Automatic Pressure Sensitive Labeling’sFlexibility Lowers Operating Costs and Increases Productivity

1 /

6Páginas

Excertos do catálogo

ҩ Label-Aire, Inc., an Impaxxή company.All Rights Reserved. >

Abrir o catálogo na página 1

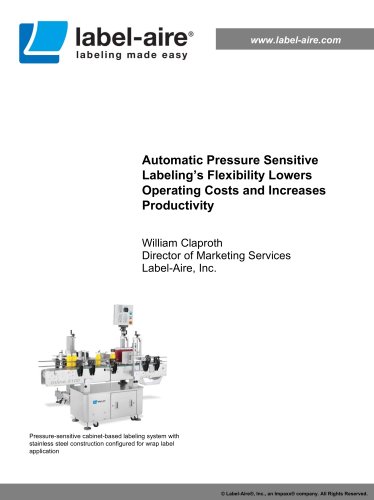

Automatic labeling systems afford companies the ability to implement a flexible system that can adjust to demand levelsand thus meet changing market needsefficiently without increasing manpower requirements. In addition, automatic labeling systems can be designed in a product specific configuration as an inexpensivealternative for high speed/high volume requirements. In both cases, automaticsystems provide consistent product labeling,ensuring that products are aestheticallypleasing and convey an image of high quality. Throughput is increased when automatic labeling systems are designed with...

Abrir o catálogo na página 3

Streamline changeovers With available tool-less adjustments for products of different diameters and extensive memory capacity in the label applicators software, automatic pressure sensitive labeling systems make it easy to changeover from product to product.These streamlined changeovers eliminate the costs, labor requirements, waste, and downtime inherent in hand or semi-automatic labeling. > Labeling system configured for ғzero down timeprevents stoppages in labeling throughput Auto splice dual unwinderallows non-stop labeling Application-specific challenges Automatic pressure sensitive...

Abrir o catálogo na página 4

Reordering new labels to work with a standard front/back labeling system (two applicators, one for the front-and the other applicator for the back labels)would have cost the customer close to six figures. The solution was to implement a labeling system with a single head and a vacuum wrap belt. As the product sensor detects a bottle on the conveyor, properly-spaced front andback labels are dispensed onto the vacuum wrap belt and applied to the spinning bottles accurately to within +/-1/32" (.8 mm) maintaining properorientation. The result was accurately labeled bottles at speeds of up to 60...

Abrir o catálogo na página 5Todos os catálogos e folhetos técnicos Label Aire

-

3114TS

2 Páginas

-

3111TS

2 Páginas

-

IL 6000 Wrap

1 Páginas

-

Inline 6000 Wrap (Oblong & Round)

1 Páginas

-

Print and Apply Full Line Fold Out

2 Páginas

-

3155 Wipe On

2 Páginas

-

3135

2 Páginas

-

Applicator stand

2 Páginas

-

Primary Applicator Full Line Foldout

2 Páginas

-

Inline 6000 Front/Back Zero Downtime

1 Páginas

-

Labeling System Full Line Foldout

2 Páginas

-

3125 Wipe-On

2 Páginas

-

3115 Wipe-On

2 Páginas

-

3111 Air-Blow

2 Páginas

-

Inline Series 6000-N

4 Páginas

-

6115 With Orienting Wrap

1 Páginas

-

2139/3115 Pallet Labeler

1 Páginas

-

2114M Tamp-Blow System

1 Páginas

-

2138 Print & Apply System

1 Páginas

-

Print & Apply Full Line Foldout

2 Páginas

-

3138-N Printer Applicator

2 Páginas

-

2038 Printer Applicator

2 Páginas

-

3139/15 Wipe-On Primary Applicator

2 Páginas

-

3114 Tamp-Blow

4 Páginas

-

3114-NV Tamp-Blow

2 Páginas

-

2111/14 EAS

2 Páginas

-

3015ND Wipe On

2 Páginas

-

2114 Tamp-Blow

2 Páginas

-

2111 High Speed

2 Páginas

-

2111 Air-Blow

2 Páginas

-

3115 Hugger Belt System

1 Páginas

-

2172 Hugger Belt System

1 Páginas

-

6114 Loose Loop Printer Applicator

1 Páginas

-

3-Panel DVD Case Labeling System

1 Páginas

-

Continuous Belt Conveyor

1 Páginas

-

3138-NV Printer Applicator

2 Páginas

-

3139/38-N Printer Applicator

2 Páginas

-

3111 HS

2 Páginas

-

3111-NV Air-Blow

2 Páginas

-

Rotary Series 9000

4 Páginas

-

3-Panel CD Case Labeling System

1 Páginas

-

6200 Inline Series

2 Páginas

-

5100 Inline Series

2 Páginas

-

3114 DAT

2 Páginas

-

3115-NV Wipe-On

2 Páginas

-

3138-N Merge Printer Applicator

2 Páginas

-

3138-N RFID Printer Applicator

1 Páginas

-

2139 RFID Printer Applicator

1 Páginas

-

5115 HSWA Bottle Labeler

2 Páginas

-

3038 Printer Applicator

2 Páginas

-

2100 Series Full Line Foldout

2 Páginas

-

2115 Wipe-On

2 Páginas

-

Labeling System Full Line Foldout

2 Páginas

-

Inline Series 9000

4 Páginas

Catálogos arquivados

-

Applicator Stands

2 Páginas