Excertos do catálogo

The ArcWorld > ή II-100 provides an affordable, wire-to-weld solution for welding small to medium workpieces at low to medium volumes. A two-station turntable positioner enables the operator to efficiently load/unload parts from a single point. The standard AWII-100 model has a compact footprint and requires minimal installation space. The ArcWorld II-100 features a MA1400 Master ArcӔ welding robot, DX100 controller with menu-driven arc welding application software, integrated welding package and indexing positioner. Its total safety environment complies with ANSI/RIA R15.06-1999, ANSI/RIA/ISO 10218-1-2007 and Canadian CSA Z434-03 safety standards. > MA1400 robots are backed by the industrys only two-year torch cable warranty. Designed to accommodate single or multiple fixture part runs. Fixtures are easily located on the table using dowel pins. Fixture plates are available as an option. All equipment is designed to be lagged to the floor. As an option, equipment can be shipped pre- assembled on a common base to reduce setup time. > Windows > Ү CE programming pendant with color touch screen, fast processing, easy-to-use INFORM III programming language and robust PC architecture. > FIXTURES CAN BE CHANGED QUICKLY System cables are routed overhead to improve cable life and minimize trip hazards. > Motoman is committed to delivering the best customer satisfaction in the robot industry. Cell features convenient, fence-mounted cycle start (latching) and E-stop buttons. Menu-driven arc welding software including graphic diagram of weld parameter settings. 24-hour technical and field service support, industry-leading warranties and maintenance protection plans. Total safety environment includes dual-channel safety-rated, tamper-resistant interlocks; complete barrier guarding; single point of operator control; access doors on each side of the cell; and dual-channel light curtains (mounted diagonally to reduce floorspace requirements). Safety features enhanced dual-channel E-Stop functionality, integrated speed monitoring, manual brake release for the robot, and compliance with both U.S. and Canadian safety standards. Motoman has world-class training facilities and is dedicated to instructing customers in safe, effective programming and operation of their robots. > MA1400 GREATLY ENHANCES WELD PERFORMANCE ...with the high performance of a fully integrated robotic welding solution at an affordable price. MA1400 ԓMaster Arc robot features a 3 kg payload, 1,434 mm reach and Ա0.08 mm repeatability. MSR-200 positioner (AWII-100) features a 200 kg (441-lb) payload capacity per side, and uses a servo-motor for indexing. > Worlds fastest arc welding robots can reduce cycle time by 15 percent, greatly enhancing productivity. Provides accurate part positioning with an indexing time of approximately 4 seconds. > Unique, integrated torch cable design of the MA1400 robot eliminates cable interference. This makes programming easier and reduces wear and associated cable maintenance downtime. Low-inertia H-frame tabletop featuring a 1,524 mm (60") turning diameter with dowel pins for repeatable fixture locations. >

Abrir o catálogo na página 1

ArcWorld II-100 shown. All dimensions are metric (mm) and for reference only. Please request detail drawings for all design/engineering requirements. > ArcWorld MSR-200 200 kg (441 lb) payload capacity Part Positioner per side HyperStart Welding Package (AWII-100) 2-position, 180ٰ sweep Approximately 4-second index time 1,524 mm (60") dia. table Weld-in-Teach mode function Integrated air-cooled torch Master ArcӔ hollow shock sensor Arm-mounted 4-roll wire feeder Welding power source Two-year torch cable warranty > Total Safety Safety-rated, tamper-resistant Environment interlocks > Operator...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos MOTOMAN

