Excertos do catálogo

Wheel Tractor Tractor Engine Cat® C15 with ACERT® technology Scraper Engine Cat C9 with ACERT technology

Abrir o catálogo na página 1

621G/627G Wheel Tractor Scrapers Responsible, productive earthmoving machines, built to last. Power Train – Engine Power Train – Transmission ✔ Electronically controlled Caterpillar engines with ACERT technology, modular radiator with 9 fins per inch, and an Electronic Control Module maximizes power to the cutting edge and exceptional haul road speed. pg. 4 ® ✔ Planetary powershift transmission delivers excellent load capability. Redesigned front and rear axles accommodate wider brake shoes and drums. The neutral coast inhibitor and programmable top gear reduce wear while increasing machine...

Abrir o catálogo na página 2

Operator Station Convenient control placement and a comfortable work environment are keys to high productivity. Features include Single Lever Implement Control, an air seat suspension and improved instrumentation. pg. 8 Superior structural design delivers state-of-the-art ride, capacity, and material control while assuring the durability and reliability customers expect from Caterpillar. pg. 10 Serviceability ✔ The latest electronic monitoring systems, grouped service points, and rugged Caterpillar components simplify maintenance and minimize downtime. New two-piece access doors open easily...

Abrir o catálogo na página 3

Power Train – Engine The new ACERT technology and proven components are electronically integrated to achieve new levels of performance and efficiency. ACERT Technology. The C15 and the C9 electronic engines with ACERT technology meet US EPA Tier 3 and EU Stage III emission regulations. ACERT technology reduces emissions during the combustion process by using advanced technology in the air and fuel systems, in conjunction with integrated electronics. Caterpillar meets emission regulations at the combustion source rather than recycling exhaust gases. C15 Tractor Engine. The Cat C15...

Abrir o catálogo na página 4

Engine Speed Lock. Allows the operator to maintain a given engine speed without using the accelerator pedal. This eliminates operator fatigue associated with holding the pedal down for extended periods of time. An on/off rocker switch enables the Speed Lock feature, and a lamp indicates the feature is active. Moving the rocker switch to the off position, or activating the service brakes or the retarder, disables the feature. Diagnostic Capability. Electronic Technician (Cat ET) is used to display real-time pressures, temperatures, fuel settings and diagnostic messages as well as a...

Abrir o catálogo na página 5

Power Train – Transmission Integrated electronics allows the machine to monitor the power train which reduces stress as well as provide a better ride to the operator. Retarder. The hydraulic retarder acts as an internal brake on the driveline that minimizes the need to apply service brakes. By engaging the retarder 3 to 4 seconds before the machine traverses a downhill grade, the operator can reduce wear on the service brakes and enhance machine control. Differential Control. Electronic differential lock on the tractor helps prevent the drive wheels from spinning in poor underfoot...

Abrir o catálogo na página 6

Electronic Controls Instant response optimizes machine performance, and advanced diagnostic capabilities maximize machine availability. Easy Access Diagnostics. Diagnostic codes are accessible through the EMS main display module, via the Electronic Technician (Cat ET). This offers a head start on problem solving, with a radio call often providing the service technician with the knowledge of which tools, troubleshooting guides, and possibly even replacement parts to bring to the machine. Greater Reliability. The Caterpillar EUI system has fewer moving parts than mechanical unit injection and...

Abrir o catálogo na página 7

Operator Station Redesigned for enhanced operator comfort and productivity. Multi-Adjustable Seat. The Cat Comfort Cloth Seat has an adjustable seat and armrests for maximum operator comfort. • Swivels and locks in four positions (0º, 10°, 20° and 30º) providing the optimum operating position in the cut or on the haul. Fore/aft and vertical height adjustment to accommodate various sized operators. Seat Suspension. The seat suspension redefines the ride of scrapers. It features a high performance air shock absorber with its own air compressor. Standard Air Conditioning. Gives the operator a...

Abrir o catálogo na página 8

Visibility. Hood and front shroud width increased to accommodate the low emission engine, the air-to-air aftercooler (ATAAC), ether starting aid, and lights. Hood corners are sloped to maintain the same level of visibility as the E-Series. Single Lever Implement Control. Simple and easy to operate, the joystick enhances the productivity of operators of all skill levels. Requires less force to control the critical scraper functions and requires less lever travel. Grab handle/ hand rest next to joystick controller so operator has a place to rest hand while on the haul and return roads. 1)...

