Website:

NETZSCH Grinding & Dispersing

Website:

NETZSCH Grinding & Dispersing

Grupo: NETZSCH

Excertos do catálogo

Proven Excellence. Agitator Bead Mill Alpha® The next Generation of Agitator Bead Mills CHEMICAL INDUSTRY a Business Field of NETZSCH Grinding & Dispersing

Abrir o catálogo na página 1

NETZSCH Alpha® The next Generation of Agitator Bead Mills Agitator bead mills are grinding machines for ultra-fine processing of solids in liquids. Their area of application covers the particle size range from 200 µm (max. 500 µm) down to the submicron (nanometer) range. With a comminution factor down to 1 : 10 000 (200 µm 20 nm), the application range is extensive and the variety of tasks extremely diverse. The wetting and homogenization of solids in liquids, deagglomeration and dispersion, all the way to true comminution of primary particles make the agitator bead mill a universal wet...

Abrir o catálogo na página 2

Fresh creative standards were also set for the new Alpha® from the very beginning and a new expression of form was used that distinctly communicates the innovative strength of NETZSCH in the design as well. In place of the cast housing, external instruments and pipework there is a clear, dynamically-curved welded construction of heavy plating which also fulfills a load-bearing function. The ergonomic design of the machine stand was a primary consideration during the development phase. The Alpha® has a self-supporting grinding chamber, which ensures good accessibility to the grinding area...

Abrir o catálogo na página 3

NETZSCH Alpha® Modular Machine Platform for Customized Solutions The new Alpha® sets the standard when it comes to flexibility and handling and, thanks to its modularity, allows customer-specific solutions: different grinding systems can be mounted on one base stand – customized for the requirements of the product you need to process. The advantage this modular system brings you is cross-system standardization and thus the option to economically convert a machine to a new grinding system. In addition, the Alpha® is also the platform for future NETZSCH technologies, which guarantees you...

Abrir o catálogo na página 4

Focus on Your Benefits Common platform for three grinding systems allows easy conversion to the respective optimal process conditions Long-term investment security, since the Alpha® is also the platform for future NETZSCH technologies Self-supporting grinding chamber for optimum accessibility to the grinding area during maintenance All supply lines feed into the machine from the top, which prevents obstructions at ground level Optimal accessibility to the parts in the machine stand that must be maintained Spatial separation of rotating machinery and media-carrying fittings ensures a high...

Abrir o catálogo na página 5

The NETZSCH Alpha® Discus system is the quantum leap in disk grinding technology. The further optimized Discus disk agitator combined with the NETZSCH DCC® separation system guarantees you extremely high throughput rates with significantly narrower dwell time distributions and therefore more intensive grinding with uniform impact intensity. The power input of the mill increases considerably, with a simultaneous increase in energy efficiency. The Discus grinding system activates and optimizes the movement of the grinding beads between the disks, which leads to a higher power input and a...

Abrir o catálogo na página 6

Continuous agitator bead mills with horizontal disk agitator With the Discus grinding system, the movement of the grinding media between the disks is activated and optimized. This leads to a high power input and a grinding efficiency with low specific energy consumption The product flows axially from the inlet through the grinding chamber and is stressed by the shearing, pressure and impact action of the grinding beads and thus ground or finely dispersed A highly effective centrifugal separation system allows the product to flow out, while the grinding beads are retained in the mill Discus...

Abrir o catálogo na página 7

NETZSCH Alpha® Discus System Highest Efficiency with Low Energy Consumption The Further Optimized Model DCC® Pre-Classifying Separation System The highly-efficient, dynamic centrifugal separation system makes it possible to use grinding media of various densities, matched to the task at hand. In addition, grinding beads as small as 0.2 mm in diameter can be used with this system. The separation system ensures that even with high viscosities the mill can be operated far below the critical point of grinding media compression. This means you maintain extremely stable operational performance,...

Abrir o catálogo na página 8

Material Options for any Product In order to meet the requirements of the widest range of products and to guarantee product compatibility, we offer a variety of grinding chamber materials. Matching the grinding chamber material to the product properties facilitates low-wear operation of the mill. The use of a low-contamination grinding chamber design leads to an enormous expansion of the possible product applications for the machine. Selection of Grinding Chamber Materials ■ Highly wear-resistant special steel ■ Stainless steel ■ NETZSCH-Ceram Z ■ NETZSCH-Ceram N ■ NETZSCH-Ceram C ■ NElast...

Abrir o catálogo na página 9

Suitable for every viscosity and almost any product, with this technology you will achieve the highest product qualities and finenesses into the nanometer range using a wide variety of grinding media from 0.1 mm to 3 mm in diameter. The closed horizontal agitator bead mill is designed for the highest product throughput rates and has a peg grinding system with extremely high grinding intensity. Alpha® Zeta® System Models Grinding chamber volume [l] Batch size [l] Drive [kW] Mini/Micro Serie 0.08 - 0.16 0.15 - 0.5

Abrir o catálogo na página 10

Easy and Reliable Operation The Zeta® grinding system is, in every respect, a user friendly, low-maintenance and very reliable grinding system. Starting with the structural design of the agitator mill, there is already a number of advantages: the horizontal orientation guarantees a homogeneous fill of the grinding media in the grinding tank. The start-up performance of the mill with product is therefore unproblematic and very high flow rates can be set without pressure build-up. The product outlet is located directly on the bottom of the grinding tank and is therefore easily accessible....