-

SDA10D

2 Páginas

-

SIA20D

2 Páginas

-

SIA10D

2 Páginas

-

SDA20D

2 Páginas

-

SDA10F

2 Páginas

-

SDA20F

2 Páginas

-

SDA5F

2 Páginas

-

SIA10F

2 Páginas

-

SIA20F

2 Páginas

-

SIA30D

2 Páginas

-

SIA50D

2 Páginas

-

SIA5D

2 Páginas

-

SIA5F

2 Páginas

-

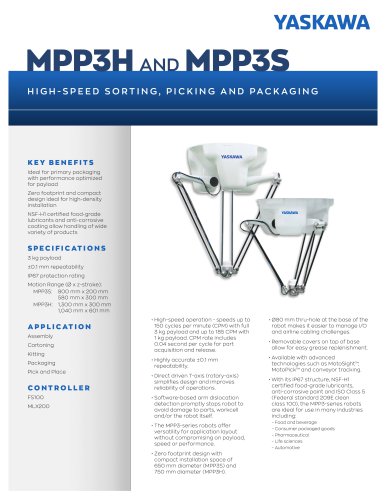

MPP3H AND MPP3S

2 Páginas

-

YRC1000

2 Páginas

-

HC10DTP

2 Páginas

-

MotoMini Compact, Lightweight Design

2 Páginas

-

AR700

2 Páginas

-

AR1440

2 Páginas

Catálogos arquivados

-

MA3120

2 Páginas

-

MH50 II-20

2 Páginas

-

MA2010

2 Páginas

-

HP20

2 Páginas

-

VA1400 II

2 Páginas

-

MH3BM

2 Páginas

-

MS165/MS210

2 Páginas

-

MA1440

2 Páginas

-

Motoman robots

7 Páginas

-

NX100 Controller

2 Páginas

-

FS100 Controller

2 Páginas

-

HP20RD

2 Páginas

-

HP20F

2 Páginas

-

HP20D-A80

2 Páginas

-

YSH850L

2 Páginas

-

MPP3

2 Páginas

-

MHJF

2 Páginas

-

MH6F

2 Páginas

-

MH5LS(MLX100)

2 Páginas

-

MH5F

2 Páginas

-

MH3F

2 Páginas

-

MH5S

2 Páginas

-

Motoman SDA5D "Slim, Dual-Arm" Robot

2 Páginas

-

Motoman FabWorld II

2 Páginas

-

Motoman Bottle Pack Solutions

2 Páginas

-

Motoman MotoSize Software

1 Páginas

-

Motoman Solutions - Heavy Weldments

2 Páginas

-

Motoman RobotPro DX Software

2 Páginas

-

Motoman MH6-Series Robots

2 Páginas

-

Motoman File Management System (FMS)

1 Páginas

-

Motoman MH50 and MH50-35 Robots

2 Páginas

-

Motoman MPK50 "Packing" Robot

2 Páginas

-

Motoman MPK2 5-Axis "Picking" Robot

2 Páginas

-

Motoman HP20D and HP20D-6 Robots

2 Páginas

-

Motoman SIA50D 7-Axis Robot

2 Páginas

-

Motoman MH50-20 Robot

2 Páginas

-

Motoman YS850L 4-Axis SCARA Robot

2 Páginas

-

Motoman YS650L 4-Axis SCARA Robot

2 Páginas

-

Motoman YS650 4-Axis SCARA Robot

2 Páginas

-

Motoman YS450 4-Axis SCARA Robot

2 Páginas

-

Motoman Press Tending Solutions

2 Páginas

-

Motoman MotoSight 2D Vision Solution

1 Páginas

-

Motoman MotoSight 3D Vision Solution

1 Páginas

-

Motoman Points Importer EG Software

2 Páginas

-

Motoman MotoFTP Software

1 Páginas

-

Motoman MotoCalv EG Software

2 Páginas

-

Motoman G-Code Converter EG

2 Páginas

-

Motoman Customer Satisfaction

7 Páginas

-

Motoman Robot Series Brochure

7 Páginas

-

Motoman Solutions - Machine Tending

6 Páginas

-

Motoman Positioner Brochure

12 Páginas

-

Motoman Corporate Brochure

12 Páginas

-

Motoman Machine Tending Brochure

4 Páginas

-

Motoman Arcworld & FabWorld Solutions

12 Páginas