Website:

Balluff GmbH

Website:

Balluff GmbH

Grupo: Balluff

Excertos do catálogo

Semiconductor industry PRECISION FOR SEMICONDUCTOR, SOLAR AND DISPLAY MANUFACTURING

Abrir o catálogo na página 1Balluff in the semiconductor industry WE ARE AT HOME IN MANY DIFFERENT SECTORS

Abrir o catálogo na página 2Balluff in the semiconductor industry WE SUPPORT YOUR WAFER PROCESSING AND DISPLAY PRODUCTION VACUUM APPLICATION WAFER HANDLING WAFER PROCESSING Mobile Communication – Internet of Things – Smart Factory – Smart Home. What all these current developments have in common is digitization. With semiconductors as their heart. This makes the semiconductor industry a pathfinding one. But the change to digital places demands on the industry at the same time. For example chips need to provide ever greater performance. Chip pro uction itself is a highly d complex, technologically extremely demanding...

Abrir o catálogo na página 3CONTENTS Exact positioning without contact 8 CARRIER HANDLING High precision even between the process steps 12 WAFER HANDLING We assist in process security 18 VACUUM APPLICATION Reliable processing in chemical surroundings 22 WAFER PROCESSING High precision and communications expertise

Abrir o catálogo na página 4Carrier handling EXACT POSITIONING WITHOUT CONTACT Balluff systems support precise and efficient carrier handling – whether it is an FOUP or SMIF pod. When the carrier is transported fully automatically our systems monitor the movements of the AMHS. With extreme reliability, both over short distances with RGVs or long distances with OHVs. At the same time our non-contact systems provide exact positioning. Your wafers are reliably transported for each and every processing step. Abrasion and splitting are not a problem. Balluff systems also provide consistent traceability. They ensure that...

Abrir o catálogo na página 5Solutions for carrier handling CHECKING FOR CARRIER PRESENCE With BOH photoelectric sensors RELIABLE CARRIER TRACKING With BVS vision sensors CONTINUAL DETECTION OF THE AMHS POSITION With BML magnetic encoder systems CHECKING END POSITION OF THE AMHS With BES inductive sensors To detect the presence of a carrier on a load port, our space-saving through-beam and diffuse sensors are ideal. Their especially flat construction allows them to be ideally integrated. The minimal installation surface on the load port which is often no larger than the transport box, can then be simply maintained....

Abrir o catálogo na página 6Wafer handling HIGH PRECISION EVEN BETWEEN THE PROCESS STEPS When it comes to wafer handling in the EFEM module, such as on the end effector or the pre-aligner, Balluff gives you high precision. Only extreme accuracy allows wafers to be exactly positioned and reliably transported for each individual processing step. Our sensors and systems are available in compact form factors to easily meet demanding requirements for machine integration. When conditions are especially challenging – after all, every end effector is different – we can also tailor our technology to your individual...

Abrir o catálogo na página 7Solutions for wafer handling 5 7 2 1 DETECTING ROBOT POSITION With BML magnetic encoder systems MONITORING ROBOT ROTATION With BML magnetic encoder systems Are you using multiple load ports? Or multiple process chambers? Then use our high-precision magnetic encoder systems to reliably monitor the movement of your robot units. These non-contact distance measuring systems continuously monitor the robot position. And the magnetic tape can be trimmed to exactly the length you need. This means you can use the system for modules with varying numbers of load ports. To position the end effector of...

Abrir o catálogo na página 8WAFER PRE-ALIGNMENT With BLA light arrays CHECK FOR WAFER PRESENCE ON END-EFFECTORS With BOH photoelectric sensors CHECK FOR WAFER PRESENCE ON END-EFFECTORS With BCS capacitive sensors CHECKING WAFER POSITION ON THE END EFFECTOR With BES inductive NAMUR sensors RELIABLE WAFER MAPPING With BOH photoelectric sensors TRACKING WAFER FRAMES With the BVS vision sensors Bring your wafers to the process chamber perfectly aligned by exactly positioning them in pre-aligner. We offer an outstanding solution for optical pre-aligners: a high-resolution light array with extraordinary homogeneity....

