Website:

KEB Automation KG

Website:

KEB Automation KG

Grupo: KEB

Excertos do catálogo

SERVO GEARED MOTORS EN

Abrir o catálogo na página 1

CONTROL & AUTOMATION DRIVES MOTORS & GEARS NETWORK OF AUTOMATION BRAKES & CLUTCHES Portfolio Solutions Technical characteristics Product Overview Software KEB DRIVE Drive selection Selection table Electrical Connection Encoder system Brakes Servo Geared Motors Dimensions 2

Abrir o catálogo na página 2

PORTFOLIO Automation with drive Support and reinforcement – this is what the term "servo" stands for. KEB takes up exactly here and offers a strong "helper" with the permanent magnet synchronous motors of the TA series. With their compact dimensions and high dynamic torques, the TA servomotors are particularly suitable for precise positioning and powerful driving. As a important component, they fit into varius applications with the highest efficiency and variety of uses. HELICAL GEAR: the classic type, with high power density and a wide range of gear ratio up to 13,600 Nm MOTOR: TA servo...

Abrir o catálogo na página 3

SOLUTIONS FOR MACHINES AND PLANTS WOODWORKING Core applications in woodworking machines involve edge and surface processing, drilling and milling technology, and assembly systems as well as the COMPLETE MACHINING AND PROCESSING of solid wood. VISUALISATION METALWORKING Metal processing requires stable drives for robust machines, POWERFUL COMPONENTS FOR DYNAMIC MOVEMENTS, as an auxiliary unit or main drive. KEB System of Gearmotors serves exactly this target area. PLASTICS TECHNOLOGY PRECISION, PERFORMANCE AND QUALITY – the strength of the KEB systems are shown especially on plastic...

Abrir o catálogo na página 4

INTRALOGISTICS Conveying, transporting and lifting for CONTINUOUS AND CYCLICAL PROCESSES. Applications with the highest variance and diverse support are in the KEB portfolio. THEATER TECHNOLOGY The theater and stage area require PRECISION AND SAFETY – our motors and gears provide this for a perfect performance. MEDICAL SYSTEMS EFFICIENT, PRECISE DRIVE SOLUTIONS in medical technology help in diagnostics treating patients more gently. FOOD & BEVERAGE PROCESSING High degree of protection, durable corrosion protection, smooth surfaces and few undercut elements - suitable for the food industry....

Abrir o catálogo na página 5

TECHNICAL CHARACTERISTICS TA SERIES Permanent synchronous servomotors, optimised as a drive system in combination with the COMBIVERT drive controller. Standard version: • Protection standard IP54 • Temperature class 155°C • PTC thermistor sensor • Nominal voltage Un=400 V or Un=230 V • Number of poles: 6-pole The motors correspond to the following standards: • DIN EN 60034 Rotating electrical machines, rating and performance • DIN 42948 Mounting flanges for electrical machines The type designation for gear units / motors describes the construction of the unit starting from the output side....

Abrir o catálogo na página 6

PRODUCT OVERVIEW SERVO MOTOR WITH SELF COOLING T0 [Nm] SERVO MOTOR WITH FORCED VENTILATION MOTOR Tmax Maximum torque

Abrir o catálogo na página 7

SOFTWARE KEB-DRIVE SYSTEM BUILDER TECHNICAL INFORMATION CONVENIENT SELECTION Put together the suitable drive package quickly, make the selection of prepared options, this is exactly what the KEB DRIVE configuration software offers and much more ... • Detailed product descriptions with data tables • 2D drawings and 3D models • Universal search with direct product suggestions • Hardware and software components for system building Motor / DRIVE CONTROLLER • Direct export functions, e.g. into the ERP-system Load KEB DRIVE and immediately call up the advantages of the configuration software for...

Abrir o catálogo na página 8

CONFIGURATION DESCRIPTION STEP: 3-dimensional model in STEP-format RTF: Saves dimension sheet in RTF-format to clipboard Fast configuration and selection of KEB gearboxes and motors Exact description and data available IMMEDIATELY 2D and 3D geometric data can be called up directly System building with further KEB components Download product selection software for KEB Gears & Motors: www.keb-drive.

