Website:

Cubic Sensor and Instrument Co.,Ltd

Website:

Cubic Sensor and Instrument Co.,Ltd

Grupo: Cubic

Excertos do catálogo

Product Name: Single Beam NDIR CO2 Sensor Module Item No.: CM1106-C(0-5000ppm version) Version: V0.2 Date: 19th September,2019

Abrir o catálogo na página 1

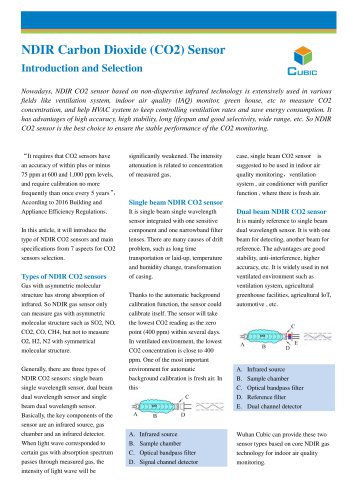

Single Beam NDIR CO2 Sensor Module CM1106-C(0-5000ppm version) Applications ▪ HVAC industry ▪ IAQ monitor ▪ Air purifier ▪ Automotive ▪ IoT devices ▪ Plant growth Description CM1106-C(0-5000ppm version) is a single beam NDIR CO2 sensor module, based on non-dispersive infrared (NDIR) technology, which can detect CO2 concentration of indoor air. With high accuracy, high stability, small size, it is widely used for ventilation system, air purifier, air conditioner, HVAC transmitter, IAQ monitor, etc. ▪ NDIR technology with independent intellectual property ▪ High accuracy, long term stability,...

Abrir o catálogo na página 3

Typical Application Circuit Application scene: UART TTL serial port output Description of Calibration Auto Calibration: Rough installing, non-correct soldering and transportation might result in a reducing of sensor reading accuracy and zero drift, sensor will correct the drift by the built-in self-correcting logic. Powering on the sensor for 15 days continuously, it will record the lowest CO2 concentration measurement value during these 15 days. Sensor will do auto calibration after 15 days and will regard the outdoor fresh air CO2 concentration (400ppm) as baseline. In order to ensure the...

Abrir o catálogo na página 6

PWM cycle: 1004ms Positive pulse width: 0-5000: (PPM/5) + 2ms CO2 concentration detection value: 500ppm range: (PWM Positive pulse width -2) *5 PWM output schema: Alarm Output If the CO2 concentration rises up to more than 1000ppm, the alarming will be triggered and output high level. When the CO2 concentration goes down to below 800ppm, the alarming will stop and output low level. Note Connect the pin of PWM to the oscilloscope. Add a pull-up resistor around 5K-10K between the pin of PWM and power supply.

Abrir o catálogo na página 7

Product Installation 1. In order to ensure airflow diffusion into the sensor inner, make sure the minimum distance between the area of waterproof filter and the other components is 1.5 mm, otherwise, quick response time of the sensor will be effected. Reference as below: 2. To avoid the influence of stress on sensor, please soldering by hand as much as possible when mounting the sensor to the PCB. Reference as below:

Abrir o catálogo na página 8

UART Communication Protocol 1. General Statement 1).The data in this protocol is all hexadecimal data. Example: “46” for decimal [70]. 2). Baud rate: 9600, Data Bits: 8, Stop Bits: 1, Parity: No, Flow control: No. 3). [x x] is for single-byte data (unsigned, 0-255); for double data, high byte is in front of low byte. 2. Format of Serial Communication Protocol Sending format of test software: Start Symbol Detail description on protocol format: Protocol Format Start Symbol Sending by test software is fixed as [11H], module response is fixed as [16H] Length of frame bytes= data length +1...

Abrir o catálogo na página 9

Note: CO2 measured result = DF1*256+DF2 DF3 DF4 is reserved Example: Response: 16 05 01 02 58 00 00 8B Explanation: Hex is converted to decimal: 02 is 02; 58 is 88 CO2 concentration =02*256+88 = 600ppm 4.2 Calibration of CO2 Concentration Send: 11 03 03 DF1 DF2 CS Response: 16 01 03 E6 Function: Calibration of CO2 concentration Note: 1. Calibration target value = DF1*256+DF2 Unit: PPM, range (400-1500ppm) 2. Before calibration, please make sure CO2 concentration in current ambient is calibration target value. Keeping this CO2 concentration for two 2 minutes, then began calibration. Example:...

