Website:

FPT Industrial S.p.A.

Website:

FPT Industrial S.p.A.

Grupo: Iveco Group

Excertos do catálogo

AFTERTREATMENT SYSTEMS FOR MEDIUM AND HEAVY ENGINES SCR SYSTEM DIESEL PARTICULATE FILTER GENUINE PARTS

Abrir o catálogo na página 1

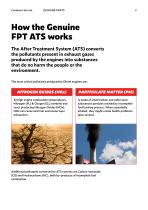

Customer Service GENUINE PARTS How the Genuine FPT ATS works The After Treatment System (ATS) converts the pollutants present in exhaust gases produced by the engines into substances that do no harm the people or the environment. The most critical pollutants produced by Diesel engines are: NITROGEN OXIDES (NOx) At high engine combustion temperatures, Nitrogen (N2) & Oxygen (O2) combine and react producing Nitrogen Oxides (NOx). NOx can cause acid rain and ozone layer exhaustion. PARTICULATE MATTER (PM) Is made of small carbon and other toxic substances particles created by incomplete fuel...

Abrir o catálogo na página 2

Customer Service GENUINE PARTS FPT has selected the combination of SCR (Selective Catalytic Reduction) and DPF (Diesel Particulate Filter) for the medium (NEF) and heavy engine (Cursor) families to meet Euro VI emission standards and following. SCR (Selective Catalytic Reduction) system has the task to reduce di NOx emissions by using gaseous ammonia (NH3). Ammonia is created by the conversion of DEF (Diesel Exhaust Fluid) injected in the exhaust line. DPF (Diesel Particulate Filter) has the task to physically trap the solid soot particles produced by the diesel engine combustion. UREA...

Abrir o catálogo na página 3

Customer Service GENUINE PARTS SCR N2 NO2 NO AdBlue Urea + Water dosing system Control system connected to engine CPU The injector introduces the DEF (stored into a specific tank) in front of the mixer element. DEF standard composition is made of 32,5% urea and 67,5 demineralized water and this solution is sold in Europe under the trade name of AdBlue®. The mixer element will combine the AdBlue with the exhaust gases into a homogeneous gaseous mixture. The mixture enters the SCR catalyst where the chemical reactions take place. The SCR transforms NOx into water vapor and Nitrogen, common...

Abrir o catálogo na página 4

Customer Service GENUINE PARTS DOC & DPF Diesel Oxidation Catalyst (DOC) is a device capable to promote a series of oxidation reactions using O2 in lean operative conditions. Diesel particulate filter (DPF) has the function to retain and accumulate particles coming from exhaust gases and prevent them of being released into the atmosphere. Its structure is made by alternatively open/closed porous ceramic channels, so that, because of their size, particles are trapped inside the filter while gases pass through the porous walls. When there are enough soot particles accumulated into the...

Abrir o catálogo na página 5

Customer Service GENUINE PARTS Genuine FPT ATS performance Inside the combustion chamber, Particulate Matter (PM) and Nitrogen Oxides (NOx) have conflicting chemical factors. A high combustion temperature leads to economic fuel consumption and low particulate (PM) levels, BUT it generates a high rate of NOx production. When the engine is operating most efficiently for power, minimal PM is produced. However, the NOx levels are very high. When exhaust gas is recirculated back into the intake, the NOx production is reduced. However, higher levels of PM are created. NO DIESEL ENGINE currently...

Abrir o catálogo na página 6

Customer Service GENUINE PARTS Why you should choose a Genuine FPT ATS As the emission legislation becomes more and more severe, it is fundamental that the engine is developed together with its ATS system: each phase in the combustion chamber, in any working condition, must be finely calibrated to ensure the best possible ambience for catalyzation and filtration processes to always meet the emission requirements and performance targets. FPT develops specific solutions, according to the characteristics and the mission profile each FPT engine has been designed for. Every component of the ATS...

Abrir o catálogo na página 7

24/7 CARE & ASSISTANCE Please, don’t hesitate to contact us for any further information fptindustrial.com

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos FPT Industrial S.p.A.

