Website:

Keller ITS (Infrared Temperature Solutions)

Website:

Keller ITS (Infrared Temperature Solutions)

Grupo: Legris Industries

Excertos do catálogo

TECHNICAL REPORTS Emissivity: Definition and Influence in Non-contact Temperature Measurement by Albert Book In non-contact temperature measurement, a pyrometer detects the thermal energy or The amount of infrared/thermal energy an object will radiate is infrared radiation emitted by an object. from not only a function of temperature, but depends on the material this detected radiation, the pyrometer calculates the temperature according to Planck’s radiation law. The amount of energy emitted itself. Emissivity describes a material’s ability to emit or release the thermal energy which it has absorbed. A perfect radiator – known as a ‘black body’ – will emit the entire amount of absorbed energy. A real body will always emit less energy than by the object largely depends on the emis- a black body at the same temperature. Emissivity ε is the ratio of infrared radiation emitted of a given object (real body) Φr and a black body Φb at the same temperature. But what exactly do we mean when we refer to emissivity, and how will it influence the temperature measurement? How can we determine the amount of emissivity, and what does it depend on? What kind of tempera- Thus, emissivity is a nondimensional quantity or factor between 0 and 1, or between 0 and 100%. ture reading errors might occur due to an incorrect emissivity setting and how can one prevent measuring errors? This article discusses these and other questions about emissivity. transmitted background radiation target object reected ambient radiation Fig. 1 Composition of radiation received by the pyrometer’s sensor. Atmospheric radiation which reaches a measurement object is reflected more or less strong, depending on the material’s reflectivity. The same laws of radiation which govern visible light also apply to thermal energy. In the case of transparent objects such as glass or plastic foil, additional thermal energy from below the object’s surface or from the background might contribute to the radiation detected. Transmissivity describes the percentage of radiation which

Abrir o catálogo na página 1

an object. The total amount of radiation detected by a pyrometer’s sensor is the sum of several components, as shown in the following equation. O = £ * O + P * O + T * O I obj amb back Oobj = Radiation from target object Oamb= Ambient radiation (foreground) O i = Radiation from background back The radiation coefficients are linked together in the equation: 1 = £ + p + T There will be no transmission of radiation through opaque objects; thus the transmissivity factor will not be applicable. 1 = £ + p Factors which influence emissivity The emissivity of an object depends...

Abrir o catálogo na página 2

TECHNICAL REPORTS were to adjust the pyrometer for the theoretical emissivity value drawn from literature, the displayed temperature reading will be erroneously high. To obtain an accurate temperature reading, the user will have to adjust the pyrometer for a somewhat higher emissivity than declared. We could call this a simulated increase in emissivity. Through a comparison measurement using a contact thermometer we can establish the actual emissivity of an object and ad- Vergleichsstrahler Messobjekt just the pyrometer accordingly, provided that the contact thermometer measurement is very...

Abrir o catálogo na página 3

TECHNICAL REPORTS ments is based on a visual colour comparison at a wavelength In particularly unfavourable or complex measuring conditions, it is recommendable to consider both the two spectral temperature values as well as the temperature reading based on the This method’s effectiveness is not dependent on the size of two-colour ratio. Depending on the result, the user can select the target object. The chart Fig. 4 demonstrates the effect of an the method which is best suited for his application and adjust incorrect pyrometer adjustment or a change in emissivity. Two-colour pyrometers...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos Keller ITS (Infrared Temperature Solutions)

-

AN CellaAsphalt_ID2523_201504_en

4 Páginas

-

AN Concrete Mixers_ID2522_201606_en

4 Páginas

-

BR CellaTemp PX_ID2007_202312_en

20 Páginas

-

BR CellaTemp PA_ID2004_202403_en

20 Páginas

-

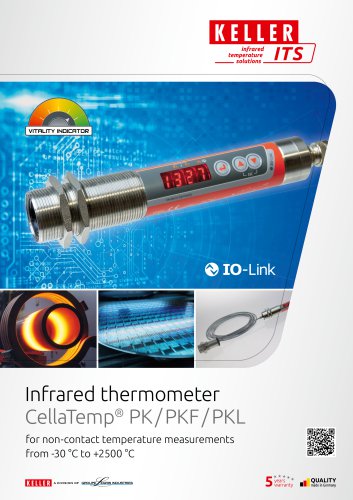

BR CellaTemp PK PKF PKL_ID2005_202411_en

16 Páginas

-

AN Coking plant_ID2538_202407_en

4 Páginas

-

AN CellaCombustion_ID2520_202411_en

4 Páginas

-

KITS App - Digital Service

6 Páginas

-

AN Aluminium_ID2521_202208_en

4 Páginas

-

AN Roller stand_ID2530_202203_en

4 Páginas

-

AN Furnace_ID2529_202201_en

4 Páginas

-

AN_Bar mill_ID2533_202202_en

4 Páginas

-

AN CellaWire_ID2531_202110_en

4 Páginas

-

Software CellaView

8 Páginas

-

High-tech solutions from tradition

20 Páginas

-

BR CellaCast PA83 PT183_201811_en

12 Páginas

-

BR CellaPort PT_201905_en

16 Páginas

-

AN CellaCast_201811_en

8 Páginas

-

Flyer IO-Link_201810_en

2 Páginas

-

TR Induction heating_201303_en

6 Páginas

-

TR Panorama-Pyrometer_201508_de

5 Páginas

-

TR Metrological Errors_201604_en

3 Páginas

-

TR IO-Link_201610_en

7 Páginas

-

BR Mikro PV 11_201512_en

4 Páginas

-

TR Optical Influences_201609_en

4 Páginas

-

TR Two-colour pyrometer_201507_en

8 Páginas

-

AN CellaInduction_201604_en

4 Páginas

-

AN Glued laminated timber_201606_en

4 Páginas

-

AN Metal sheets_201608_en

4 Páginas

-

AN Measurement of small objects

4 Páginas