Abrir o catálogo na página 10

Response: 16 01 10 D9 Explanation: DF1: reserved, default 100 (0x64) DF2: open/close auto calibration (0: open; 2: close) DF3: calibration cycle (1-30 days optional, default is 15days) DF4: High base value (2 bytes) DF5: Low base value (2 bytes) DF6: reserved, default is 100 (0x64) Note: The auto calibration function is open with 15 days calibration cycle by default. The default value of DF4 and DF5 is 400, that is DF4: 01; DF5:90 4.4.1 Open ABC and Set Calibration Cycle Send: 11 07 10 64 00 07 01 90 64 78 Response: 16 01 10 D9 4.4.2 Close ABC Send: 11 07 10 64 02 07 01 90 64 76 Response:...

Abrir o catálogo na página 11

tSU.DAT (setup time of the data ) tSU.STO (setup time of the stop bit) Note: SCL clock frequency is generated by the master device with the range 10khz~400khz. Picture1: I2C clock introduction 1.3 Basic Data Transmission Formats S Picture 2: The general data format sends from the master device to the slave S Picture 3: The general data format received from the slave device to the master device The meaning of the symbol in picture 1.2 and picture 1.3: S: start condition SA: slave address W: write bit R: read bit A: acknowledge bit ~A: not acknowledge bit D: data, each data is 8bit P: stop...

Abrir o catálogo na página 12

Picture 4: The address byte sent from the master device 1.5 Notes The performance of the MCU which is used in the sensor is not very high. If you use I/O port to simulate I2C master device, it is suggested to reserve a period before and after ACK signal (such as 100 us), after sending every byte (8 bit) to leave enough time for the SCM to process the data. Within requirements of speed, it is recommended to lower the reading speed as much as possible. 2.1 Statement of Measuring Command The slave address is 0x31, the data command of the slave device is as below:

Abrir o catálogo na página 13

2.2 Measuring Result The master device should send command of measuring result. Send:0x01 Response: [0x01][DF0][DF1][DF2][CS] Note: 1. Sensor starts measuring result status once receiving the command 0x01. After this, all the data which I2C read will be such status format data, until the sensor receives new command or re-powering on. 2. Data format, master device receives DFq first, and then receives CS at last.

Abrir o catálogo na página 14

2.4 Calibration The master device should send command of calibration. Send: 0x03 [DF0] [DF1] Response: [0x03] [DF0] [DF1] [CS] Note: 1. Sensor starts calibration status once receiving command 0x03. After this, all the data which I2C read will be such status format data, until the sensor receives new command or re-powering on. 2. Data format, master device receives DF0 first, and then receives CS at last. The result is calculated by high bit in front: [DF0] * 256 + [DF1]. 3. Five integers form a 20-bit code.

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos Cubic Sensor and Instrument Co.

