-O-X® valve shown padlocked in closed position. The valve can only be locked in the closed position. Push/pull operation - Push the handle inward to...

Abrir o catálogo na página 5

Series 15 Manual L-O-X® Valves • Reliable, Low-Cost Control • 3/8 to 11/4 Ports VALVE OPERATION VALVE CLOSED With a short push of the red handle inward, the flow of supply air is blocked and downstream air is exhausted via the exhaust port at the bottom of the valve. The L-O-X® valve should be padlocked in this position to prevent the handle from being pulled outward inadvertently where potential for human injury exists or while servicing machinery. Manual L-O-X® valve shown padlocked in closed position. The valve can only be locked in the closed position. The position of the red handle...

Abrir o catálogo na página 6

Series 15 Manual L-O-X® Valves 2 • Reliable, Low-Cost Control • 11/2 and 2 Ports Manual L-O-X® valve shown padlocked in closed position. The valve can only be locked in the closed position. Push/pull operation - Push the handle inward to exhaust downstream air (lockable in this position). Pull the handle outward in to supply air downstream. 11/2 and 2 The ROSS LOX® 1-1/2 and 2 inch port size are the newest addition to ROSS’ renowned family of safety-related products. Following any FRL components, an energy isolation valve is usually the first valve in the line supplying compressed air to...

Abrir o catálogo na página 7

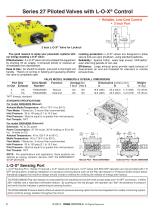

Series 27 Piloted Valves with L-O-X® Control • Reliable, Low-Cost Control • 3 Inch Port 3 Inch L-O-X® Valve for Lockout Five good reasons to equip your pneumatic systems with our energy isolating L-O-X® valve: Effectiveness: A L-O-X® valve not only isolates the equipment by shutting off air supply, it exhausts stored or residual air immediately from downstream. Ease of Use: Air shutoff is simple; just push in the bright red handle. There’s no turning or twisting and guessing whether the valve is completely open. Port Size In-Out Exhaust Locking protection: L-O-X® valves are designed to...

Abrir o catálogo na página 8

Series 27 Manual Piloted Valves with L-O-X® Control Port Sizes up to 21/2 for Larger Systems VALVE OPERATION Y3 2 3 Operated just like the smaller manual L-O-X® valves shown on page 5. The position of the red handle indicates instantaneous full flow pressurizing or exhausting capability. Following any FRL components, an energy isolation valve is usually the first valve in the line supplying compressed air to equipment. The energy isolation valve should provide a quick means of shutting off the supply of air and exhausting the downstream lines. The ROSS manual pilot L-O-X® valve has a large...

Abrir o catálogo na página 9

Series 27 Solenoid Piloted Valves with L-O-X® Control Remote Control in a Full Range of Valve Sizes 3 VALVE OPERATION The position of the red handle indicates instantaneous full flow pressurizing or exhausting capability. Following any FRL components, an energy isolation valve is usually the first valve in the line supplying compressed air to equipment. The energy isolation valve should provide a quick means of shutting off the supply of air and exhausting the downstream lines. The shut-off function of the solenoid pilot controlled L-O-X® valve is the same as that of the manual L-O-X®...

Abrir o catálogo na página 10

Series 27 EEZ-ON® Valves A Gradual Start-up for Pneumatic Circuits 2/2 EEZ-ON® Valves VALVE OPERATION ADJUSTING NEEDLE AIR PRESSURE TO INLET When air pressure is first applied to the inlet, air flow to the piston is restricted by the adjustable needle in the delay orifice. Downstream air pressure gradually builds up at a rate determined by the setting of the adjustable needle. The EEZ-ON® valve is designed to allow a gradual buildup of downstream air pressure before opening to full air flow. This gradual pressure buildup allows cylinders and other work elements to move slowly and more...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos ROSS Controls

-

safety product

32 Páginas

-

ISO Valves and Serial Bus Communication

56 Páginas

-

Line-Mount Valves

16 Páginas

-

DM2

4 Páginas

-

MD3

16 Páginas

-

CM series

4 Páginas

-

Press Industry Solutions

28 Páginas

-

DM2 Series D

16 Páginas

-

filters, regulators and lubricators

84 Páginas

-

Safety-Related Products

32 Páginas

-

Fluid Power Safety Overview

4 Páginas

-

Modular Pneumatic Solutions

8 Páginas

-

Electro-Pneumatic Proportional Valve

2 Páginas

-

Drip Leg Drains

2 Páginas

-

Dale Series Poppet Valves and Manifolds

28 Páginas

-

ISO 5599 I and II VDMA 24563

20 Páginas

-

Series 80 and 84 SAE Std

12 Páginas

-

Series 70 and 74

12 Páginas

-

L -O-X ® V a l v es

4 Páginas

-

W60

4 Páginas

-

foot valves

1 Páginas

-

manual valve

12 Páginas

-

Pilot operated check valves

12 Páginas

-

safety valve

13 Páginas

-

FRL ROSS

12 Páginas

-

poppet valve

16 Páginas

-

TSSA

48 Páginas

Catálogos arquivados

-

ENERGYSAVER® Valve

2 Páginas

-

Ross regulators

2 Páginas

-

serial bus system

29 Páginas

-

Dale series poppet valves

16 Páginas