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos NETZSCH Grinding & Dispersing

-

NETZSCH MiniVac

2 Páginas

-

NETZSCH ConduxVita

4 Páginas

-

NETZSCH Pre-Grinding Mill ProPhi

12 Páginas

-

NETZSCH Zumba

4 Páginas

-

NETZSCH Image G&D

28 Páginas

-

NETZSCH Connect

4 Páginas

-

NETZSCH MiniSerie & MicroSerie

8 Páginas

-

CaseStudy Graphite Spheroidization

8 Páginas

-

Pamir

4 Páginas

-

Laboratory Mill MiniZeta

2 Páginas

-

NETZSCH MasterCream

8 Páginas

-

Salsa® System

12 Páginas

-

Process Technology for Food Applications

24 Páginas

-

NETZSCH-Beads®

20 Páginas

-

OmegaVita® High-pressure Homogenizer

4 Páginas

-

LambdaVita® Series Homogenizers

4 Páginas

-

GammaVita® Phase/Suspension Mixer

8 Páginas

-

KappaVita® Homogenizing Mixer

8 Páginas

-

NETZSCH Steam Jet Mill s-Jet®

20 Páginas

-

NETZSCH Classifier Mill CSM CERAMIC

8 Páginas

-

NETZSCH Classifier Mills CSM

12 Páginas

-

Milling of Spices

4 Páginas

-

NETZSCH Fine Impact Mill CONDUX®

12 Páginas

-

NETZSCH SPHERHO®

4 Páginas

-

NETZSCH Fine Classifier CFS

8 Páginas

-

EpsilonVita Inline Disperser

2 Páginas

-

Vacuum De-Aerator DA/DA-VS

8 Páginas

-

Inline Disperser MaxShear

4 Páginas

-

PMD-VC Intensive Mixers

8 Páginas

-

MasterMix® Dissolver

8 Páginas

-

Ψ-Mix® Inline-Disperser

12 Páginas

-

LabStar Laboratory Agitator Bead Mill

12 Páginas

-

Discus Intensive Grinding System

12 Páginas

-

NETZSCH Mill Control Systems

12 Páginas

-

Process Technology for Printing Inks

16 Páginas

-

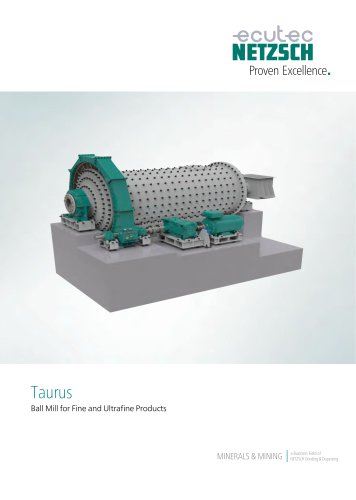

Atlas Vertical Roller Mill

4 Páginas

-

URAL | Air classifier mill

4 Páginas

-

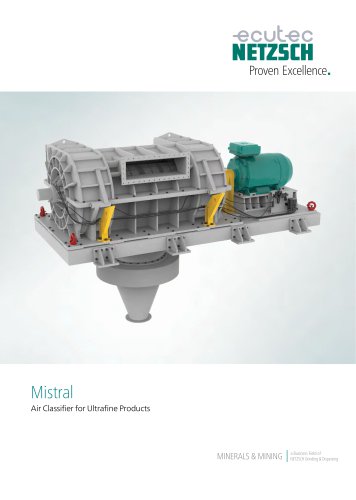

Bora Air Classifier

4 Páginas

-

Economic Dispersionizer Omega® Lab

2 Páginas

-

MONSOON | Whizzer Classifier

4 Páginas

-

Discus Grinding System

12 Páginas

-

Economic Dispersionizer Omega®

8 Páginas

-

Nanomill Zeta RS

20 Páginas

-

Zeta® Grinding System

8 Páginas

-

Epsilon Inline Disperser

8 Páginas

-

AfterSales Support

16 Páginas

-

NETZSCH CaseStudy Tango

8 Páginas

-

Process Technology for Digital Inks

28 Páginas

-

Discus Intensive Rotor

12 Páginas

-

Grinding System Neos®

12 Páginas

-

Netzsch filter and cyclones

12 Páginas

-

NETZSCH SmartRemoval

4 Páginas

-

Fine-Grinding and Fine-Classifying

24 Páginas

-

NETZSCH KappaVita Laboratory Mixers

8 Páginas

-

NETZSCH Fluidized Bed Jet Mill CGS

12 Páginas

-

Process Technology for Agrochemicals

24 Páginas

-

NETZSCH Toll Grinding

8 Páginas

-

Agitator Bead Mill DeltaVita®

12 Páginas

-

NETZSCH_DeltaVitaMini

4 Páginas

-

ALPHA®LAB

2 Páginas

-

Fine Cutting Mill SecoMy

8 Páginas

-

Laboratory Plants

20 Páginas

-

NETZSCH Case Study Sakata

8 Páginas

-

NETZSCH Case Study S&S

8 Páginas

-

NETZSCH Case Study Sun Chemical

8 Páginas