Website:

FAFNIR GmbH

Website:

FAFNIR GmbH

Grupo: Gilbarco Veeder-Root

Excertos do catálogo

The Automatic Monitoring System for Active Vapour Recovery Sensors & Systems Worldwide: www.fafnir.com

Abrir o catálogo na página 1

FAFNIR GmbH: Innovation with Tradition. Quality and Satisfaction – made in Germany Company The FAFNIR GmbH, based in Hamburg, Germany, develops and manufactures since 1965 filling s afety devices, overfill prevention devices, limit signal controllers and continuous level gauging solutions for all types of liquid. The optimisation of process controls, improvements in cost efficiency and the protection of p eople and the environment are at the heart of our business. Our close and trusting relationship with our customers is a key factor in the practice-oriented implementation of innovative...

Abrir o catálogo na página 2

The Automatic Monitoring System for active Vapour Recovery FAFNIR As an automatic monitoring system for the active vapour recovery VAPORIX serves as protection for people and environment. Product information The VAPORIX automatic monitoring system provides information about the functional state of the active vapour recovery and thus complies with the legal requirements. Application The VAPORIX automatic monitoring system is especially designed for use in petrol stations. Due to its modular structure VAPORIX can be used in all known active vapour recovery systems and fuel dispensers. ■...

Abrir o catálogo na página 3

Function The flow sensor VAPORIX-Flow is based on the calorimetric measuring principle. The medium which flows past a heated sensor element absorbs the energy and thus cools it. The volume flow can be concluded from the absorbed heat energy. The incoming media parameters (HC and air) are adjusted by the simultaneous coverage of the HC concentration, i.e. the measured volume flow is captured independently of the media. System design Installation instructions VAPORIX-Flow is installed in the vapour recovery pipe before the pump and before any existing control valve and/or...

Abrir o catálogo na página 4

Technical data Sensor VAPORIX-Flow Connections »» Connection to the VAPORIX-Control »» Connecting thread: G ⅜“ Operating data »» Explosion protection: II 1 G Ex ia IIB T3 Ga »» Approvals: TÜV 99 ATEX 1509, IECEx TUN 08.0008 »» Index of protection IP68 »» Perm. ambient temp.: - 40 °C to + 65 °C Dimensions »» Installation length: 269 mm Edition 05.16 Technical changes reserved

Abrir o catálogo na página 5

Technical data Control unit VAPORIX-Control Connections »» Power supply: 230 V ~ … »» Pulse inputs: rectangular signal with 5…24 V pulse height, max. 1 kHz, duty factor 20…80 % »» Pulse valency: 100 pulses / litre default setting; Optional: 33 / 50 / 132 / 200 pulses / litre default setting »» Outputs: 2 x galvanically isolated transistor outputs max. 30 V, 100 mA 6 | VAPORIX-Control – Technical data »» Interfaces: 1 x RS-232 (service), 1 x RS-485 4-wire (dispenser computer), 1 x RS-485 2-wire (SECON, DOMS, POS) Edition 05.16 Technical changes reserved Operating data »» Explosion...

Abrir o catálogo na página 6

Edition 05.16 Technical changes reserved FAFNIR VAPORIX - Order code VAPORIX Control - Order Code 7

Abrir o catálogo na página 7

Condensate Separator The Condensate Separator for Vapour Recovery Systems Features of the FAFNIR technology Product information The condensate separator is designed for fuel dispensers to be retrofitted with decentralized active vapour recovery systems. The condensate separator collects large quantities of condensate and converts it back into a gaseous state. It is designed for the requirements of vapour recovery systems at petrol stations. ■ Ideal for retrofitting existing equipment ■ Robust construction ■ Maintenance-free The application of the condensate separator increases the lifetime...

Abrir o catálogo na página 8

Condensate separator Edition 05.16 Technical changes reserved FAFNIR Installation instructions The condensate separator is integrated into the vapour recovery system between the nozzle and the vapour recovery pump. In order to guarantee a proper operation the following installation instructions should be observed: » The installation position of the condensate separator must always be vertical, i. e. in an upright position (see the drawing). » The supply connections must not be interchanged. » To fasten the condensate separator standard pipe clamps can be used, if necessary. » After...

Abrir o catálogo na página 9

The pulse correction module for vapour recovery systems VAPORIX PCM (Pulse Correction Module) extends and improves the function of pulsecontrolled vapour recovery systems. Function With the help of its micro-controlled electronics VAPORIXPCM reverts to the established history data base inside the VAPORIX-Control. This historybased knowledge enables a highly effective corrective control of the vapour recovery. All influences that could affect the vapour recovery are included. The result is an excellent corrective control that exactly diagnoses failures of the vapour recovery. Features of...

