Excertos do catálogo

Vision System FH series Industry’s Fastest Compact Vision System Easy to Integrate in Machines » Increase Machine Speed

Abrir o catálogo na página 1

Industry’s Fastest* Compact Vision System A New Concept in Image Processing That Considers It’s time to move beyond simply increasing the speed of image processing and start seriously shortening Machine cycle time. This is the concept that gave birth to OMRON’s FH-series Vision System and its best-in-the-industry speed. Manufacturing Machines are operated through the interaction of sensors, PLCs, servomotors, and other devices. Vision Systems measure positions and perform inspections, and the results are used to control the operation of Machines. The demand for faster, more precise Vision...

Abrir o catálogo na página 2

Machine Cycle Time Increase Machine Speed High-speed Response to Execution Instructions from a PLC A high-speed image bus and 4-core processing increase the speed at every step, from image input to data output. Multiple camera inspections provide total judgement results Calculations are easy to set for the results from four parallel tasks. Quickly Outputting Measurement Results to a PLC You can output results to an NJ-series Machine Automation Controller on an EtherCAT communications cycle of 500 μs. Perform High-precision Machine Operation Measurements for Out-of-focus or Rotated Images...

Abrir o catálogo na página 3

Increase Machine Speed FH Process Higher-resolution Images without Increasing the Machine Cycle Time High-speed Image Input Realtime Image Transfer Camera resolution, driven by higher expectations for quality, continues to increase. OMRON has greatly reduced the input time and image transfer time to provide high-speed processing to match the speed of Machine applications for high-resolution images. Even with more Cameras and higher resolution, high-speed image input will contribute to increasing throughput. High-resolution Cameras capture large amounts of data, which can make a bottleneck...

Abrir o catálogo na página 4

Four-core CPU* to Meet High-speed Demands for Different Machines *for high speed controllers only Case1 Perform Calculations for Multiple Cameras without Delay Even when the measurement results of sequential operations are dependent on the speed of the independent action, parallel processing allows high speed performance without any dwell time. The measurement results from four cores can be easily calculated on one Controller to achieve continuous interaction without any special programming. Measuring chip position Measuring gripping position Determining placement position Confirming...

Abrir o catálogo na página 5

Increase Machine Speed FH Four-core CPU* to Meet High-speed Demands for Different Machines *for high speed controllers only Case2 Machine Cycle Time Reduced to 1/4* of Previous Time Case3 Process Multiple Lines in Parallel without Any Waiting Time Four cores process triggers, so the trigger interval can be 1/4th* of previous models. *In-house comparison. Four controllers are compressed into one without increasing the line cycle time. You can greatly reduce costs for processes that involve many lines. Standard Vision Sensors Image input Image input Measurement processing Image input...

Abrir o catálogo na página 6

Fast Output of Measurement Results to Reduce Machine Cycle Time EtherCAT Machine Control Network EtherCAT is a high-speed open network that is ideal for Machine control. You can use EtherCAT to connect to NJ-series Machine Automation Controllers and motion control G5-series Servomotors and Servo Drives to increase the control speed over everyday communications protocols from workpiece detection to starting axis motion. Communications Cycle Conventional communications standard Time from Trigger Input to Producing Measurement Results Trigger input Conventional communications standard Motion...

Abrir o catálogo na página 7

Perform High-precision Machine Operation FH The High-precision Image Processing Required for Positioning Shape Search III Low-error Position Detection Even with Blurry Images Over the years, OMRON has perfected techniques to search for and match templates at high speed. From these techniques Shape Search III provides advanced robustness, which is critical on FA sites. When measuring lamination of glass or other processes where the distance to the workpiece from the Camera varies, size dierences and focal shifts can occur. Even in cases like this, the new Shape Search III algorithm detects...

Abrir o catálogo na página 8

Converting Measurement Results to Output User Units Support for the Main Stages and Robots Used for 2D Positioning User Interface Example Item XY Camera axis movement: None Camera axis movement: X axis θ axis: Direct drive The FH Controllers contain special setup displays for the stages and robots that are commonly used on FA sites. You just ll in the settings to easily output axis travel amounts for stages and robots. Camera axis movement: Y axis Camera axis movement: XY axes Camera axis movement: None Camera axis movement: X axis θ axis: Linear drive Camera axis movement: Y axis Camera...

