Excertos do catálogo

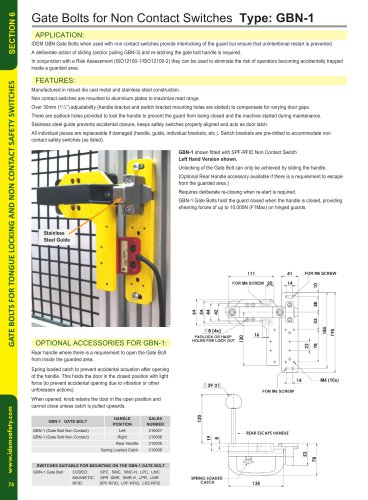

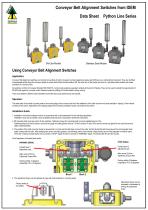

Conveyor Belt Alignment Switches from IDEM Data Sheet Die-Cast Models Python Line Series Stainless Steel Models Using Conveyor Belt Alignment Switches Application: Conveyor Belt Alignment switches are mounted on sections of plant conveyors to protect against excessive belt drift due to an unintentional movement. They can be fitted at appropriate points along the conveyor length to ensure that should the belt position drift, the roller arm of the switch will move to a pre-determined position and cause activation of a control circuit. All switches conform to European Standard IEC 60947-5-1 and provide positively operated contacts at the point of tripping. They can be used to satisfy the requirements of EN 620 with regard to conveyor control hazards caused by shifting of the belt position during running. They are available in different roller diameters to provide heavy duty performance and long life. Operation: The steel roller of the switch is placed near to the running edge of the conveyor belt such that deflection of the roller and arm will cause activation “tripping” of the internal contacts of the switch. Adjustment of the tripping angles and necessary activation torque is provided by the switch. Installation Guide: 1. Installation of all switch systems must be in accordance with a risk assessment for the individual application. Installation must only be carried out by competent personnel and in accordance with these instructions. 2. M5 mounting bolts must be used to fix the switches. Tightening torque for mounting bolts to ensure reliable fixing is 4 Nm. Tightening torque for the lid screws, conduit entry plugs and cable glands must be 1.5 Nm to ensure IP seal. Only use the correct size gland for the conduit entry and cable outside diameter. 3. The position of the roller must be chosen to ensure that in normal use the belt does not touch the roller, but that should the belt move beyond its normal guides it will make contact with the roller. After selecting the correct mounting position, the switching points of the internal contact blocks can be finely adjusted via internal cams. There are 2 internal contact blocks one to provide a “STOP” signal the other to provide a “WARNING” signal. The blocks offer NC and NO circuits. Final Adjustment of contact block action: WARNING SIGNAL STOP SIGNAL Contact block 1 Adjustment cam. Contact block 2 Adjustment cam. Allen screw (2.5mm) Tightening Torque 2Nm Allen screw (2.5mm) Tightening Torque 2Nm Factory setting 14 degrees (Adjustable 10 to 18 degrees) Factory setting 25 degrees. (Adjustable 15 to 35 degrees) 4. The operational torque can be adjusted to cope with belt sensitivity or mounting angle. Factory setting is low setting Operational torque can be increased or decreased by turning the adjustme

Abrir o catálogo na página 1

Maintenance: Every month: Check correct operation at all switch locations along all coverage length. Check for nominal warning and trip angle, re-set if necessary. Every 6 months: Isolate power and remove cover. Check screw terminal tightness and check for signs of moisture ingress. Never attempt to repair any switch. Contact operation/Deflection of roller. (Factory settings shown.) 0 Degrees 14 Degrees 25 Degrees 65 Degrees WARNING STOP Wiring examples (standard version) LED Flashing Red or Steady Green (Bi-colour) When power is applied to the Red wire, the lamp will illuminate Red...