Abrir o catálogo na página 10

Process flow Corrected control pulses Side A VAPORIX-PMC - Technical data 11

Abrir o catálogo na página 11

FAFNIR GmbH Schnackenburgallee 149 c 22525 Hamburg, Germany Phone: Fax: E-Mail: info@fafnir.com Internet: www.fafnir.com Sensors & Systems Worldwide: www.fafnir.com

Abrir o catálogo na página 12Todos os catálogos e folhetos técnicos FAFNIR GmbH

-

TORRIX M12 MOBILE

2 Páginas

-

TORRIX XTS

2 Páginas

-

TORRIX 6

1 Páginas

-

LPG Sensors

8 Páginas

-

SEPARIX

8 Páginas

-

Process Automation

28 Páginas

-

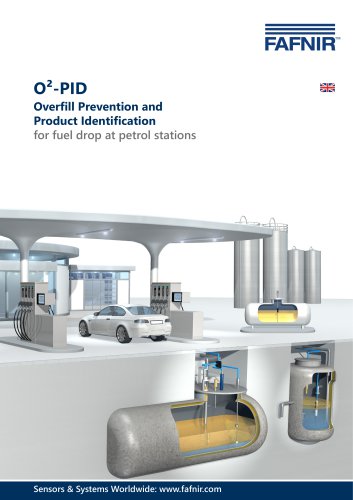

O²-PID

4 Páginas

-

COMS Leaflet

4 Páginas

-

VAPORIX Flow and Control

40 Páginas

-

Wallmounting Typ 907

4 Páginas

-

QE 200

4 Páginas

-

UM 2.1/2.2/2.3

20 Páginas

-

TORRIX HART

28 Páginas

-

TORRIX RS485 Modbus

16 Páginas

-

TORRIX M12

40 Páginas

-

FAFNIR Universal Device Protocol (UDP)

30 Páginas

-

FAFNIR Hart Setup

9 Páginas

-

LS 300 / 500

7 Páginas

-

76 A / NB 220

5 Páginas

-

76 / NB 220

2 Páginas

-

SECON-X

4 Páginas

-

PRESSURIX

12 Páginas

-

Insite360

4 Páginas

-

Plugs

12 Páginas

-

UM 2.1/UM 2.2/UM 2.3

20 Páginas

-

TORRIX-HART

28 Páginas

-

DIVELIX

8 Páginas

-

CONDURIX-HART

28 Páginas

-

CONDURIX

24 Páginas

-

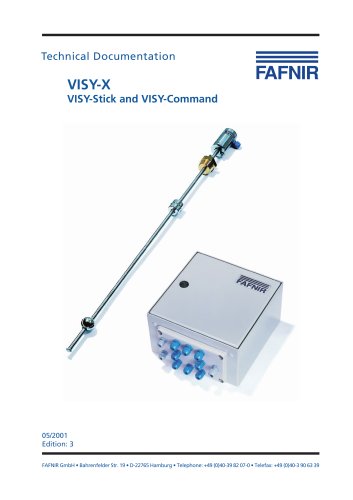

VISY-X

24 Páginas

-

Accessories

3 Páginas

-

VISY-Command Web

4 Páginas

-

VISY-Reed

4 Páginas

-

VISY-RF

2 Páginas

-

VISY-Stick

15 Páginas

-

VISY-TD Display

2 Páginas

-

VISY-View Touch

2 Páginas

-

VPI - VISY-Power Interface

1 Páginas

-

TORRIX

10 Páginas

-

TORRIX CI

1 Páginas

-

TORRIX RS485

3 Páginas

-

UM-X Transducer

3 Páginas

-

TEMPERIX

8 Páginas

-

Overfill Prevention & Accessories

12 Páginas

-

VISY-Input VISY-Output

4 Páginas

-

VISY-Command

5 Páginas

-

LPG-Sensoren

8 Páginas

Catálogos arquivados

-

2019 VISY-Stick Flex

2 Páginas

-

2016 VISY-Stick Flex

2 Páginas

-

HPH Ex d

3 Páginas

-

VISY-Monitor

2 Páginas

-

VISY-X LON

10 Páginas

-

SEPARIX

23 Páginas

-

VAPORIX Flow/Control

32 Páginas

-

VISY-Setup V 3.1.0

40 Páginas

-

VISY-Setup V2.10

42 Páginas

-

VISY-View

24 Páginas

-

VISY-Stick and VISY-Command

24 Páginas

-

Overfill Prevention (GWG)

12 Páginas