Abrir o catálogo na página 9

Easy to Integrate in Machines FH Easily Connect the Components That Configure the Machine Easy Integration into an Machine Monitor Support for .NET User Interface Controls Custom .NET controls are supported so that you can easily display FH Controller measurement images and measurement results on a Machine PC. Integrated Machine Monitor FH RUN Production Lot No. Test ○Process Timer setting Main menu Robot operation Easy Customization Custom controls for FH measurement images and measurement results are laid out on Microsoft Visual Studio®. riting Instead of writing the program code from...

Abrir o catálogo na página 10

Design the Connected Components with One Software Application Develop Machine Control Programs with One Software Application: Sysmac Studio Use the Automation Software Sysmac Studio to set up all of the slaves connected via EtherCAT. Simulate and debug motion control, logic, drives, and sensing on an integrated platform to reduce the work required for Machine design. One Software Sysmac Studio version 1.07 or higher supports the FH Series. NJ-series Machine Automation Controller FH-series Vision System G5-series Servomotors and Servo Drives Minimize Commissioning and Adjustment Work with...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos OMRON

-

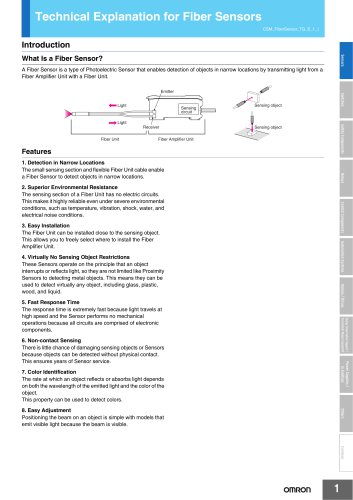

Technical Explanation for Fiber Sensors

14 Páginas

-

D4F

8 Páginas

-

D4GS-N

11 Páginas

-

E4E2

5 Páginas

-

Smart Laser Sensors E3NC-L/E3NC-S

16 Páginas

-

Fiber SensorBest Selection Catalog

104 Páginas

-

Fiber Unit E32-LT/LD

4 Páginas

-

G9SE Series

20 Páginas

-

NX-SL/SI/SO

20 Páginas

-

G9SP

28 Páginas

-

G9SX-SM

24 Páginas

-

G9SX-SM/LM

9 Páginas

-

G9SX/G9SX-GS

49 Páginas

-

G9SX-LM

28 Páginas

-

G9SB

10 Páginas

-

G9SA

16 Páginas

-

DST1 Series

5 Páginas

-

WS02-CFSC1-E

3 Páginas

-

G9SA-300-SC

9 Páginas

-

K8AK-AS

12 Páginas

-

K8AK-AW

16 Páginas

-

K8AK-VS

12 Páginas

-

K8AK-VW

12 Páginas

-

K8AK-PH

12 Páginas

-

K8DS-PH

12 Páginas

-

K8AK-PM

16 Páginas

-

K8DS-PM

12 Páginas

-

K8AK-PA

12 Páginas

-

K8DS-PA

12 Páginas

-

K8AK-PW

12 Páginas

-

K8DS-PU

12 Páginas

-

K8DS-PZ

12 Páginas

-

K8AK-TS/PT

12 Páginas

-

K8AK-LS

12 Páginas

-

K8AK-TH

12 Páginas

-

K2CM

16 Páginas

-

SE

15 Páginas

-

SAO

13 Páginas

-

APR-S

6 Páginas

-

XS5

25 Páginas

-

XS2

29 Páginas

-

F92A

4 Páginas

-

GLS

3 Páginas

-

TL-L

5 Páginas

-

V680 series

68 Páginas

-

V680S Series

68 Páginas

-

MY

35 Páginas

-

Safety Light Curtain F3SG-R Series

80 Páginas

-

E3NC-L/-S

16 Páginas

-

61F-GPN-BT / -BC

5 Páginas

-

NE1A-SCPU Series

8 Páginas

-

NE1A-SCPU0[]-EIP

8 Páginas

-

NE0A-SCPU01

6 Páginas

-

LY

14 Páginas

-

G2R-[]-S

11 Páginas

-

G7T

7 Páginas

-

G2A

9 Páginas

-

G2A-434

7 Páginas

-

G2AK

7 Páginas

-

MK-S

9 Páginas

-

MK-S(X)