-

C90 410

6 Páginas

-

N67 NG-CONSTRUCTION

1 Páginas

-

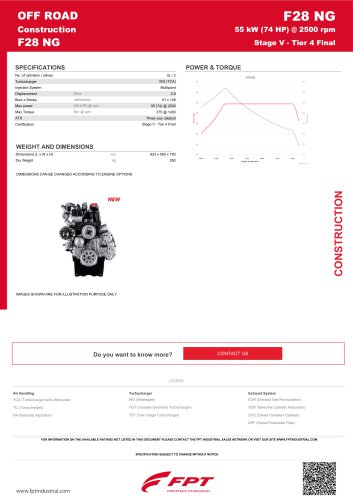

F28 NG-CONSTRUCTION

1 Páginas

-

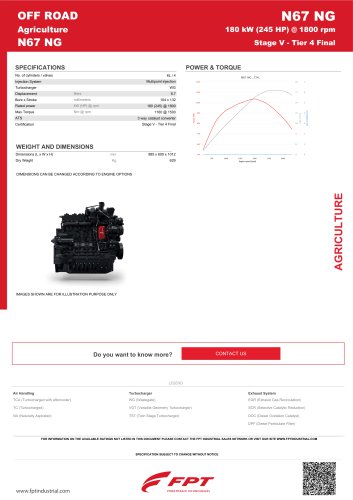

N67 NG-AGRICULTURE

1 Páginas

-

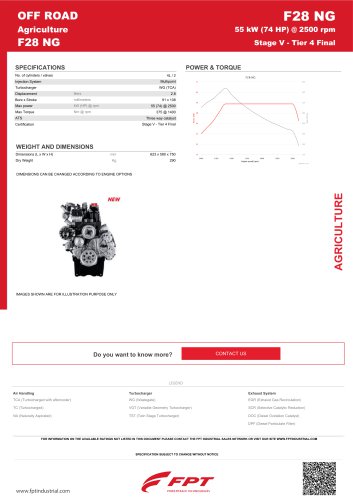

F28 NG

1 Páginas

-

CURSOR 9 NG-BUSES

1 Páginas

-

XCURSOR 13 NG

1 Páginas

-

XCursor 13

1 Páginas

-

N67 NG-BUSES

1 Páginas

-

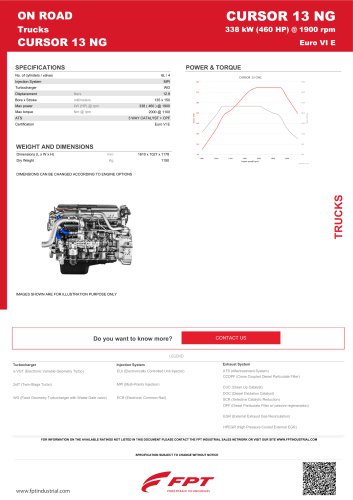

CURSOR 13 NG

1 Páginas

-

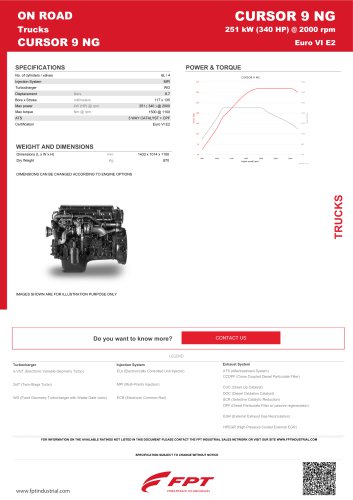

CURSOR 9 NG

1 Páginas

-

N67 NG

1 Páginas

-

WATER PUMP

6 Páginas

-

TURBOCHARGER

6 Páginas

-

STARTER MOTOR

6 Páginas

-

SHORT BLOCK

6 Páginas

-

OIL FILTER

8 Páginas

-

LONG BLOCK

6 Páginas

-

INJECTOR

8 Páginas

-

HIGH PRESSURE PUMP

8 Páginas

-

FPT GENUINE CYLINDER HEAD

6 Páginas

-

FUEL FILTER

8 Páginas

-

ALTERNATOR

10 Páginas

-

Bullettin FPT Industrial Fluids – EMEA

11 Páginas

-

Bullettin FPT Industrial Fluids – KOREA

13 Páginas

-

Bullettin FPT Industrial Fluids – CINA

22 Páginas

-

Brochure MyFPT App

6 Páginas

-

Brochure REMOTE ASSISTANCE

13 Páginas

-

PROACTIVE ASSISTANCE

7 Páginas

-

F1A 85 kW

1 Páginas

-

N45

1 Páginas

-

F1C NG

1 Páginas

-

FPT INDUSTRIAL MARINE COMMERCIAL

27 Páginas

-

S8000

1 Páginas

-

GENERATOR SETS

20 Páginas

-

ON ROAD

51 Páginas

-

OFF ROAD CONSTRUCTION

33 Páginas

-

MARINE

26 Páginas

Catálogos arquivados

-

OFF ROAD AGRICULTURE 2022

37 Páginas

-

OFF ROAD AGRICULTURE 2019

33 Páginas

-

ON ROAD_2016

60 Páginas

-

POWER GENERATION

70 Páginas

-

MARINE

40 Páginas

-

OFF ROAD

74 Páginas