Excertos do catálogo

What you should know about Ipsen’s atmosphere technology. Hard work wins

Abrir o catálogo na página 1

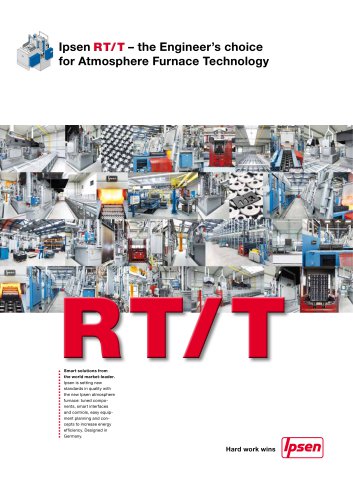

How is such an atmosphere furnace constructed and why in this way and not another? The following requirements were all important in the development of the design: First – uniform heat transfer to the charge and protection against direct heat radiation. Second – a uniform flow of the furnace atmosphere through the charge. Third – problem free operation and long furnace service life. For the latter the most important factor is the characteristics of the furnace interior. The bricklining comprises insulating firebricks, which are suitable for temperatures well above the working temperature and...

Abrir o catálogo na página 2

Carburisation, carbon nitriding, bright hardening and carbon-free bright annealing in multi-purpose chamber furnaces take place in carbon contentregulated atmospheres – for bright tempering in tempering furnaces, no controlled atmospheres are required. The following gassing processes are particularly important in the above: Supercarb® air direct gassing, Endogas gassing and nitrogen-methanol gassing. The proven Ipsen Supercarb® process is remarkable for its high efficiency and quick, uniform and reproducible carbon transfer. It works at heat treatment temperatures above 850 ºC. In the...

Abrir o catálogo na página 3

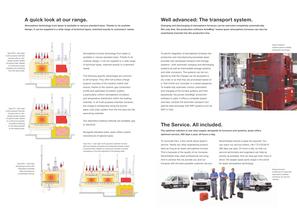

Ipsen transport systems ensure reliable production processes Well advanced: The transport system. Charging and discharging of atmosphere furnaces can be executed completely automatically. Not only that, the production software AutoMag® means Ipsen atmosphere furnaces can also be seamlessly inserted into the production line. To permit integration of atmosphere furnaces into production and manufacturing processes Ipsen provides fully developed transport and storage systems – both automatic charging and discharging systems as well as intermediate storage systems and roller conveyors. The...

Abrir o catálogo na página 4

Hard work wins For over 60 years Ipsen has been finding new ways of producing steel of ever improving quality using the company’s innovative, proprietary technologies, such as the AvaC® process (low-pressure carburising), the SolNit® process (solution nitriding) and the recently developed HybridCarb process (gas carburising with recycling). Ipsen’s offerings combine the highest performance with outstanding reliability, which perhaps explains why our furnaces and heat treatment equipment enjoy an excellent reputation all over the world. Our customers work in automotive, aviation and...

Abrir o catálogo na página 5Todos os catálogos e folhetos técnicos Ipsen International GmbH

-

IP-704 Fluid

2 Páginas

-

Ipsen Plant Technology

7 Páginas

-

Ipsen HydroNit Sensor

2 Páginas

-

Ipsen Brazing

2 Páginas

-

Ipsen Titan

9 Páginas

-

Ipsen HybridCarb

3 Páginas

-

Ipsen AutoMag® 4.0

3 Páginas

Catálogos arquivados

-

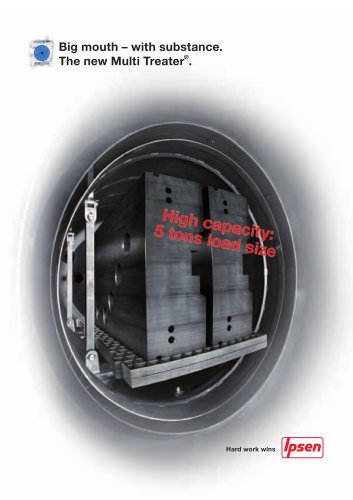

Ipsen Multi Treater

5 Páginas

-

Carb-o-Prof® 4.0

3 Páginas

-

Ipsen SolNit

3 Páginas

-

Ipsen Turbo²Treater

6 Páginas

-

Wind Energy

5 Páginas

-

Ipsen Vacuum Technology

6 Páginas

-

Ipsen - We deliver performance

5 Páginas

-

Ipsen SuperQuench

3 Páginas