Excertos do catálogo

KAWASAKI HEAVY INDUSTRIES, LTD. ROBOT DIVISION http://www.khi.co.jp/robot/ Tokyo Head Office/Robot Division 1-14-5 Kaigan, Minato-ku, Tokyo 105-8315, Japan Phone: +81-3-3435-6852 Fax: +81-3-3437-9880 Akashi Works/Robot Division 1-1, Kawasaki-cho, Akashi, Hyogo 673-8666, Japan Phone: +81-78-921-2946 Fax: +81-78-923-6548 Kawasaki Robotics (U.S.A.), Inc. www.kawasakirobot.com 28140 Lakeview Drive, Wixom, MI 48393, U.S.A. Phone: +1-248-446-4100 Fax: +1-248-446-4200 Kawasaki Robotics (UK) Ltd. www.kawasakirobot.co.uk/ Unit 4 Easter Court, Europa Boulevard, Westbrook Warrington Cheshire, WA5 7ZB, United Kingdom Phone: +44-1925-71-3000 Fax: +44-1925-71-3001 Kawasaki Robotics GmbH www.kawasakirobot.de 29 Sperberweg, 41468 Neuss, Germany Phone: +49-2131-34260 Fax: +49-2131-3426-22 Kawasaki Machine Systems Korea, Ltd. www.kawasakirobot.co.kr 69BL-1LT, 638, Gojan-Dong, Namdong-Gu, Incheon, 405-817, Korea Phone: +82-32-821-6941 Fax: +82-32-821-6947 Kawasaki Robotics (Tianjin) Co., Ltd. www.kawasakirobot.cn Bldg 3, No.16, Xiang'an Road, TEDA, Tianjin 300457 China Phone: +86-22-5983-1888 Fax: +86-22-5983-1889 Kawasaki Robot CAUTIONS TO BE TAKEN TO ENSURE SAFETY • For those persons involved with the operation / service of your system, including Kawasaki Robot, they must strictly observe all safety regulations at all times. They should carefully read the Manuals and other related safety documents. • Products described in this catalogue are general industrial robots. Therefore, if a customer wishes to use the Robot for special purposes, which might endanger operators or if the Robot has any problems, please contact us. We will be pleased to help you. • Be careful as Photographs illustrated in this catalogue are frequently taken after removing safety fences and other safety devices stipulated in the safety regulations from the Robot operation system. ISO certified in Akashi Works. Kawasaki Motors Enterprise (Thailand) Co., Ltd. (ROBOT DIVISION) www.khi.co.jp/robot/th/ 129 Rama 9 Road, Kwaeng Huay-Kwang, Khet Huay-Kwang, Bangkok 10310, Thailand Phone: +66-2-247-7935-8 Fax: +66-2-247-7934 * Materials and specifications are subject to change without notice.

Abrir o catálogo na página 1

There are a number of issues involved in implementing and leveraging robot systems. In addition to requiring a high level of knowledge and expertise, a large amount of time must be set aside for robot teaching. “KCONG”, the automatic robot teaching software offered by Kawasaki, effectively eliminates these issues. Using 3D CAD data of work-pieces, KCONG automatically creates robot operation programs that radically improve the efficiency of robots and make them more economical. This software significantly reduces the time needed for robot teaching and lowers production costs. Features Easy...

Abrir o catálogo na página 2

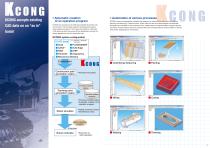

KCONG accepts existing CAD data on an “as is” basis! • Automatic creation of an operation program KCONG can accept any 3D CAD data available for general use and convert it into the data needed to automatically create a robot operation program. This makes it possible to implement CAD data and robot environments that seamlessly connect the design department with the production site. • Automation of various processes KCONG comes with application software that supports a variety of functions, such as welding, painting, and deburring. These functions, which make full use of the technologies and...

Abrir o catálogo na página 3

• Easy operation for first-time users Easy operation significantly boosts productivity! KCONG features an intuitive graphical user interface (GUI). Using this GUI, first-time users can quickly begin working with KCONG shortly after it is installed, with no need for any special training. KCONG operation screens ■ Work-piece Shape Design ■ Automatic creation of operation programs (teaching points) ■ Editing teaching points For KCONG users already have a 3D CAD system, data from the system can be accepted as-is. (In some cases, prior verification may be required for data conversion.) KCONG...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos Kawasaki Robotics GmbH

-

B Series Spot welding robots

6 Páginas

-

Line Up Kawasaki Robot with Options

15 Páginas

-

Lineup Overview

2 Páginas

-

K-ROSET Offline programming tool

4 Páginas

-

MS005N

2 Páginas

-

Kawasaki Robot K series

12 Páginas

-

Kawasaki Robot Y series

6 Páginas

-

Kawasaki Vision System

2 Páginas

-

Palletizing robots

6 Páginas

-

MC series

2 Páginas

-

Dual-arm SCARA Robot “duAro”

6 Páginas

-

F60 Controller

2 Páginas

-

Controllers

1 Páginas

-

Kawasaki CX Series robots

4 Páginas

-

Clean Robot NTS, TTS series

2 Páginas

-

Kawasaki Robot Arc welding robots

6 Páginas

-

Kawasaki Robot duAro 2

2 Páginas

Catálogos arquivados

-

Controller

1 Páginas

-

Kawasaki Vision System

2 Páginas

-

K-SPARC PALLETIZING SOFTWARE

2 Páginas

-

MC004N

5 Páginas

-

Kawasaki Dual Arm Scara

2 Páginas

-

Kawasaki Clean robots

6 Páginas

-

Kawasaki B Series robots

6 Páginas

-

M-Series

5 Páginas

-

Z-Series

7 Páginas

-

CX series

2 Páginas

-

R-Series

7 Páginas

-

Lineup

8 Páginas

-

MC/MS-Series

5 Páginas

-

Overview

2 Páginas

-

K-Roset

4 Páginas

-

Cubic-S

3 Páginas

-

Palletizer

5 Páginas

-

Y-Series

5 Páginas

-

RA-Series

5 Páginas

-

RS80N

2 Páginas

-

RS50N

2 Páginas

-

RS30N

2 Páginas

-

RS20N

2 Páginas

-

RS10L

2 Páginas

-

RS10N

2 Páginas

-

RS06L

2 Páginas

-

RS05L

2 Páginas

-

RS05N

2 Páginas

-

RS03N

2 Páginas

-

RS15X

2 Páginas

-

Metal Fabrication Automation

4 Páginas

-

FSJ

4 Páginas

-

PC Roset

2 Páginas

-

Y Series

6 Páginas

-

Z-Series

8 Páginas

-

R series

8 Páginas

-

E controller

2 Páginas

-

D-Controller

6 Páginas

-

EDU Pack

2 Páginas

-

NS/TLTS/FC Series Clean Room- robots

6 Páginas

-

FD/ZD/MD Series Palletizer

4 Páginas

-

Image Catalogue

5 Páginas

-

Line up

8 Páginas