Website:

Chr. Mayr GmbH + Co. KG

Website:

Chr. Mayr GmbH + Co. KG

Excertos do catálogo

your reliable partner

Abrir o catálogo na página 1

your reliable partner Characteristics and Advantages • High precision and reliability • Optimum running smoothness • High speeds • Robust and highly dynamic • Different designs for optimum set-up Design ROBA®-DS disk pack couplings of the type series 9110 and 9210 are especially adapted for the attachment of HBM torque transducers. Different types of construction and flexible combination possibilities permit the integration of measurement flanges in almost every test stand and drive constellation (see the Installation and Operational Instructions B.9110._ _). Function ROBA®-DS disk pack...

Abrir o catálogo na página 2

your reliable partner Contents Assignment of the torque transducers 1) In this torque range, the shaft coupling must be assigned according to the application. 2) See pages 12 - 13

Abrir o catálogo na página 3

O mayr your reliable partner Frictionally-locking transmittable torques Shrink disk hubs Frictionally-locking transmittable torques Tr [Nm] in relation to max. speed Type 9110._ Suitable for H6 / h6 at max. speed Type 9210._ transmittable torque reduces by approx. 30 % Suitable for H5 / h5 other tolerances, e.g. for motor shaft tolerance ‘k’ or ‘m’, possible on request 300 500 850 Attention! . -Please observe the permitted coupling torques of the coupling size used. Shrink disk hub “Standard” External clamping Internal clamping Shrink disk hub “High-Speed”

Abrir o catálogo na página 4

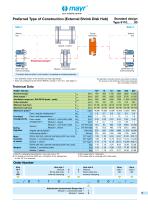

your reliable partner Preferred Type of Construction (External Shrink Disk Hub) Standard design Type 9110._ _ _00 Torque transducer Preferred variant * Shrink disk hub, external clamping Shrink disk hub, external clamping Module 1, connection plate ** The shrink disk hub (side 1) with module 1 is supplied as a finished assembly. * The “preferred variant” is the shortest and most rigid design. ** Does not correspond to the former HBM ID. number 1-4411.011_ (see page 11) The depicted connection screws are included in delivery. The screws for the left flange of the torque transducer are not...

Abrir o catálogo na página 5

your reliable partner Torque transducer

Abrir o catálogo na página 6

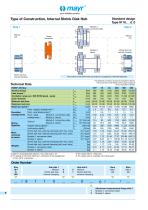

Sandwich Construction Side 1 O mayr your reliable partner Standard design Type 9110._ _330 Side 2 Torque transducer nJR Module 1, single joint Ef Module 2, single joint Shrink disk hub The shrink disk hub (side 1) with module 1 and module 2 with the shrink disk hub (side 2) Shrink disk hub external clamping are supplied as f'nished assemblies respectively. external clamping Technical Data The depicted connection screws are included in delivery. The screws for the left flange of the torque transducer are not included in delivery. 1) Valid for unchanging load direction, max. load cycle < 105...

Abrir o catálogo na página 7

Shrink disk hub, external clamping Shrink disk hub, internal clamping Module 1, connection plate* * Does not correspond to the former HBM ID. number 1-4411., (see page 11)

Abrir o catálogo na página 8

Module 2, connection plate o mayryour reliable partner Type 9110._ _010 Module 1, single joint / module 2, single joint for integrated measurement flange

Abrir o catálogo na página 9

Side 1 Side 2 Without hub Torque transducer Module 1, connection plate* nJ^ um The shrink disk hub (side 1) with module 1 is supplied as a finished assembly. * Does not correspond to the former HBM ID. number The depicted connection screws are included in delivery. 1-4411.011_ (see page 11) The screws for the left flange of the torque transducer Technical Data |ROBA®-DS Size 1) Valid for unchanging load direction, max. load cycle < 105 2) The values refer to 1 disk pack. 3) The values refer to couplings with 2 disk packs.

Abrir o catálogo na página 10

Shrink disk hub, external clamping Size * Does not correspond to the former HBM ID. number 1-4411.011 (see page below)

Abrir o catálogo na página 11

ROBA®-DS with conical connection On the ROBA®-DS with conical connection, the disk pack is connected via positive-locking with the hubs, the flanges or the sleeves. Externally conical bolts are pulled into conical bores in the attachment parts and the collar bushings of the disk packs by tensioning screws. The conical shape produces forces which widen the collar bushings and the attachment parts radially elastically, thus guaranteeing a backlash-free connection of the disk pack. For this backlash-free, positive locking connection, far lower screw tightening torques are required in...

