Excertos do catálogo

Generating- and profile-grinding machines LGG 180 / 28

Abrir o catálogo na página 1

Machine Concept The new generating and profile grinding machine LGG 180/280 is suitable for the processing all gears up to 180/280 mm diameter. In addition, workpieces can be machined to 650 mm length. For special customer needs various machining variants are available. The generating and profile grinding machine combines short grinding times with consistently high quality in high-volume operations. • Higher quality and reliability across the entire lot size • Single-table solution - One clamping fixture, one geometry - For all gears up to 180/280 mm - Shaft length 500 mm (650 mm as L-version)...

Abrir o catálogo na página 2

Grinding heads Internal grinding heads The LGG machines are suitable for hob grinding and profile grinding. As standard, the machines are equipped with an external grinding head and can be supplemented with an internal grinding head. Process-optimised external and internal grinding heads are available for the LGG. In both external grinding heads, internal spindle balancing systems are employed. High drive power and speeds are great benefits, e.g. when used with new grinding material. Simple and fast replacement of the grinding pin is made possible by means of modern tool clamping. For...

Abrir o catálogo na página 3

Deviation-free topological grinding1 • Deviation free and twist-free grinding2 New technological possibilities1 • Superimposition of rolled end relief (GER: Generated End Relief)2 with conventional topological corrections • Constant profile crowning across whole effective tool area • Excitation-optimised edge corrections, NEO (Noise Excitation Optimized)2 - Free specification of amplitude, wavelength, phase and orientation - Superimposition of corrugation with conventional topological corrections • Asymmetric gearing • Beveloids 1 Standard planer can be used, no linear planing necessary 2...

Abrir o catálogo na página 4

Software/control technology The new, user-friendly LHGe@rTec® interface makes it much easier to operate the gear cutting machine and has many advantages for the operator: • Individual configuration • Intuitive operation • User guidance for process and change-over procedures • Mathematical analysis • Touch screen • Graphical input support • Incorporation of additional documentation (e.g. fixture layout, hob tool/arbor assembly, etc.) • Integrated webcam • Siemens 840 D Solutionline The Collision Control software package is available to minimise damage in the event of unexpected impact...

Abrir o catálogo na página 6

Palletizing Cell (LPC) Standardized transport containers with basket technology facilitate a uniform approach to logistics, as well as flexible future-oriented production. Plastic Chain Conveyor (KKB) The plastic chain conveyor is available in the standard version for workpieces up to 20 kg in weight and in the heavy duty version for workpieces up to 180 kg in weight, and is designed to transport any number of irregularly shaped workpieces without them coming into contact with each other. Robot Cell (LRC) Hook-ready robot solution in modular design replaces complex sorting systems,...

Abrir o catálogo na página 7

Machine Tools and Automation Systems from Liebherr System Solutions in the Area of Machine Tools Included in the production programme are gear hobbing machines, gear shaping machines and generating- and profile grinding-machines, all noted for their high degree of stability and availability. Particular importance is attached to the energy efficiency of the machines. Gear cutting machines from Liebherr are supplied to renowned manufacturers of gears and gearboxes and largescale slewing rings worldwide. They are in demand primarily from the automotive and construction machinery industries and...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos Liebherr Mischtechnik

-

Timber handling

36 Páginas

-

Opening up New Horizons

32 Páginas

-

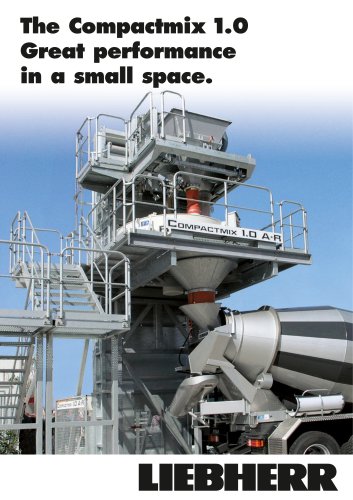

The Compactmix 1.0

12 Páginas

-

HTM 1205 T / LTB 12+4

2 Páginas

-

LTB

12 Páginas

-

70E Electric trailer concrete pump

4 Páginas

-

Ring-pan mixer

8 Páginas

-

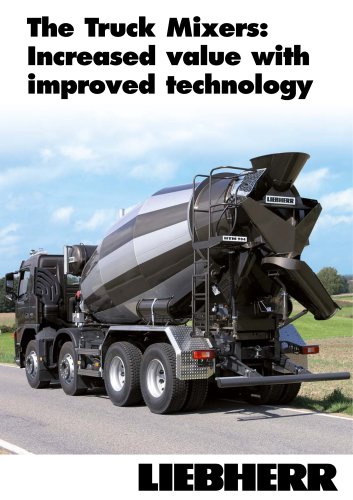

HTM 705 6 Truck mixer generation 05

16 Páginas

-

50 M5 XXT

4 Páginas

-

47 M5 XXT

4 Páginas

-

42 M5 XXT

4 Páginas

-

37 Z4 XXT

4 Páginas

-

36 XXT truck mounted concrete pump

16 Páginas

-

32 Z5 XXT

4 Páginas

-

Control Systems from Liebherr

12 Páginas

-

Mobile twin shaft Mixer

2 Páginas

-

Optimum Conveyance of Concrete

16 Páginas

-

24 M4 XH Truck mounted concrete pump

4 Páginas

-

LTM 1090-4.2

30 Páginas

-

LTM 1230-5.1

24 Páginas

-

Process monitoring ARTIS

4 Páginas

-

Gear shaping machines LS 200-500 F/E

8 Páginas

-

Gear shaping machine LS 180

4 Páginas

-

Gear hobbing machines LC 2000-16000

6 Páginas

-

Gear hobbing machines LC 600-2000

4 Páginas

-

Gear hobbing machines LC 200-500

8 Páginas

-

Gear hobbing machines LC 80-180

8 Páginas

-

Gear hobbing machines LC 60-130

8 Páginas

-

The ChamferCut process

4 Páginas

-

Flyer Betomat sectional view

1 Páginas

-

Jobreport Betomat

2 Páginas

-

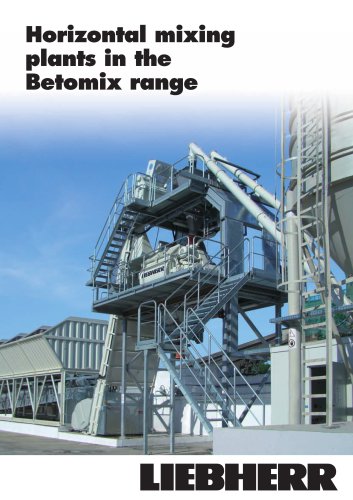

Brochure mixersystems

12 Páginas

-

Brochure truckmixer HTM 905

8 Páginas

-

DW 1.25 - 6.0

4 Páginas

-

Mobilmix 2.5

2 Páginas

-

Stationary Concrete Pumps

20 Páginas

-

Raupen- betonpumpe

4 Páginas

-

37 R4 ST

4 Páginas