Excertos do catálogo

Powerful Solutions for Welding and Cutting Automation Custom Configurations From Standard Components Aluminum Rigid Rail (ARR) for all position straight line applications (Page 2) Bent Rigid Rail (BRR) & Ring Rails for circumferential applications (Page 4-5) Aluminum Semi-Flex Rail (AFR) for large diameter applications down to a minimum radius of 15' (5 m) (Page 2) Hi-Flex Rail (FMD) for various circumferential and irregular surface applications down to 30" (760 mm) radius (Page 2) Bug-O Systems offers rail for a variety of applications. Each type of rail requires a corresponding carriage and magnets or vacuum cups. Bug-O rail is lightweight and portable. When attached to the work with magnets or vacuum cups the rail can be used in any plane or position. The rail is pre-drilled for easy installation on a fixture. Choose the appropriate rail and attachments for your application. Bug-O Systems is guided by honesty, integrity and ethics in service to our customers and in all we do. A DIVISION OF WELD TOOLING CORPORATION 280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 PHONE: 412-331-1776 http://www.bugo.com FAX: 412- 331- 0383

Abrir o catálogo na página 1

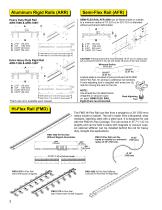

Aluminum Rigid Rails (ARR) Heavy Duty Rigid Rail ARR-1080 & ARR-1085* A Semi-Flex Rail (AFR) SEMI-FLEX RAIL AFR-3000 can be flexed inside or outside to a minimum radius of 15' (5.0 m) or 30' (10.0 m) diameter without permanent deformation. CAUTION: Flexing beyond the recommended 15'-0" (5.0 m) radius may put a permanent bend in the rail and break off some of the rack screws. Extra Heavy Duty Rigid Rail ARR-1250 & ARR-1200* A A splice plate is mounted at one end of each AFR-3000 Semi-Flex Rail, for joining to additional rail sections. A rack-adjusting tool is supplied with every two (2)...

Abrir o catálogo na página 2

Magnets, Rail Alignment Tools and Vacuum Accessories A Minimum of six (6) magnets or vacuums cups are required per rail for all out of position applications. Eight (8) are recommended. For Aluminum Rigid Rail R.E. On/Off Magnet ARM-2010 ARM-2010-HH* Holding Power 250 lb. (113 kg) Spacer ARM-2015 Use with ARM-2010 only Swivel Magnet w/ Release ARM-2325 Holding Power 250 lbs. (113 kg) Fixed Magnet w/ Release ARM-2265 Holding Power 200 lbs. (91 kg) Magnet Plate, Short ARM-2248 Holding Power 200 lbs. (91 kg) Rail Alignment Tool ARR-1090 Gauging device for rapid alignment of rails to joint R.E....

Abrir o catálogo na página 3

Bent Rigid Rail (BRR) BRR rail is used for circumferential applications. The rail can be ordered either as a complete ring or as individual sections. When ordering, specify inside or outside work diameter, method of mounting (magnets, vacuum cups or bolts) and if a complete circle is required. The mounting method will be taken into consideration to determine actual rail radius. On large work diameters individual sections of rail can “Leapfrog” around the vessel. Use at least four (4) magnets or vacuum cups on each piece of BRR-1180. Pieces of Rail Needed to Form Complete Ring Maximum...

Abrir o catálogo na página 4

Rapid Installation Rail Bug-O Piper Steel Rail (PSR) & Bent Rigid Rail (BRR) are made to order, to fit specific diameters. They are designed for rapid installation and movement between weld locations. To insure proper fit, confirm exact work piece outside diameter when ordering. Features: • Quick attach ring rail mounts quickly and easily to the pipe • Fast setup • Spacer bars adjust and center the ring to the pipe surface • Fast removal • Powerful latches lock the rail into position • Lightweight and easy to move from pipe to pipe • Machine mounts quickly to the rail using standoffs and a...

Abrir o catálogo na página 5

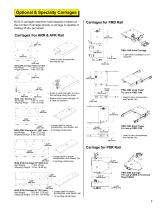

Carriages BUG-O carriages maximum load capacity is based on the number of carriage wheels. A carriage is capable of holding 25 lbs. per wheel. For Aluminum Rigid Rail For Modular Drive And Universal Bug-O-Matic • Releasable (can be installed anywhere along the track) 8.00" (203 mm) MPD-1065 Releasable Carriage Net Weight: 7.75 lbs. (3.52 kg) Shipping Weight: 9 lbs. (4.09 kg) For Bent Rigid Rail • Mounts a DC IV Drive Unit, Modular Drive Unit and Universal Bug-O-Matic • Releasable (can be installed anywhere along the track) • Runs on straight or BRR Ring Rail FMD-1150 Hi-Flex Carriage for...