Abrir o catálogo na página 9Vacuum application WE ASSIST IN PROCESS SECURITY Sensors from Balluff with their extraordinary design features let you use them directly in a vacuum. For example during alignment on the fly when the wafer is centered in the vacuum lock or when you need to check it for presence. We offer thread-in versions with a sealing function as well as sensors for installation directly in high vacuum. Their signals are reliably brought out through electrical cables via a cable fitting. And take special note: Since we use outgassing-optimized materials for the sensor, your process remains secure. If...

Abrir o catálogo na página 10Solutions for vacuum applications CENTERING WAFERS With BOH photoelectric sensors DETECTING WAFER PRESENCE With BOH photoelectric sensors CHECKING WAFER PRESENCE With BOH photoelectric sensors You can reliably ensure alignment of the wafer on-the-fly using two Micromote through-beam sensors. Their high-precision signals make it possible to calculate the offset for the ideal line when the switching for both through-beam sensors is not simultaneous. Due to our Microspot technology, you can correct the wafer, since it precisely detects the sharp wafer edges. To ensure a reliable process you...

Abrir o catálogo na página 11Wafer processing RELIABLE PROCESSING IN CHEMICAL SURROUNDINGS To meet the special challenges of semiconductor production, Balluff offers you optimal solutions for processes in wet chemistry. Special PTFE housings let you monitor levels – such as when etching, cleaning the wafers or coating and developing in lithography. Our temperature sensors then ensure that the process temperature is correct. Because these contacting sensors let you reliably monitor temperatures in wafer processing. With our sensors you also control the valve stroke, so that you can produce homogeneous and ideal coats in...

Abrir o catálogo na página 12Solutions for wafer processing NON-CONTACT DETECTION OF LEVELS THROUGH THE CONTAINER WALL With BCS capacitive sensors MONITOR LEVELS WITHOUT CONTACT ON BY-PASS TUBES With BCS capacitive sensors In wet chemistry you can ensure a frictionless process chain by using our capacitive sensors to verify the ideal level for acid, base and ultrapure water tanks. These reliably detect the level through up to 10 mm thick glass and plastic vessel walls. For highly conductive media such as acids, use our capacitive high-end sensors, which also mask out foam and build-up. You can also prevent overflow of...