Abrir o catálogo na página 9

Structures Superior structural design and construction optimize performance and reliability. Cushion Hitch. The electronically actuated cushion hitch incorporates a parallelogram-type linkage for exceptional strength with nitrogen accumulators to deliver a smooth ride for enhanced operator comfort. Load cylinder Hitch castings Scraper gooseneck Nitrogen accumulators Orifice Oil from tractor hydraulic system Leveling valve Free floating pistons steel castings are used extensively to eliminate many welded joints and increase strength leveling valve automatically centers piston in cylinder for...

Abrir o catálogo na página 10

Scraper Bowl Designed for optimum loading, material retention and ejection. Redesigned Bowl. Excellent productivity with a 10% increase in bowl capacity, improved draft arm protection, and better load retention. Low-profile design of the bowl offers less resistance to incoming materials, while cellular construction adds strength and dent resistance to bowl sides and floor. Bulldozer Ejection System. Combines constant spreading control while minimizing carryback material. A spill guard on the ejector (standard on 627G, optional on 621G) helps retain material and keep it from spilling over...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos Caterpillar Global Mining

-

D9 DOZER

20 Páginas

-

745

28 Páginas

-

725C2

28 Páginas

-

Cat ® 621K

4 Páginas

-

D9T

20 Páginas

-

D8T

20 Páginas

-

735B Articulated Truck

20 Páginas

-

725 Articulated Truck

20 Páginas

-

777D

28 Páginas

-

775G

32 Páginas

-

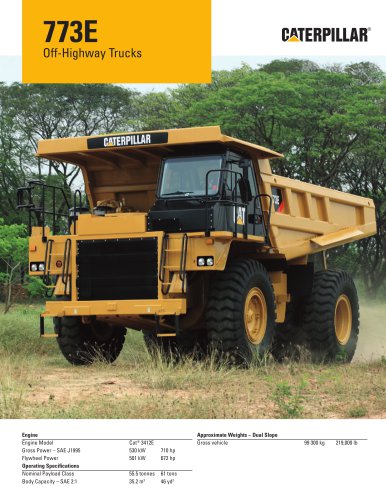

773E

24 Páginas

-

772G

28 Páginas

-

772

32 Páginas

-

770

32 Páginas

-

16M

24 Páginas

-

14M

28 Páginas

-

795F AC

24 Páginas

-

793D

32 Páginas

-

789D

28 Páginas

-

789C

28 Páginas

-

HW300

16 Páginas

-

785D

24 Páginas

-

AEXQ1170 ShovelsBrochure

32 Páginas

-

D11T/D11T CD

28 Páginas

-

D10T

20 Páginas

-

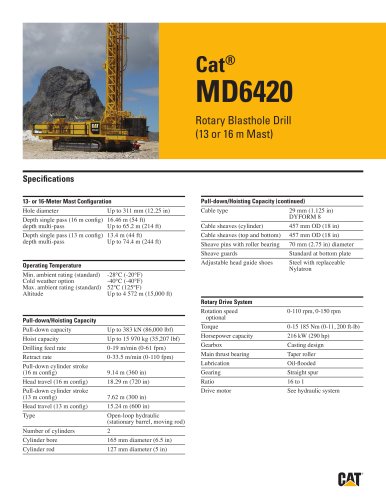

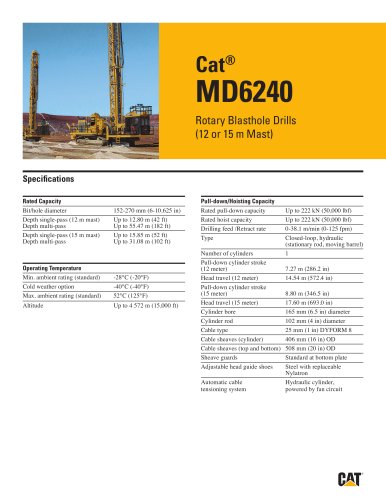

MD6240 Rotary Drill

28 Páginas

-

Cat ® Rock Flow System

2 Páginas

-

LHD Vehicles Product Line

8 Páginas

-

Pre-Engineered Belt Terminal Groups

4 Páginas

-

Mining Truck (797F)