Abrir o catálogo na página 6

Optional & Specialty Carriages BUG-O carriages maximum load capacity is based on the number of carriage wheels. A carriage is capable of holding 25 lbs. per wheel. • Used to carry accessories, wire feeder, etc. BUG-2205 Carriage Trailer w/ Hitch Net Weight: 6 lbs. (2.72 kg) Shipping Weight: 8 lbs. (3.62 kg) 8" (203 mm) • Used when oscillation is not required • Knob is used manually to move the carriage along the track • Bottom knob locks carriage to a fixed rail position MUG-1140 Spotting Car Net Weight: 6 lbs. (2.72 kg) Shipping Weight: 8 lbs. (3.62 kg) FMD-1090 Long Trailer For use w/...

Abrir o catálogo na página 7

Fixture Building Cross Beam Assemblies Longitudinal rail sections are fabricated from rectangular steel tubing with ARR-1080 or ARR-1085 HD Rigid Rail mounted on each side. Two (2) standard lengths are available and these sections can be joined together to provide the length required. Splicing Plates BUG-1053 Splicing Plates are used with the BUG-1040-1 and BUG-1040-2 longitudinal rail sections. Order one splice plate per joint. Vertical columns for BUG-1040-1 or BUG-1040-2 longitudinal rail sections are available in three lengths. BUG-1040-1 4' (1.18 m) long BUG-1040-2 8' (2.37 m) long...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos BUG-O SYSTEMS

-

UNI-BUGS

4 Páginas

-

AUTOMATIC ARC GOUGING SYSTEM

4 Páginas

-

FIXTURING EQUIPMENT

4 Páginas

-

PIPER-PLUS PIPE WELDING SYSTEM

12 Páginas

-

STIFFENER WELDERS

4 Páginas

-

SUPPORTS AND ACCESSORIES

4 Páginas

-

PROGRAMMABLE CIRCLE BURNERS/WELDERS

16 Páginas

-

BEVELERS

2 Páginas

-

GO-FER® IV

6 Páginas

-

AUTOMATIC HEIGHT CONTROL

2 Páginas

-

KBUG REMOTE SYNCING INSTRUCTIONS

1 Páginas

-

Zipper Welder

4 Páginas

-

K-BUG 5050/K-BUG 6050

4 Páginas

-

Arc Gouger

4 Páginas

-

FixturesEquipment

4 Páginas

-

Tank Fabrication

8 Páginas

-

DC Speed Weaving Kit

2 Páginas

-

Supports & Accessories

4 Páginas

-

Programmable Shape Machine

4 Páginas

-

MDS Programmable Shape Machine

6 Páginas

-

DC-IV Tractor

2 Páginas

-

Trac-Bug

2 Páginas

-

Uni-bug III

4 Páginas

-

Unibug II

4 Páginas

-

Speed Weaver II

4 Páginas

-

Beam Bug III

4 Páginas

-

Universal Bug-o-matic

4 Páginas

-

Piper Plus Pipe Welding System

12 Páginas

-

Piper-Bug Pipe Welding System

8 Páginas

-

Con-o

2 Páginas

-

Cir-o

2 Páginas

-

Hob-o

2 Páginas

-

General Catalogue

24 Páginas

-

Modular Drive System

16 Páginas

-

Weld Backings

2 Páginas

-

K-BUG 2000 Dual Torch Fillet Welder

4 Páginas

-

Portable Plate Beveler

2 Páginas

-

Hob-o Blind Area Kit

2 Páginas

-

Torches

2 Páginas

-

Heavy Duty Tool Positioning System

4 Páginas

-

Carriages Rails & Attachments

8 Páginas

-

Go-fer III

6 Páginas

-

MM-1 Programmable Pipe Cutter

6 Páginas

-

Programmable Gantry

4 Páginas

-

Auto Height Control

2 Páginas

-

TAR-GIT

2 Páginas

-

Pitbull Beveler

2 Páginas

-

Automated Circle Burning and Welding

16 Páginas

-

Stiffener Welder

4 Páginas

-

DC General Welding Kit

2 Páginas

-

All Position Overlay System

2 Páginas

-

Heavy Duty Sub-arc Tractor

2 Páginas

-

Pipe-Bug

4 Páginas

Catálogos arquivados

-

Sprinkler Brochure

6 Páginas

-

Weld Backings

2 Páginas