Excertos do catálogo

Goulds Model 3996 In-Line Process Pumps Goulds Pumps

Abrir o catálogo na página 1

Goulds Model 3996 In-Line Process Pumps Designed for Total Range of Industry Services s Capacities to 1400 GPM (318 m3/h) s Heads to 700 feet (213 m) s Temperatures to 500° F (260° C) s Pressures to 375 PSIG (2586 kPa) Performance Features for In-Line Services Extended Pump Life • Integral pump bearings • TaperBore™ Plus/BigBore™ seal chambers • Precision fits for accurate alignment • Flexibly coupled Ease of Maintenance • In-line mounting • Field alignment not required • Back pull-out design • External impeller adjustment Safety • ANSI B15.1 coupling guard • Ductile iron frame and motor...

Abrir o catálogo na página 2

Model 3996 In-Line Process Pumps Heavy Duty Design Features for a Wide Range of Process Services STANDARD NEMA C-FACE NORMAL THRUST MOTOR FIELD ALIGNMENT NOT REQUIRED HIGH STRENGTH DUCTILE IRON MOTOR SUPPORT Precision rabbet locks provide positive, built-in alignment between pump and motor. Open on two sides for easy access to back pull-out assembly. FLEXIBLY COUPLED Conventional flexible spacer coupling. INTEGRAL PUMP BEARINGS All hydraulic loads carried by pump—not by motor. Bearings sized for 2-year minimum and 10-year average life under tough operating conditions. Regreaseable bearings...

Abrir o catálogo na página 3

In-Line Design For Cost Savings Setting The Standards For Reliability In-line pumps have become increasingly popular with users due to minimal floor space required and reduced installation costs. Installation is simple since the unit is mounted directly in the line like a valve. Field alignment is not required and the unit is not subject to misalignment due to pipe strain or temperature changes. The 3996 is designed for optimum reliable service ...shaft size and overhang are optimized to provide maximum seal and bearing life...precision fits provide built-in alignment between pump and motor...

Abrir o catálogo na página 4

Parts List and Materials of Construction Material Item Number Part Name Ductile Iron Ductile Iron Ductile Iron Lantern Ring Thrust Bearing Shaft—Less Sleeve (Optional) Shaft—With Sleeve Shaft Sleeve Bearing Locknut and Lockwasher Radial Bearing Stuffing Box Cover (Packed Box) Ductile Iron Seal Chamber (Mechanical Seal) Ductile Iron Bearing Frame Motor Support Repeller/Sleeve (Dynamic Seal Option) Gasket, Cover to Backplate (Dynamic Seal) Stud/Nut, Cover to Frame Grease Seal (Outboard) Glass-Filled Teflon* Teflon* Impregnated Fibers Double Row Angular Contact Steel SAE4140 Teflon* 304SS Buna...

Abrir o catálogo na página 5

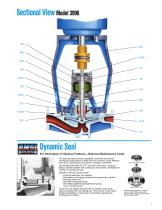

Sectional View Model 3996 Dynamic Seal For Elimination of Sealing Problems—Reduced Maintenance Costs On tough pumping services, especially corrosives and slurries, mechanical seals require outside flush and constant, costly attention. Even then, seal failures are common, resulting in downtime. Goulds offers the ANSI PLUSTM Dynamic Seal which, simply by fitting a repeller between the stuffing box and impeller, eliminates the need for a mechanical seal. Benefits of Goulds Dynamic Seal: • External seal water not required • Elimination of pumpage contamination and product dilution • Reduces...

Abrir o catálogo na página 6

Hydraulic Coverage Model 3996 m 240

Abrir o catálogo na página 7

Sealing Solutions Goulds engineered seal chambers are designed to accept a wide range of sealing arrangements to meet specific user requirements. Your Goulds representative will gladly recommend the best sealing solution for your service...some of which are illustrated here. SINGLE CARTRIDGE SEAL (with TaperBoreTM PLUS Seal Chamber) • Same application as conventional single seal • Ease of maintenance • No seal setting problems CONVENTIONAL DOUBLE SEAL (with BigBoreTM Seal Chamber) • Liquids not compatible with single seal • Toxic, hazardous, abrasive, corrosive • When pump is operating...

Abrir o catálogo na página 8

Dimensions Model 3996 All dimensions in inches and (mm). Not to be used for construction. MINIMUM HEADROOM REQUIRED TO REMOVE MOTOR – 6 IN. (152) DIMENSIONS Pump Weight (Less Motor) Lbs. (kg) Pump Size ANSI Designation X-Series Power Ends Fit 8 Different Process Pumps Minimize inventory, reduce downtime. Model 3196 X-Series Chemical Process Pumps Model CV 3196 Non-Clog Process Pumps Model HT 3196 High Temperature Chemical Process Pumps Model LF 3196 Low Flow ANSI Process Pumps Model NM 3196 FRP Process Pumps Model 3198 PFA TEFLON®-Lined Process Pumps Model 3796 Self-Priming Process Pumps...