Abrir o catálogo na página 12

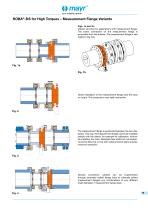

your reliable partner ROBA®-DS for High Torques – Measurement Flange Variants Figs. 1a and 1b: Classic structure for applications with measurement flange. The screw connection on the measurement flange is accessible from the outside. The measurement flange is tied rigidly to the hub. Direct installation of the measurement flange onto the input or output. This produces a very rigid connection. The measurement flange is positioned between the two disk packs. This way, the measurement flange can be de-installed radially with the sleeve, for example for calibration, without de-installing the...

Abrir o catálogo na página 13

your reliable partner Technical Explanations Coupling alignment Valid standards Exact coupling alignment reduces the reaction forces and therefore increases the lifetime of the coupling and the shaft bearing. This will ensure that the measurement line/drive line runs far more smoothly. Coupling characteristic values according to DIN 740, Part 2, Section 2.1. Stress dimensions according to DIN 740, Part 2, Sections 2.2 and 3 (dimensioning of the coupling for special applications). Coupling dynamically balanced according to ISO 1940. Permitted misalignment of the shaft ends General guidelines...

Abrir o catálogo na página 14

your reliable partner Product Summary Torque Limiters/Overload Clutches ❑❑ ❑❑ ❑❑ ❑❑ ❑❑ ❑❑ ❑❑ ❑❑ EAS®-Compact®/EAS®-NC/EAS®-smartic® Positive locking and completely backlash-free torque limiting clutches EAS®-reverse Reversing re-engaging torque limiting clutch EAS®-element clutch/EAS®-elements Load-disconnecting protection against high torques EAS®-axial Exact limitation of tensile and compressive forces EAS®-Sp/EAS®-Sm/EAS®-Zr Load-disconnecting torque limiting clutches with switching function ROBA®-slip hubs Load-holding, frictionally locked torque limiting clutches ROBA®-contitorque...

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos Chr. Mayr GmbH + Co. KG

-

Test stand technology

16 Páginas

-

Braking systems for vertical axes

16 Páginas

-

Steel industry

12 Páginas

-

Wind energy

24 Páginas

-

Stage Technology – Applications

20 Páginas

-

Elevator Brakes

24 Páginas

-

Machine Tool Components

20 Páginas

-

Robotics and Automation

20 Páginas

-

EAS®-Sp/Sm/Zr

24 Páginas

-

EAS®-smartic®

12 Páginas

-

EAS®-reverse

4 Páginas

-

EAS®-HTL

8 Páginas

-

EAS®-HT

28 Páginas

-

EAS®-HSE

16 Páginas

-

ROBA®-capping head

12 Páginas

-

EAS®-dutytorque

8 Páginas

-

ROBA®-contitorque

12 Páginas

-

ROBATIC®

60 Páginas

-

EAS®-axial

24 Páginas

-

ROBA®-drive-checker

4 Páginas

-

ROBA®-DS (heavy duty)

80 Páginas

-

ROBA®-ES

32 Páginas

-

smartflex®

8 Páginas

-

ROBA®-DS (steel)

80 Páginas

-

ROBA®-DS (servo)

80 Páginas

-

ROBA®-slip hub

24 Páginas

-

EAS®-compact® F

32 Páginas

-

EAS®-compact®

40 Páginas

-

ROBA®-takt

60 Páginas

-

ROBA®-SBCplus

4 Páginas

-

tendo®-PM

44 Páginas

-

ROBA®-secustop

8 Páginas

-

ROBA®-twinstop®

12 Páginas

-

ROBA®-duplostop®

12 Páginas

-

ROBA®-alphastop®

8 Páginas

-

ROBA®-topstop®

24 Páginas

-

ROBA-stop®-stage

4 Páginas

-

ROBA-stop®-S

12 Páginas

-

ROBA®-quick

60 Páginas

-

ROBA®-linearstop H

16 Páginas

-

ROBA®-linearstop E

16 Páginas

-

ROBA®-guidestop

32 Páginas

-

ROBA®-diskstop®

8 Páginas

-

ROBA-stop®-M Eco

4 Páginas

-

ROBA-stop-M servo pitch

8 Páginas

-

ROBA®-linearstop P

16 Páginas

-

ROBA-stop®-silenzio®

28 Páginas

-

ROBA-stop®-M

24 Páginas

-

ROBA®-servostop® Lean

12 Páginas

-

ROBA®-servostop® Cobot

12 Páginas

-

ROBA®-servostop® Classic

12 Páginas