Excertos do catálogo

ArcWorld 6000ArcWorld II-6000SOLUTIONS IN MOTION® ArcWorld II-6000 n ArcWorld II-6000HD n ArcWorld II-6200 n ArcWorld II-6200HD The ArcWorld II-6000 is a fully integrated, standardized arc welding solution with a trunnion type positioner. It is designed to easily handle complex applications that require welding in multiple planes. This workcell provides flexibility without the cost of high-volume Tier One features. AWII-6000 series feature the high-speed MA1400 or MA1900 "Master Arc" robots, DX100 controller with menu-driven arc welding application software, integrated welding package, MRM2 trunnion positioner and operator station. Its total safety environment is in compliance with ANSI/RIA R15.06-1999 and Canadian safety standards. Reduced Cost n Robot, controller, power source and positioner are lagged to the floor rather than mounted on equipment bases. n Twist-lock connectors are included on all interconnecting cables. n Workcell is available with two positioner spans to suit application and optimize floorspace n If bases are desired, they are provided in the AW6000 and AWIV-6000 configurations. Master Arc Robots n Available with one or two MA1400 arc welding robots. Dual-robot workcells double productivity. n The extended-reach MA1900 provides nearly two meters of reach to access larger workpieces. n Unique, integrated torch cable design of the MA-series robots eliminates cable interference. This makes programming easier and reduces wear and associated cable maintenance downtime. n MA-series robots are backed by the industry’s only two-year torch cable warranty. DX100 Controller n Windows® CE programming pendant with color touch screen, fast processing, easy-to-use INFORM III programming language and robust PC architecture. n Menu-driven arc welding software including graphic diagram of weld parameter settings. n Safety features – enhanced dual-channel E-Stop functionality, integrated speed monitoring, manual brake release for the robot and compliance with both U.S. and Canadian safety standards. Part Positioner: MRM2-250STN or MRM2-500STN (HD) n Coordinated HS/TS axis allows circumferential welds to be performed in one pass. n 250-kg (551.25 lb) payload. n 2-second index time provides high-volume production. n 1,170 mm (46.1") maximum part diameter. n Two spans available: 1,600 mm (63") or 2,600 mm (102.4") for AWII-6000; 1,600 mm (63") or 3,000 mm (118.1") for AWII-6000HD. n The MRM2-500STN, with a 500-kg (1,102.5 lb) payload and larger 1,350 mm part diameter/span is available with the AWII-6000/6200HD versions. It has a 5-second index time. n Patented design uses a single servo motor to drive both the HS and TS in front of the robot and the robot's main sweep axis. n Use of a single motor reduces cost and improves reliability due to fewer components. Customer Satisfaction n Motoman is committed to delivering the best customer satisfaction in the robot industry. n 24-hour technical and field service support, industry-leading warranties and maintenance protection plans. n Motoman has world-class training facilities and is dedicated to instructing customers in safe, effective programming and operation of their robots. ARM YOURSELF …with an ArcWorld II-6000. A cost-effective, efficient system for robotic arc welding with high-volume production results…packaged in a complete, low-risk, industry-proven solution. HIGHLIGHTS TOP 3 REASONS TO BUY! n Highest value workcell; functionality vs. low price n Ideal for job shops; high flexibility with coordinated part positioning n Patented part positioner is the world’s most popular with more than 5,000 units installed worldwide master arc Robots improve partpart access Dual robots maximize productivitywith DX100 Controller

Abrir o catálogo na página 1

Motoman CORPORATATE HEADQUARTERS 805 Liberty Lane, WEST CARROLLTONTON, OHIO 45449 Tel : 937.847.6200 • FAX: 937.847.6277 T ECHNICAL SPECIFICATIONATIONS SUBJECT TOTO CHANGE WITHOUT NOTICE DS-444 ©2010 MOTOOTOMAN INC. january 2010 MOTOOTOMAN IS A REGISTERED TRADEMARK Windows is a registered trademark of Microsoft PanelView is a Trademark of Rockwell Automation A LL OTHER MARKS ARE THE TRADEMARKS OR REGISTERED TRADEMARKS OF MOTOOTOMAN INC. C ONFIGURATION OPTIONS n MA1900 extended-reach robots n Higher payload positioner, MRM2-500STN, with 500 kg (1,102.5 lb) payload, available with the...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos MOTOMAN

