Website:

Haskel

Website:

Haskel

Grupo: Ingersoll Rand

Excertos do catálogo

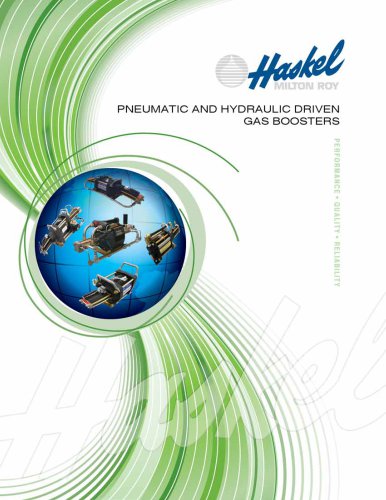

Pressure on Demand Pneumatic and Hydraulic Driven Gas Boosters

Abrir o catálogo na página 1

Why Use a Haskel Gas Booster Haske pneumatic and hydraulic driven gas boosters offer a flexible and efficient source for delivering high pressure gases. Oxygen or High Purity Cleaning: Haskel boosters are noted for their cleanliness and can handle pure gases such as oxygen without risk of any contamination. (Special cleaning required – advise factory.) Haskel’s oxygen cleaned products are certified per Mil Spec 1330. Refer to the Knowledge Library Link on the Haskel website, www.haskel.com, for the Oxygen Usage - Best Practice Guide. Multi-Staging Capability: For higher flow rates and...

Abrir o catálogo na página 2

Introduction to Pneumatic Driven Gas Boosters Theory of Operation Haskel Gas Boosters consist of a large area reciprocating air drive piston directly coupled by a connecting rod to a small area gas piston. The gas piston operates in a high pressure gas barrel section. Each gas barrel end cap contains high pressure inlet and outlet check valves. Varying applications require many different booster and horse power (HP) combinations. Haskel can assist with HP and Cooling requirements and provide circuitry assistance on the following issues: PID Control review and advisement, electrical control,...

Abrir o catálogo na página 3

Pneumatic Driven Gas Booster Configurations Single acting, single stage boosters are the smallest and lightest with pressures to 39,000 psi. Double acting, single stage provides twice the delivery of a single acting single stage booster. Two stage models are used for high gas compression ratios. Model AG Single Stage, Single Acting, Flow Thru Piston Model AG Single Stage, Single Acting Model AGD Single Stage, Double Acting, Cooling Fins Model AGD-4 (only) Single Stage, Double Acting, Cooling Jacket Model AGD Single Stage, Double Acting, Cooling Jackets Multi stage - Two boosters. More than...

Abrir o catálogo na página 4

Selecting a Pneumatic Driven Gas Booster means of boosting pressure for testing or small components and similar applications where volume is small and efficiency is not important. Control of maximum outlet pressure is accomplished with the use of an air drive pressure regulator. Maximum outlet pressure is drive area ratio multiplied by air pressure. Air driven gas boosters have seven significant operating parameters that determine their selection for any application. These are as follows: 1. Maximum discharge pressure? 2. Flowrate a. Is it constant? i. What is flowrate required? b. Is it...

Abrir o catálogo na página 5

Model Selection Chart Model Number Maximum Rated Gas Supply LEGEND: Ps = Gas Supply Pressure, Pa = Drive Pressure, Po = Outlet Pressure Maximum Rated Gas Outlet Static Piston Outlet Stall Displacement Pressure Per Cycle Formula Single Acting Single Stage Model AG Inlet Port 3/4” NPT Outlet Port 1/2” NPT Inlet Port: 3/8” NPT Outlet Port: 3/8” NPT 2 ea./ inlet & outlet Double Acting Single Stage Model AGD Interchangeable 3-3/8”SAE or 1/4”- H/P (BuTech) Both Ports Inlet Port: 3/8” NPT Outlet Port: 3/8” NPT Interchangeable 3-3/8”SAE or 1/4”-H/P both Ports. 2 ea. inlet & outlet Interchangeable...

Abrir o catálogo na página 6

Model Number Maximum Rated Gas Supply PSIG Maximum Rated Gas Outlet Inert Gas Static Outlet Piston Stall Pressure Displacement Formula Per Cycle Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both Ports Interchangeable 3-3/8”SAE or 1/4”- H/P (BuTech) Both Ports Interchangeable 3-3/8”SAE or 1/4”- H/P (BuTech) Both Ports Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both Ports Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both Ports Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both Ports Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both Ports Interchangeable 3/8”SAE or 1/4” H/P (BuTech) Both...

