Website:

Minebea Intec GmbH

Website:

Minebea Intec GmbH

Grupo: MinebeaMitsumi

Excertos do catálogo

Minebea intec The true measure Best practice Minebea Intec responded quickly to customer requirements with X-ray solution When HCP Health Care Products Ltd. needed a foreign object detection solution quickly, it was the speedy response of the Minebea intec Sales team combined with the availability of a Dylight X-ray machine that led Minebea intec to be its supplier of choice. Key facts HCP produces sweeteners in tubs which have a 90 mm diameter and are 100 mm high. They are sealed with a screw top but also have a metal foil lid. Due to the nature of the packaging, the team at HCP knew they would not be able to detect the full range of metals, including stainless steel. Application The X-ray inspection system needed to be placed as a critical control point. The key factors at the time were the lead times and whether the system could be commissioned on site within a very short period of time. Products ■ X-ray inspection system Dylight Customer benefits Rob Barker, Factory Manager at HCP states: "The most important thing about a machine like this is you can for the best part ignore it and just know it's there doing a job well. Since the machine has been in, it's not missed a beat. We have been immensely pleased with the reliability and performance." Customer HCP Health Care Products Ltd., The Sweetener Company, was established over 25 years ago and is now the largest sweetener tablet producer in the UK. The company manufactures sweetener tablets and sweetener products for large brands and supermarkets in the UK and internationally.

Abrir o catálogo na página 1

Project goal and implementation HCP was asked by its customer to find an X-ray solution to overcome the packaging challenge which it had at the PPMA show in 2017. Among a number of other potential suppliers, it came across Minebea Intec. Derby to discuss the application and solution. HCP had already notified HSE (Health and Safety Executive in UK) that they would be using X-ray systems soon. Andrew quickly responded to Bob’s query and invited him to the Minebea Intec showroom in Birmingham to see the Due to the nature of its packaging containing a screw top and available equipment in a test...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos Minebea Intec GmbH

-

Best Practice Avio

2 Páginas

-

Datasheet LC Tigo

5 Páginas

-

Datasheet LC Aluminium

4 Páginas

-

Datasheet PR 6246

4 Páginas

-

Best Practice Anona

2 Páginas

-

Best Practice Ramsauer

2 Páginas

-

Best Practice Braskem

2 Páginas

-

Best Practice ADLER

2 Páginas

-

Best Practice SABIC

2 Páginas

-

Best Practice Bhilai Steel Plant

2 Páginas

-

Best Practice MIXACO

2 Páginas

-

Best Practice Pacific Nut

2 Páginas

-

Best Practice Weinrich

2 Páginas

-

Datasheet BCL-A

1 Páginas

-

Datasheet U2D1

2 Páginas

-

Datasheet PR 5220

4 Páginas

-

Datasheet CB17

1 Páginas

-

Best Practice Valle Spluga

2 Páginas

-

Best Practice Sinovac

2 Páginas

-

Best Practice Pharmatec

2 Páginas

-

Best Practice Boehringer Ingelheim

2 Páginas

-

Best Practice Confectionery Company

2 Páginas

-

Best Practice LDO

2 Páginas

-

Datasheet Dypipe

6 Páginas

-

Datasheet X2

4 Páginas

-

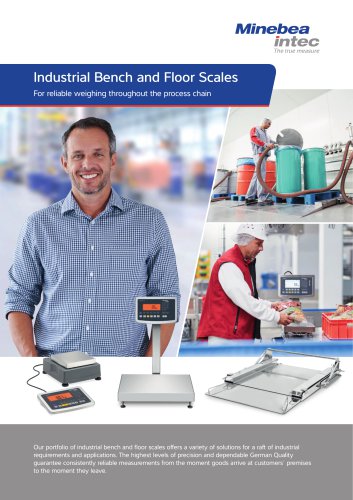

Brochure Bench and Floor Scales

24 Páginas

-

Brochure X-ray Inspection

16 Páginas

-

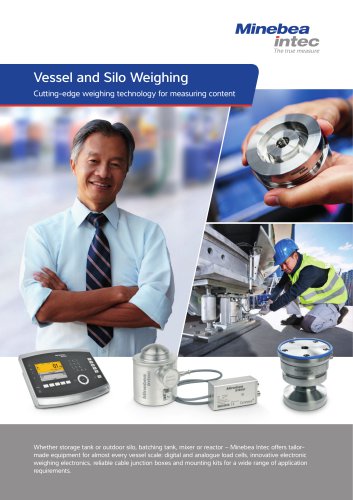

Brochure Vessel and Silo Weighing

28 Páginas

-

Brochure Statistical Process Control

16 Páginas

-

Best Practice: CanSino

2 Páginas

-

Best Practice: Pacific Nut

2 Páginas

-

Best Practice: Pharmatec

2 Páginas

-

Best Practice: Boehringer Ingelheim

2 Páginas

-

Best Practice automotive supplier

2 Páginas

-

Best Practice Adler Lacke

2 Páginas

-

Best Practice Stevin Rock

2 Páginas

-

Company Presentation Minebea Intec

9 Páginas

-

Datasheet PR 5211

4 Páginas

-

Datasheet Weight Transmitter Link E

3 Páginas