Abrir o catálogo na página 9Todos os catálogos e folhetos técnicos Goulds Pumps

-

IC i-FRAME series

11 Páginas

-

3420 series

11 Páginas

-

3316 series

12 Páginas

-

JC series

12 Páginas

-

3175 series

16 Páginas

-

3196 i-FRAME series

24 Páginas

-

AF series

8 Páginas

-

3180

20 Páginas

-

3700

12 Páginas

-

Goulds 7200SB

12 Páginas

-

Vertical Turbine Pumps

20 Páginas

-

Goulds 3400

11 Páginas

-

Goulds AF

8 Páginas

-

IC i-FRAME

24 Páginas

-

Goulds API 3600 i-FRAME®

12 Páginas

-

Goulds ICP

8 Páginas

-

Goulds ICO i-FRAME® Series

16 Páginas

-

Goulds API 3620 i-FRAME®

16 Páginas

-

Goulds 3175

16 Páginas

-

Goulds API 3171

8 Páginas

-

Goulds 3171 / CV 3171

16 Páginas

-

Goulds Pumps History Brochure

4 Páginas

-

Goulds 3355

7 Páginas

-

Goulds 3335

4 Páginas

-

Goulds 3316

12 Páginas

-

Goulds 3298

20 Páginas

-

Goulds 3180

20 Páginas

-

Goulds JC Slurry Pump

10 Páginas

-

Goulds 5500 Severe Duty Slurry Pumps

11 Páginas

-

Goulds JCU

8 Páginas

-

Goulds HS / HSD

4 Páginas

-

Goulds V 3298 Chemical Process Pumps

20 Páginas

-

Goulds NM 3196 i-FRAME FRP Process Pumps

11 Páginas

-

Goulds ICB Close-Coupled

19 Páginas

-

Goulds IC ISO Chemical Process Pumps

20 Páginas

-

Goulds 3196 i-FRAME Process Pump

19 Páginas

-

7200CB Barrel Multistage Pumps

12 Páginas

-

Goulds 3640

8 Páginas

-

Pump Selection Guide

16 Páginas

-

Goulds Model JC Slurry Pump

10 Páginas

-

Vertical Cantilever Pump VHS

9 Páginas

-

XHD Extra Heavy Duty Lined Slurry Pumps

11 Páginas

-

SealPlus Mechanical Seals

4 Páginas

-

ICM

8 Páginas

-

Products for the Oil and Gas Industry

12 Páginas

-

Goulds NM3196 i-FRAME FRP Process Pumps

11 Páginas

-

Pumps for the Sugar Processing Industry

12 Páginas

-

Mining & Mineral Processing

12 Páginas

-

Solutions for the Biofuels Industry

8 Páginas

-

Products for Pulp and Paper

4 Páginas

-

Pumps for Power Generation

8 Páginas

-

Wet Pit Column Pumps

4 Páginas

-

Single Suction Dry Pit Pumps

2 Páginas

-

Model HS and HSD

4 Páginas

-

LF 3196 i-FRAME

11 Páginas

-

CV 3196 i-FRAME

11 Páginas

-

Goulds 3296 EZMAG Chemical Process Pump

11 Páginas

-

Goulds 3198 i-FRAME

11 Páginas

-

Goulds 3185 Heavy-duty Process Pumps

20 Páginas

-

Goulds Trash Hog®

11 Páginas

-

Goulds 3180 Heavy-duty Process Pumps

20 Páginas

-

Goulds 3796

11 Páginas

-

HT 3196 i-FRAME

14 Páginas

-

Goulds 3298 Chemical Process Pumps

20 Páginas

-

Goulds 3400 Double Suction Pumps

11 Páginas

-

Goulds API 3171

4 Páginas

-

3196 i-FRAME

19 Páginas

Catálogos arquivados

-

Goulds 3420 Double Suction Pumps

11 Páginas

-

3180 i-ALERT Paper Stock/Process Pumps

20 Páginas

-

Multi-Stage Diffuser Type Pump 3935

7 Páginas

-

Goulds Model 3900

13 Páginas

-

Medium Consistency Pump Systems

11 Páginas

-

Goulds 3355 Multistage Process Pumps

7 Páginas

-

Multi-stage diffuser type pump 3335

4 Páginas

-

Goulds Model 3175

15 Páginas

-

Goulds 3910

11 Páginas

-

Goulds Model 5500

11 Páginas

-

Goulds AF Axial Flow Pumps

11 Páginas

-

Goulds Molten Sulfur Pumps

2 Páginas