RIGCHINA- SAND CONTANT KIT | RSCT-200 | preferred method for sand content determination because of the reliability of the test and simplicity of equipment

1 /

4Páginas

Excertos do catálogo

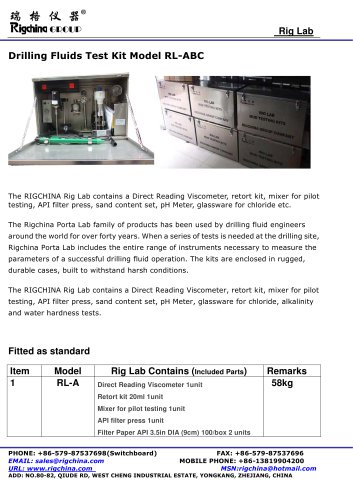

RSCT-200 SAND CONTANT KIT Instruction Manual Quality is Everything... Telephone: 86-579-87537698, 86-13819904200 Fax : 86-579-8753 696 Rev.B Website: http://www.rigchina.com, Email: sales@rigchina.com MSN:rigchina@hotmail.com Address: No.80-82, Qiude Road, West Cheng Industrial Estate, Yongkang city Zhejiang Province, China

Abrir o catálogo na página 1

1. Summary This is a simple and reliable apparatus for measuring sand content of drilling fluids effectively and accurately. The method that screen decomposes is used to decide the content of sand. The sand content of drilling fluids is defined as the percent ratio of the volume of sand which can not pass through the screen mesh No. 200, i.e., whose diameter is larger than 0.074 mm, to the volume of the drilling fluid. 2. The main technical parameters of apparatus The major technical parameters of the instrument are listed in the following table. Item Name Technical specification hole size...

Abrir o catálogo na página 2

mesh stainless-steel screen with the hole diameter of 0.074 mm in the middle of the filtration tube. The Glass graduated cylinder is a testing cylinder made of glass with the mark of 30ml which is the volume of drilling fluid sample. The percent content of sand can be read out directly because the graduation lines ranged from 0 to 20% are marked on this glass graduated cylinder. The parts of the instrument are listed in the following table: Item Model number lower filtration tube upper filtration tube plastic funnel glass graduated cylinder 5. Operations of the Instrument (1) Fall over a...

Abrir o catálogo na página 3

Fig. 2 The operation diagram (4) Read out the value of the volume of sand and insert the value to the following equation after sand precipitates completely: Sand content = [(volume of sand ml) / (volume of the drilling fluid sample in ml)] × 100% 6. The maintenance of the instrument (1) Wash all parts of the instrument with water before testing. (2) Wash all parts of the instrument with clean water, then wipe them up and take care of properly after testing (3) Forbid strictly to use exceptional outside force to the filtration screen in order to avoid making it damage or deform, and...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos RIGCHINA GROUP COMPANY

-

12 Speed Viscometer

23 Páginas

-

6 Speed Viscometer

23 Páginas

-

Garrett Gas Train

28 Páginas

-

Automatic Advanced Core Flood System

16 Páginas

-

Core Saturator

4 Páginas

-

Mechanical Dynamometer 2016

3 Páginas

-

Deadline Anchors

11 Páginas

-

Weight Indicator systems

11 Páginas

-

PRESSURE GAUGE MODEL 8

5 Páginas

-

REMOVE PRESSURE INDICATOR SYSTEMS

9 Páginas

-

COMPOUND POINTER PRESSURE GAUGE

3 Páginas

-

MUD PUMP PRESSURE GAUGES

19 Páginas

-

PRESSURE GAUGE TYPE F (MODEL 6)

5 Páginas

-

CATALOGUE MUD TESTING EQUIPMENT 2014A

72 Páginas

-

DRILLING INSTRUMENTATION

38 Páginas

-

PRESSURE GAUGE TYPE D (MODEL 7)

5 Páginas

-

Extreme Pressure & Lubricity Tester

19 Páginas

-

Automated Digital Rheometer NRC-130

14 Páginas

-

Automated Digital Rheometer NRC-132

15 Páginas

-

Oil and Water Retort Kit

19 Páginas