Website:

Matthiessen Lagertechnik GmbH

Website:

Matthiessen Lagertechnik GmbH

Grupo: Butzkies Stahlbau Group

Excertos do catálogo

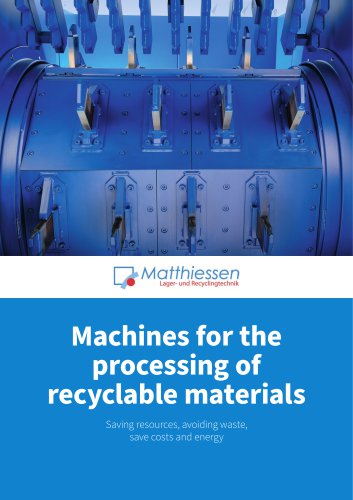

Machines for the processing of recyclable materials Saving resources, avoiding waste, save costs and energy

Abrir o catálogo na página 1

Innovative recycling tech for a cleaner future Safeguard resources, avoid waste, save on costs and energy – processing reusable materials in your waste is an important part of sustainable environmental protection. Matthiessen Lagertechnik offers a wide range of the latest machines that have been specially developed for the recycling industry to ensure the best possible start to the treatment process. The individual components can be combined as modules to create high-performance system components so you can achieve maximum recycling rates. Bale Breaker Dosing Bunker Quality: Made in...

Abrir o catálogo na página 2

Bag Splitter SR Around the world, Matthiessen Bag Splitter are working in the first phase of many recycling operations. These bag opener not only rip or split the bags, but also empty and meter the contents onto a conveyor. Materials are separated and prepared for downstream sorting and picking processes without being shredded into smaller pieces. Matthiessen Bag Splitter are also used as Bale Breaking or Dosing devices. Input-material MSW Bio-Waste Co-Mingled Paper and Cards Yellow bags/Light material Various Input-materials – Various Solutions Working Width 1,500 mm/1,750 mm/2,000 mm...

Abrir o catálogo na página 3

The ideal start to recycling Matthiessen Bag Splitter convince with maximum energy eff iciency at full capacity Equipped with modern control systems, these machines improve productivity and product quality while also reducing energy costs in the plant. Active Rotating Comb (ARK), rotor with retractable tines and round plates Bags are opened without compressing or shredding the contents or other loose material in the waste stream. Oversize, bulky material such as lawn chairs, pails stacked inside each other, styrofoam parts, big packages or similar articles are reduced to a manageable size....

Abrir o catálogo na página 4

In order to transport recycables after the first treatment step over long distances economically, these recycables are pressed to bales of different sizes. After transport these bales have to be loosened to supply the recycables to following processing steps. An inappropriate start to the preparation process therefore has a negative effect on the efficiency of the overall process. The Bale Breaker developed by Matthiessen enables economical preparation of recyclable materials and a perfect start for subsequent work processes. Matthiessen Bale Breaker BAIII Input-material Paper ■ PET-bottles...

Abrir o catálogo na página 5

Eff icient and safe solution Matthiessen Bale Breaker BAIV for the reliable loosening of bale material Matthiessen BANIII-DD Bale Breaker with integrated dewiring for more safety at the workplace After dewiring or dewrapping the bale, it is loaded into the feeding bunker by forklift or conveyor belt. This is equipped with a robust speed controlled chain belt. The traverses on the chain belt move the bales with a constant speed forward to the ripping rotor. Work safety has the highest priority today. To release bales from wires is a dangerous step when it needs to be done manually. Safety...

Abrir o catálogo na página 6

Very often, recycables are collected in bags. Unfortenately, just these bags, whether “yellow“ or “black“, as well as large foils, make a significant irritant for sorting processes in each treatment plant. Frequently, the screen linings and transfer points become clogged - even leading to complete plant shutdowns. In order to prevent this problem, the Matthiessen Oversize “Film” Remover separates the larger parts in the material flow and thus ensures smooth processes. Advantages ■ Output rate for films > DIN A2 > 70 % ■ Excellent recyclable material pre-sorting ■ Individual speed...

Abrir o catálogo na página 7

Smaller recycables such as Tetra Packs, bottles, organic substances etc. are conveyed under the rotor to be continued to the next processing step. Larger recycables, such as e.g. films, are pulled over the ripping rotor and drop on a belt behind the rotor, which conveys this material flow to the Oversize “Film” Remover. The Matthiessen Oversize Remover reliably separates films and other larger parts in advance. Oversized parts in the feed material, especially the films of trash bags, often cause clogging and blockages in sorting plants. Not infrequently, this results in a stop of the entire...

Abrir o catálogo na página 8

Every treatment process has its beginning. After delivery, many recycling plants send the material for processing. In case of errors at that point, the following process can never run smoothly. Best dosing facilitates subsequent best treatment. Individual adaptation possible Metals, shredding heavy or light fraction Compost, green waste, fine cut Industrial waste Household waste ■ Very robust chainbelt conveyor 1,600 mm - 2,200 mm ■ Moving floor (Seperate control of each plank!) 1,950 mm (with 8 planks) ■ Exchangeable carrier paddles for product changes without great design effort ■ Can be...

Abrir o catálogo na página 9

Always the right dosage Matthiessen Dosing Bunker combine reliable performance with maximum flexibility. Robustness and high availability are the distinguishing features of Matthiessen Dosing Bunker. The metering drum(s) are adapted to the specific task(s) and so almost every task product is supplied evenly to the treatment process. This is done by using our stable chain-beltconveyor or walking floors. Depending on the product and space this or that technology will prevail. Bunker volumes up to over 100m3 provide an optimal storage bunker, whose content is conveyed further. Moving floor...

Abrir o catálogo na página 10

Machines in daily use need the right care to be able to work continuously and trouble-free. Matthiessen Lagertechnik offers a comprehensive range of services to ensure smooth operations. In order to minimise downtimes, we offer you our services. We check and document all machine and system statuses, evaluate them and can use this information to recognise at an early stage when maintenance and repair work is to be expected. Our well-trained service team is able to help you quickly and reliably. Through targeted1 questions and years of experience we can often solve problems already on the...

Abrir o catálogo na página 11