Abrir o catálogo na página 7

Sample Gas Booster Flow Rate Performance (SCFM) Flow and Pressure Performance: Sample performance shown below is used for general reference only; consult Haskel Technical Sales or your Haskel Representative for specific performance information. Cubic Meters Per Minute = SCFM x 0.0283 Catalog Number AG-4 AG-7 AG-15 AG-30 AG-50 AG-62 AG-75 AG-102 AG-152 AG-233 AG-303 AGD-1.5 AGD-4 AGD-7 AGD-14 AGD-15 AGD-30 AGD-32 AGD-50 LEGEND Pa = Air Drive Pressure Ps = Gas Supply Pressure Qa = Air Drive Quantity Po = Gas Outlet Pressure Q = Gas Outlet Flow Rate

Abrir o catálogo na página 8

Alternative Gas Booster and System Models Specialty Gas Booster Models Standard Model Number Oxygen Booster Model Number Hydrogen Booster Model Number Standard Model Number Oxygen Booster Model Number Inert Gas Booster System Models Hydrogen Booster Model Number Standard Model Number Standard System Model Number Oxygen System Model Number Standard Model Number Standard System Model Number Oxygen System Model Number

Abrir o catálogo na página 9

Inert Gas Booster Systems Haskel’s ability to incorporate and interface electronic controls into systems provides precise compression and control of gases. Standard system components are: 1. Booster with External Pilot Modification to enable use of external components to start/stop the booster. 2. Adjustable Air Pilot Switch (inlet) – used to stop the booster when supply pressure falls to adjusted set point. 3. Adjustable Remoteset Air Pilot Switch (outlet) – used to stop the booster when outlet pressure reaches adjusted set point. 10 4. Pressure Gauge indicates outlet boosted pressure. 5....

Abrir o catálogo na página 10

Mini Charging Booster Designed and Manufactured to achieve an affordable and effective gas transfer and charging unit. Standard configuration includes cylinder mounting bracket. ScubAmp Used by Dive Shops to boost medium pressure breathing air from storage air direct to dive tanks to reach maximum fill pressure rapidly. With the use of a ScubAmp, existing air compressor systems can stay within their 200-2500 psi normal operating range. TYPICAL FILL TIMES AIR DRIVE INLET PORT 1/2’’ FNPT (150 PSIG MAX) To Nominal Tank Size and Pressure From Pressure in Storage (After Equalizing in Dive Tank)...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos Haskel

-

Hydrogen Compressors and Valves

7 Páginas

-

Subsea Valves

18 Páginas

-

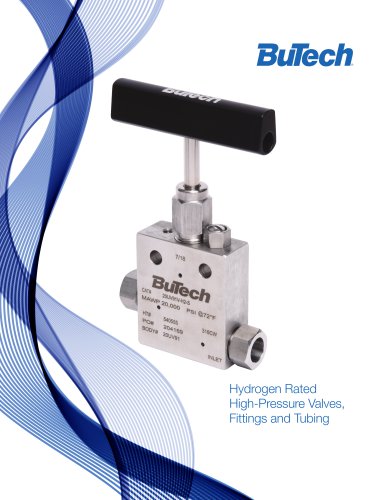

Hydrogen Valves

8 Páginas

-

Military and Defense Applications

7 Páginas

-

Electric Gas Compressor, Q-Drive

7 Páginas

-

Pneumatic Liquid Pump

28 Páginas

-

Refrigerant Pumps

2 Páginas

-

Freon, CFC & HCFCTransfer Units

1 Páginas

-

Butech Delivering Peak Performance

32 Páginas

-

Butech Oil Gas

12 Páginas

-

Air Pressure Amplifiers

12 Páginas

-

Pneumatic Driven Liquid Pumps_2019

28 Páginas

-

2019 Haskel Product Overview

4 Páginas

-

H-Drive Cut Sheets

2 Páginas

-

Mini Charging Cart

2 Páginas

-

Fire Fighting Safety

12 Páginas

-

HGD-90

2 Páginas

-

HGD-150

2 Páginas

-

HGT-90/63

2 Páginas

-

HGT-150/63

2 Páginas

-

HGT-150/90

2 Páginas

-

Bootstrap Nitrogen Boosters

2 Páginas

-

ScubAmp

2 Páginas

-

Oxygen Boosters

2 Páginas

-

Oil and Gas

6 Páginas

-

High Pressure Valves & System Components

16 Páginas

-

Air Pressure Amplifers

12 Páginas

-

H-Drive

4 Páginas

-

Oil & Gas

6 Páginas

-

Air Pressure Amplifier

12 Páginas

-

Liquid Pumps

28 Páginas

-

1.5 hp (1.12 kW) Pump Models

1 Páginas

-

Haskel Air Amplifier Literature

12 Páginas

-

Air and Hydraulic Driven Gas Boosters

36 Páginas

-

BuTech Subsea Valves

32 Páginas

Catálogos arquivados

-

Airline Industry

4 Páginas

-

2015 Haskel Product Overview

4 Páginas

-

PNEUMATIC DRIVEN LIQUID PUMPS_2009

28 Páginas

-

Tube Expansion Issues and Methods

4 Páginas

-

Breathing Air Compressor

2 Páginas