12 Páginas

-

MM

17 Páginas

-

MMK

14 Páginas

-

G4Q

6 Páginas

-

G7Z

9 Páginas

-

G7J

10 Páginas

-

E4B

12 Páginas

-

E4A-3K

9 Páginas

-

E4C-UDA

5 Páginas

-

E6H-C

5 Páginas

-

E6F-C

5 Páginas

-

E6D-C

5 Páginas

-

E6B2-C

5 Páginas

-

E6A2-C

5 Páginas

-

NL

8 Páginas

-

VB

5 Páginas

-

SC

5 Páginas

-

D5F

5 Páginas

-

D5A

8 Páginas

-

E3S-GS3E4

3 Páginas

-

E3S-R

11 Páginas

-

E3S-A

21 Páginas

-

E3S-CL

9 Páginas

-

E3ZM-C

14 Páginas

-

E3T Data Sheet

26 Páginas

-

E3T Series

6 Páginas

-

G5 Series

59 Páginas

-

Sysmac Catalog

410 Páginas

-

VT-X700

6 Páginas

-

E5AC-T

8 Páginas

-

CP1

12 Páginas

-

CP1E

12 Páginas

-

MS4800

40 Páginas

-

VC-DL100

6 Páginas

-

FZ4 Series

42 Páginas

-

ZG2

16 Páginas

-

ZS Series

32 Páginas

-

ZW Series

24 Páginas

-

E9NC-T

2 Páginas

-

CompoNet

28 Páginas

-

F3SJ Series Safety Light Curtain

108 Páginas

-

Code Reader/OCR

24 Páginas

-

Fiber Sensor Best Selection Catalog

100 Páginas

-

Portable Multi-logger ZR-RX70

12 Páginas

-

Air Particle Sensor ZN-PD-S

2 Páginas

-

Smart Fiber Amplifier Units E3NX-FA

8 Páginas

-

NT series

18 Páginas

-

Programmable Controller SYSMAC CVM1

16 Páginas

-

Round Water-resistant Connectors

31 Páginas

-

Modular Temperature Controller EJ1

24 Páginas

-

Safety Controller G9SP

28 Páginas

-

E3FA PHOTOELECTRIC SENSORS

24 Páginas

-

Switch Mode Power Supply S8VK-G

22 Páginas

-

Data Logger ZR-RX Series

12 Páginas

-

Programmable Terminals NS Series

57 Páginas

-

DeviceNet Safety System

30 Páginas

-

Switching Power Supplies

16 Páginas

-

Photomicro Sensors

7 Páginas

-

Displacement Sensors

4 Páginas

-

R87F / R87T AC Axial Fans

28 Páginas

-

G9SX-GS Safety Guard Switching Unit

28 Páginas

-

H8PS Cam Positioner

32 Páginas

-

OS32C Safety Laser Scanner

24 Páginas

-

FQ Vision Sensor

17 Páginas

-

UM, MC3 Safety Mat/Safety Mat Controller

19 Páginas

-

ZN-PD Air Particle Sensor

16 Páginas

-

ZUV-C20H / C30H Smart Curing System

14 Páginas

-

E5CC Digital Temperature Controller

38 Páginas

-

S8EX Switch Mode Power Supply

24 Páginas

-

CP1L CP series CP1L CPU Unit

36 Páginas

-

E2EF

8 Páginas

-

FQ2 Smart camera

24 Páginas

Catálogos arquivados

-

SAFETY APPLICATION HANDBOOK

55 Páginas

-

SMART REMOTE I/O

12 Páginas

-

Sensor Accessories

38 Páginas

-

REGULATION SOLUTIONS

24 Páginas

-

Vision Systems

20 Páginas

![NE1A-SCPU0[]-EIP](https://img.directindustry.com/pdf/repository_di/15954/ne1a-scpu0-eip-616667_1mg.jpg)

![G2R-[]-S](https://img.directindustry.com/pdf/repository_di/15954/g2r-s-616653_1mg.jpg)