-

SDA10D

2 Páginas

-

SIA20D

2 Páginas

-

SIA10D

2 Páginas

-

SDA20D

2 Páginas

-

SDA10F

2 Páginas

-

SDA20F

2 Páginas

-

SDA5F

2 Páginas

-

SIA10F

2 Páginas

-

SIA20F

2 Páginas

-

SIA30D

2 Páginas

-

SIA50D

2 Páginas

-

SIA5D

2 Páginas

-

SIA5F

2 Páginas

-

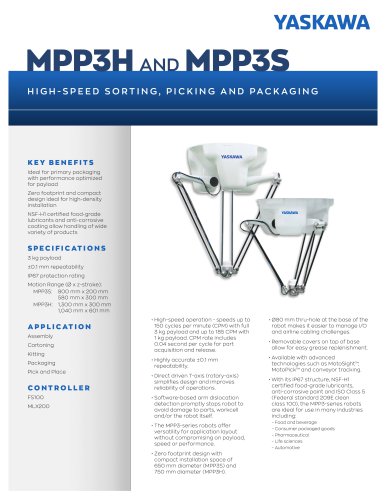

MPP3H AND MPP3S

2 Páginas

-

YRC1000

2 Páginas

-

HC10DTP

2 Páginas

-

MotoMini Compact, Lightweight Design

2 Páginas

-

AR700

2 Páginas

-

AR1440

2 Páginas

Catálogos arquivados

-

MA3120

2 Páginas

-

MH50 II-20

2 Páginas

-

MA2010

2 Páginas

-

HP20

2 Páginas

-

VA1400 II

2 Páginas

-

MH3BM

2 Páginas

-

MS165/MS210

2 Páginas

-

MA1440

2 Páginas

-

Motoman robots

7 Páginas

-

NX100 Controller

2 Páginas

-

FS100 Controller

2 Páginas

-

HP20RD

2 Páginas

-

HP20F

2 Páginas

-

HP20D-A80

2 Páginas

-

YSH850L

2 Páginas

-

MPP3

2 Páginas

-

MHJF

2 Páginas

-

MH6F

2 Páginas

-

MH5LS(MLX100)

2 Páginas

-

MH5F

2 Páginas

-

MH3F

2 Páginas

-

MH5S

2 Páginas

-

Motoman SDA5D "Slim, Dual-Arm" Robot

2 Páginas

-

Motoman FabWorld II

2 Páginas

-

Motoman Bottle Pack Solutions

2 Páginas

-

Motoman MotoSize Software

1 Páginas

-

Motoman Solutions - Heavy Weldments

2 Páginas

-

Motoman RobotPro DX Software

2 Páginas

-

Motoman MH6-Series Robots

2 Páginas

-

Motoman File Management System (FMS)

1 Páginas

-

Motoman MH50 and MH50-35 Robots

2 Páginas

-

Motoman MPK50 "Packing" Robot

2 Páginas

-

Motoman MPK2 5-Axis "Picking" Robot

2 Páginas

-

Motoman HP20D and HP20D-6 Robots

2 Páginas

-

Motoman SIA50D 7-Axis Robot

2 Páginas

-

Motoman MH50-20 Robot

2 Páginas

-

Motoman YS850L 4-Axis SCARA Robot

2 Páginas

-

Motoman YS650L 4-Axis SCARA Robot

2 Páginas

-

Motoman YS650 4-Axis SCARA Robot

2 Páginas

-

Motoman YS450 4-Axis SCARA Robot

2 Páginas

-

Motoman Press Tending Solutions

2 Páginas

-

Motoman MotoSight 2D Vision Solution

1 Páginas

-

Motoman MotoSight 3D Vision Solution

1 Páginas

-

Motoman Points Importer EG Software

2 Páginas

-

Motoman MotoFTP Software

1 Páginas

-

Motoman MotoCalv EG Software

2 Páginas

-

Motoman G-Code Converter EG

2 Páginas

-

Motoman Customer Satisfaction

7 Páginas

-

Motoman Robot Series Brochure

7 Páginas

-

Motoman Solutions - Machine Tending

6 Páginas

-

Motoman Positioner Brochure

12 Páginas

-

Motoman Corporate Brochure

12 Páginas

-

Motoman Machine Tending Brochure

4 Páginas

-

Motoman Arcworld & FabWorld Solutions

12 Páginas