28 Páginas

-

Motor Grader (16M)

24 Páginas

-

Off-Highway Truck (773G)

32 Páginas

-

Off-Highway Truck (777G)

36 Páginas

-

Open Bowl Scraper (627H)

20 Páginas

-

Open Bowl Scraper (623H)

20 Páginas

-

Open Bowl Scraper (631G)

24 Páginas

-

Open Bowl Scraper (621H)

20 Páginas

-

Open Bowl Scraper (657G)

24 Páginas

-

Longwall Mining Equipment

12 Páginas

-

LHD Vehicles

8 Páginas

-

CTS Drive Systems

8 Páginas

-

Cat® Trucks: The ONE for Mining

28 Páginas

-

Cat® Mining Motor Grader: Smart Grading

20 Páginas

-

Cat® Hauling Systems - More Ways to Work

11 Páginas

-

Belt Systems - Underground Flex Pal

8 Páginas

-

Belt Systems - Underground

12 Páginas

-

Armored Face Conveyors (AFCs)

12 Páginas

-

Longwall Automation

12 Páginas

-

Cat® track drills MD5150

28 Páginas

-

Electric Rope Shovels 7182

3 Páginas

-

Cat® track drills MD5125

4 Páginas

-

Cat® track drills MD5050 T

4 Páginas

-

Cat® track drills MD5090

4 Páginas

-

Cat® track drills MD5075

4 Páginas

-

Electric Rope Shovels 7295

3 Páginas

-

Electric Rope Shovels 7395

3 Páginas

-

Electric Rope Shovels 7295 HD

3 Páginas

-

Cat® track drills MD5050

4 Páginas

-

Cat® Rotary drills MD6750

4 Páginas

-

Cat® Rotary drills MD6640

4 Páginas

-

Electric Rope Shovels 7495 HD

3 Páginas

-

Electric Rope Shovels 7495

3 Páginas

-

Cat® 8750 DRAGLINE RANGE

28 Páginas

-

Master Idler

399 Páginas

-

Electric Rope Shovels 7495 HF

3 Páginas

-

Cat® 8200 DRAGLINE RANGE

2 Páginas

-

Cat® MD6540 Rotary Blasthole Drill

8 Páginas

-

Cat® MD6290 Rotary Blasthole Drills

8 Páginas

-

Cat® 8200-127 Dragline

2 Páginas

-

Cat® 8200-126 Dragline

2 Páginas

-

Cat® 8200-125 Dragline

2 Páginas

-

Cat® 8200-124 Dragline

2 Páginas

-

Cat® 8200-123 Dragline

2 Páginas

-

Cat® 8200-113 Dragline

2 Páginas

-

Engineered Class Conveyor Pulleys

4 Páginas

-

Engineered Belt Terminal Groups

4 Páginas

-

Belt systems and belt products

8 Páginas

-

740B EJ articulated track

24 Páginas

-

740B articulated track

20 Páginas

-

730 ejector articulated track

20 Páginas

-

730 articulated track

20 Páginas

-

Feeder Breakers

4 Páginas

-

Belt Systems & Belt Products

8 Páginas

Catálogos arquivados

-

Draglines

8 Páginas

-

988H Wheel Loader

24 Páginas

-

844H Wheel Dozer

20 Páginas

-

Scoops

8 Páginas

-

Face Haulers

12 Páginas

-

Continuous Miners

8 Páginas

-

Longwall Shearers

16 Páginas

-

Roof Support Carriers

12 Páginas

-

Roof Support Systems

8 Páginas

-

Automated Plow Systems

12 Páginas

-

Jumbo Drills

12 Páginas

-

Rotary Blasthole Drills

8 Páginas

-

Hydraulic Track Drills

8 Páginas

-

Hydraulic Shovels

12 Páginas

-

Highwall Mining System

8 Páginas

-

Electric Rope Shovels

12 Páginas

-

Surface Belt Structure

8 Páginas