Abrir o catálogo na página 2

MEDIUM DUTY STAINLESS STEEL Belt Switch SS- 35mm Short Roller (Stainless Steel)

Abrir o catálogo na página 6

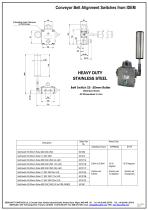

HEAVY DUTY STAINLESS STEEL Belt Switch SS- 35mm Long Roller (Stainless Steel)

Abrir o catálogo na página 7

HEAVY DUTY STAINLESS STEEL Belt Switch SS- 50mm Roller (Stainless Steel) All Dimensions in mm IDEM SAFETY SWITCHES Ltd., 2 Ormside Close, Hindley Industrial Estate, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076 IDEM (USA) 4416 Technology Drive, Fremont, CA 94538 Tel:510-445-0751 Fax:1866-431-7064 email: sales@idemsafety.com Web: www.idemsafety.com

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos Idem Safety Switches

-

HS-SS-Z and HSM-Z

2 Páginas

-

RAMZSense LPZ

2 Páginas

-

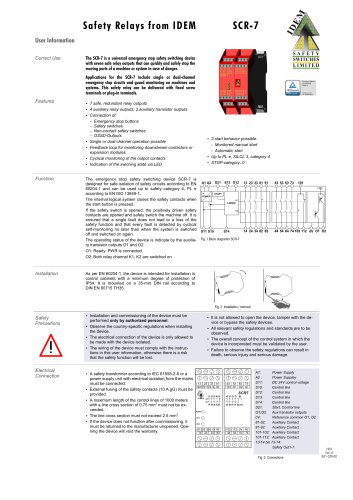

SCR-7

4 Páginas

-

Guardian Line Series

4 Páginas

-

MICRO SWITCHES

4 Páginas

-

KLM-Z-4ST

2 Páginas

-

K-15 & K-15-SS: Tongue Switches

2 Páginas

-

KM: Interlock Tongue Safety Switch

2 Páginas

-

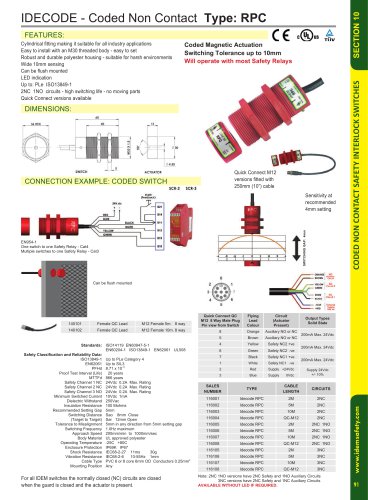

CPC: Coded Non Contact IDECODE

1 Páginas

-

SPC: Coded Non Contact IDECODE

1 Páginas

-

LPC: Coded Non Contact EUROCODE

1 Páginas

-

WPC: Coded Non Contact IDECODE

1 Páginas

-

MPC: Coded Non Contact IDECODE

1 Páginas

-

KPC: Coded Non Contact KOBRACODE

1 Páginas

-

GLS-SS

1 Páginas

-

LPR (with Integral LED)

1 Páginas

-

RPC

1 Páginas

-

INCH-3

1 Páginas

-

RAMZLOCK KLTM-RFID

4 Páginas

-

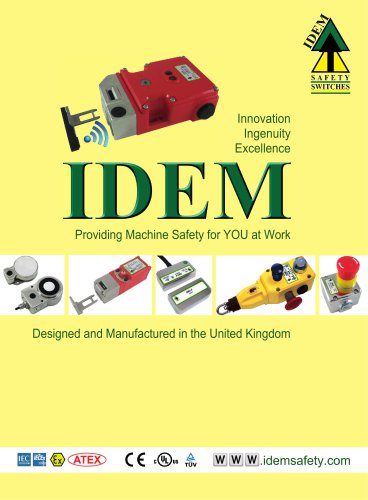

IDEM Shortform Catalogue 2014

8 Páginas

-

IDEM 2012 PRODUCT CATALOGUE

152 Páginas

Catálogos arquivados

-

2008 Main Catalogue

56 Páginas