Abrir o catálogo na página 9

DRIVE SELECTION NOMINAL TORQUE Tn The values given in the tables are valid for the following conditions: • Duty cycle S1 • Maximum ambient temperature +40° C -θ Tth = Tn * 145°C 105°C Reduced motor torque at ambient temperature 40° C < θ ≤ 80° C: Installation altitude up to 1000m above mean sea level SELECTION CONDITIONS AT PERIODICAL LOAD Ta= Tamax = max(Tai )≤ Tmax Nominal torque Servo motor Maximum torque Servo motor Actual average load torque Maximum load torque Load torque of cycle i Duration of cycle i Total time t = ti RADIAL FORCE ON OUTPUT SHAFT 2000 ab * Fr =T * fz d0...

Abrir o catálogo na página 10

RADIAL FORCES PERMISSIBLE RADIAL FORCES FOR THE OUTPUT SHAFT If there are radial loads on the output shaft, they should be compared with the permissible values for radial forces. The values in the table for the permissible radial forces apply under the following conditions: • constant load in continuous operation • no axial forces FR1[N] Output shaft d * l [mm] If the radial force is not applied to the middle of the shaft, use the following formula for the conversion of the permissible radial force: F Rx1 = F R1 ∗ permissible radial force for bearing lifetime application at middle of output...

Abrir o catálogo na página 11

SELECTION TABLE SERVO MOTOR WITH SELF COOLING MOTOR Imax R_u-v L_u-v kEpk V [A] [Ω] [mH] [mV*min]

Abrir o catálogo na página 12

Nominal speed Stall torque Nominal torque S1 Maximum torque Weight Inertia Type of motor winding Current at stall torque Current at maximum torque R_u-v Winding resistance L_u-v Winding inductance kEpk Voltage constant, Peak value mV*min = V/(1000 1/min) Effective value kE=kEpk/√2 nmax Maximum speed n≤2000 1/min → nmax=3000 1/min n=3000 1/min → nmax=4500 1/min n≤6000 1/min → nmax=6000 1/min 1 - Characteristic curve for S1-duty cycle 2 - Voltage limit curve 400 V

Abrir o catálogo na página 13

SELECTION TABLE SERVO MOTOR WITH FORCED VENTILATION MOTOR Imax R_u-v L_u-v kEpk V [A] [Ω] [mH] [mV*min]

Abrir o catálogo na página 14

ELECTRICAL CONNECTION MOTOR TA2 ... TA5 Power connector size 1, 8pole Optional: TA1 ... TA5 – Counterplug 00EKQS2-0002 MOTOR TA6 Power connector size 1.5, 8pole Optional: TA6 – Counterplug 00EKQS2-0001 F – FORCED VENTILATION Power connector 4pole, Counterplug included Voltage/Frequency: 3 ~ 400 V 50 Hz Rated current of forced ventilation: 0.14 A SUITABLE COMPONENTS For the simple connection of the TA motors to the drive controller COMBIVERT S6 / F6, the following pre-assembled motor cables for the limited flexible installation are available: TA1 ... TA5: power cable SpeedTec size 1 / M23...

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos KEB Automation KG

-

NOA - AUTOMATION & IIOT PLATFORM

6 Páginas

-

HIGH TORQUE SERIES DL4 SERVO SYSTEMS

7 Páginas

-

COMBIVERT P6

16 Páginas

-

COMBIVERT T6

4 Páginas

-

C6 COMPACT 3

4 Páginas

-

CONTROL AND AUTOMATION

264 Páginas

-

SOLUTION SERVO PUMP

8 Páginas

-

CNC SOLUTIONS

6 Páginas

-

EMC COMBILINE

32 Páginas

-

DL3 Servo Motors

16 Páginas

-

COMBIVERT G6

16 Páginas

-

COMBIVERT R6

8 Páginas

-

SYSTEM FOR SAFETY

12 Páginas

-

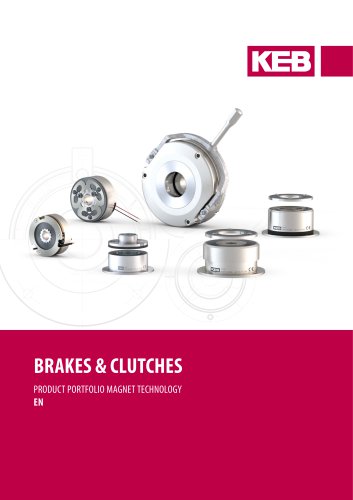

BRAKES & CLUTCHES

40 Páginas

-

PORTFOLIO

8 Páginas

-

COMBIVERT S6

24 Páginas

-

COMBIVERT F6

18 Páginas