Excertos do catálogo

WELDING AND CUTTING AUTOMATION PLATE EDGE BEVELLING MACHINE - KBM-18® KBM-18® Plate Edge Bevellers - Portable - Self Propelled These plate bevellers produce clean machined bevels with no thermal distortion on mild steel, stainless steel and aluminum plate from 1/4” (6.0 mm) to 1 1/2” (38.1 mm) thick. Thinner material can be bevelled. Please consult the factory for details. The KBM-18® automatically bevels the topside of the plate which results in a reduction of time and cost. Savings are further enhanced when the KBM-18U® underside plate beveller is used in applications where both sides of the material require bevelling. Adjustable undercarriage for easy height adjustment. The KBM-18® can be purchased with an adjustable height, self-aligning, spring-loaded caster wheel assembly for self- propelled bevelling along any length of plate maintaining a uniform bevel and consistent root face. Undercarriage sold separate. Angle Bevel Pins Enable Bevel Angle Adjustment ... KBM-18® units are supplied with angle bevel pin for 30°. 22 1/2°, 37 1/2°, 45° and 55° bevels angle pins sold seperately. Pins for other bevel angles are available upon request. Operates at 10 feet (3 meters) per minute WITH ADJUSTABLE BEVELLING HEAD TO PRODUCE BEVEL ANGLES 22 1/2° THROUGH 55

Abrir o catálogo na página 1

HYDRAULIC ADJUSTABLE UNDERCARRIAGE For easy height adjustment KBM-18® units can be supplied with two types of undercarriage. Both are supplied with Gullco exclusive self-aligning caster wheel assemblies to maintaining a uniform bevel and consistent root face. Undercarriage sold separate Maximum Bevel Width: Maximum Bevel Depth: Min. Plate Thickness: Max. Plate Thickness: Bevel Speed: Motor: Weight: Complies With: 0.71” (18.00 mm) at standard 30° bevel angle on material with a tensile strength of 64,000 lb/ in 2 (45 Kg/mm2) 0.61” (15.6 mm) at standard 30° bevel angle on material with a...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos Gullco International Limited

-

ARCAIR-MATIC N7500 GOUGING SYSTEM

2 Páginas

-

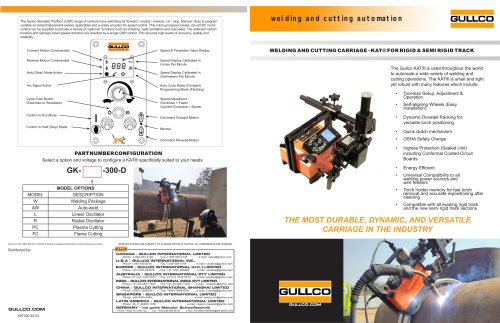

KAT® 300 SERIES

2 Páginas

-

ARC LENGTH SYSTEM | PLASMA AND TIG

2 Páginas

-

KAT®100 SERIES AUTOMATION CARRIAGE

2 Páginas

-

Self-centering welding gripper

2 Páginas

-

trackless welding carriage - moggy®

4 Páginas

-

KATBAK® Ceramic Weld Backing

3 Páginas

-

GK-200

2 Páginas

-

Welding Electrode Stabilizing Ovens

2 Páginas

-

GOV 100 FH - 100

2 Páginas

-

Pipe KAT- Rigid Band

4 Páginas

-

Pipe KAT - Operation

56 Páginas

-

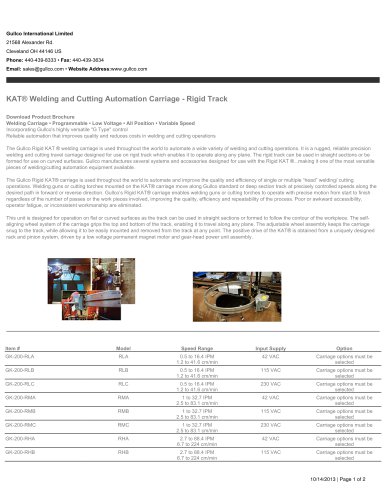

KAT® Rigid Track Carriage

4 Páginas

-

welding electrode drying ovens

4 Páginas

-

weld flux hoppers and rebake ovens

2 Páginas

-

GK-192

1 Páginas

-

rigid kat

1 Páginas

-

Customized Welding Gantry

4 Páginas

-

Vacuum Track Mounting System

4 Páginas

-

Welding Positioner

4 Páginas

-

Cutting Carriage - KAT II

2 Páginas

-

Orbital Welding System - Pipe KAT

4 Páginas

-

Welding Ovens - Electrode Drying

4 Páginas

-

Ceramic Weld Backing - KATBAK

4 Páginas

-

Auto-Weld Carriage System

2 Páginas

-

Automatic Overlay Welder

2 Páginas