-

Cubic Ultrasonic Gas Metering Solutions

10 Páginas

-

Cubic Smart Water Metering Solution

6 Páginas

-

Cubic Gas Sensor Solutions Overview

7 Páginas

-

Cubic Automotive Gas Sensor Solution

23 Páginas

-

Cubic TDLAS CH4 Sensor

4 Páginas

-

Cubic Environmental Air Quality Sensors

16 Páginas

-

Cubic-IoT Smart Gas Sensor Solutions

2 Páginas

-

Gasboard-7500H-OPC

13 Páginas

-

Electrochemical CO Sensor ECO-5011

2 Páginas

-

TDLAS CH4 Sensor Gasboard-2500

2 Páginas

-

Air quality monitor AM7000_2021

1 Páginas

-

NDIR CO2 Sensor Module-CM1106H-NS

11 Páginas

-

NDIR CO2 Sensor Module-CM1106LS

18 Páginas

-

Dual Beam NDIR CO2 Sensor-CM1107T

11 Páginas

-

Laser Particle Sensor-PM2008M-M

22 Páginas

-

Dual Beam NDIR CO2 Sensor-CM1107BN

13 Páginas

-

PM2015-M Laser Particle Sensor Module

21 Páginas

-

Integrated Air Quality Sensor-AM1008W

16 Páginas

-

PM1006K LED Particle Sensor Module

12 Páginas

-

PM2009 Laser Particle Sensor Module

20 Páginas

-

Laser Particle Sensor-PM2012

19 Páginas

-

Test Instruction of AM4100-I

7 Páginas

-

Test Instruction of AM1008W

7 Páginas

-

Test Instruction of PM5000

7 Páginas

-

Test Instruction of PM1006

8 Páginas

-

Test Instruction of CM1107T

7 Páginas

-

Test Instruction of CM1107BN

8 Páginas

-

Test Instruction of PM3006T

7 Páginas

-

Test Instruction of PM2009

8 Páginas

-

Test Instruction of PM2008M-M

8 Páginas

-

Test Instruction of CM1106SH

8 Páginas

-

Test Instruction of CM1107

8 Páginas

-

Test Instruction of CM1106SL-N

8 Páginas

-

Test Instruction of CM1106S

8 Páginas

-

Test Instruction of CM1106LS

8 Páginas

-

Integrated Air Quality Sensor-AM4100-I

12 Páginas

-

Laser Particle Sensor-PM2008

21 Páginas

-

Laser Particle Sensor-PM2009

20 Páginas

-

Laser Particle Sensor-PM2105-M

20 Páginas

-

NDIR CO2 Sensor Module-CM1106S

18 Páginas

-

Low Power CO2 Sensor Module-CM1106SL-N

16 Páginas

-

Dual Beam NDIR CO2 Sensor Module-CM1107N

19 Páginas

-

Laser Particle Sensor Module-PM2008SE

24 Páginas

-

Ultrasonic Oxygen Sensor Gasboard8500

10 Páginas

-

mainstream NDIR ETCO2 sensor module

1 Páginas

-

Ultrasonic Technology Introduction

1 Páginas

-

Total Solution for Syngas Analyzer

13 Páginas

-

Industrial NIDR CO2 Sensor SRH

1 Páginas

-

Gas Sensor Line-up

1 Páginas

-

About Cubic

1 Páginas

-

Online Flue Gas Analyzer Gasboard 3000UV

12 Páginas

-

Online Flue Gas Analyzer Gasboard 3000

12 Páginas

-

CEMS Solution - Gasboard 9050

22 Páginas

-

NDIR CO2 Sensor Modules

7 Páginas

-

Gasboard-7020

4 Páginas

-

Gasboard-7500

7 Páginas

-

Mainstream ETC02 module

5 Páginas

-

Gasboard 3400P

5 Páginas

-

Portable GAS3100P Syngas Analyser

5 Páginas

-

Analyzer Gasboard 3800P

6 Páginas

-

LANDFILL APPLICATIONS

8 Páginas

-

Ultrasonic Gas Flow and Oxygen Sensor

11 Páginas

-

Laser Particle Sensor Features

1 Páginas

-

INFRARED (NDIR) CO2 GAS SENSOR

8 Páginas

Catálogos arquivados

-

Air quality monitor AM7000

11 Páginas

-

What is Ultrasonic Oxygen Sensor

2 Páginas

-

INFRARED METHANE (CH4 ) GAS SENSOR

8 Páginas

-

RHB Series

8 Páginas

-

Electrochemical (ECD) FIXED H2S GAS

6 Páginas

-

INFRARED (NDIR) PORTABLE Hydrogen

8 Páginas

-

Online biogas analyzer Gasboard 3200

1 Páginas

-

Ultrasonic Flow meter 7200

1 Páginas

-

Syngas portable analyzers

4 Páginas

-

Opacity meter

1 Páginas

-

Automobile exhaust gas analyzer

3 Páginas

-

Ultrasonic flow meter BF-3000

1 Páginas

-

Ultrasonic gas flow meter BF-3000

4 Páginas

-

Infrared handheld CH4 gas detector

2 Páginas

-

Infrared Carbon Dioxide gas sensor

4 Páginas

-

Infrared Methane gas sensor

3 Páginas