Abrir o catálogo na página 13Todos os catálogos e folhetos técnicos Balluff GmbH

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Páginas

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Páginas

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Páginas

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Páginas

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Páginas

-

PRODUCTS + NEWS

25 Páginas

-

THE ARCHITECTS OF SMART MANUFACTURING

12 Páginas

-

HIGH PROCESS SECURITY AT EVERY STEP

19 Páginas

-

SOLUTIONS FOR LEVEL DETECTION

2 Páginas

-

SENSORS AND SYSTEMS FOR HIGH EFFICIENCY

29 Páginas

-

UP THE TEMPO WHILE IMPROVING QUALITY

28 Páginas

-

GUIDED CHANGEOVER SOLUTION

3 Páginas

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Páginas

-

SOLUTIONS FOR FLUID POWER TECHNOLOGY

21 Páginas

-

MOBILE EQUIPMENT

21 Páginas

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Páginas

-

TAILOR-MADE QUALITY

5 Páginas

-

WE MONITOR YOUR MACHINES

10 Páginas

-

PACKAGING, FOOD AND BEVERAGE

76 Páginas

-

WE SPEAK IO-LINK. ON A GLOBAL SCALE

31 Páginas

-

MANAGING ALL YOUR DATA

6 Páginas

-

MAGNETIC FIELD SENSORS

7 Páginas

-

Balluff products and services

94 Páginas

Catálogos arquivados

-

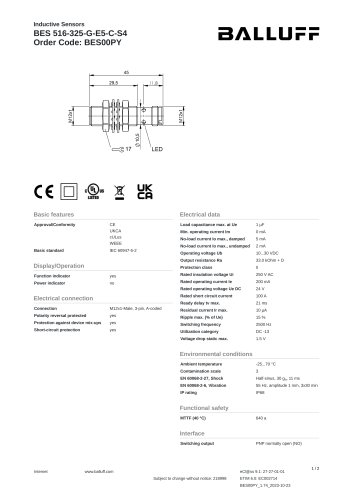

BES00PY

2 Páginas

-

BES008L

2 Páginas

-

BES02NC

2 Páginas

-

BES01ZN

2 Páginas

-

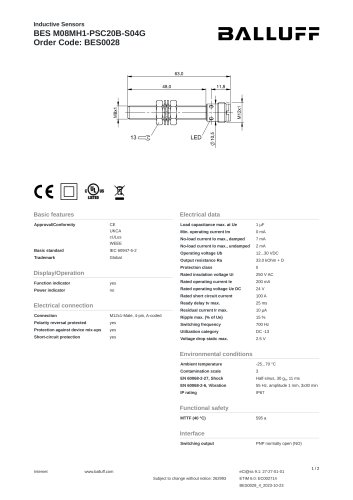

BES0028

2 Páginas

-

BES05F9

2 Páginas

-

BES054Z

2 Páginas

-

BES0086

2 Páginas

-

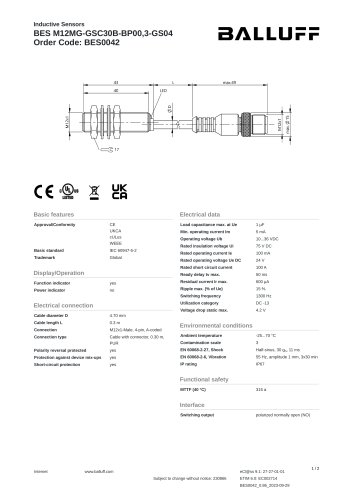

BES0042

2 Páginas

-

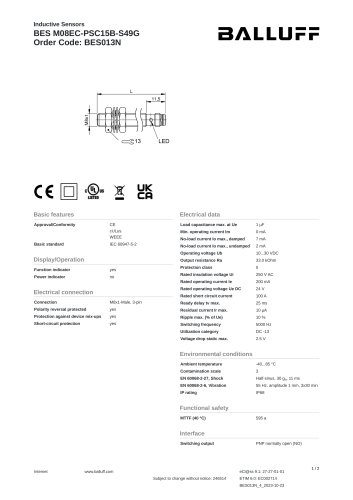

BES013N

2 Páginas

-

BES00H4

2 Páginas

-

BES003P

2 Páginas

-

BES00HC

2 Páginas

-

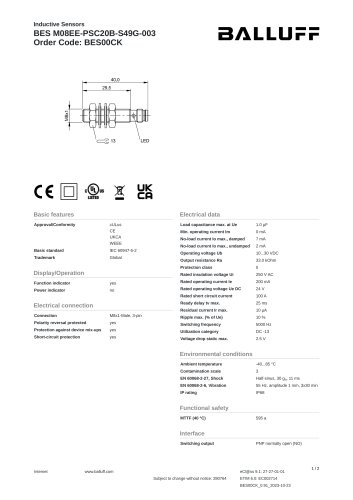

BES00CK

2 Páginas

-

BES01ZW

2 Páginas

-

BES00EF

2 Páginas

-

BES00HF

2 Páginas

-

BES00P7

2 Páginas

-

BES0068

2 Páginas

-

BES060T

2 Páginas

-

QUALITY DOWN TO THE LAST DETAIL

94 Páginas

-

OUR HEART BEATS – FOR INDUSTRY 4.0

4 Páginas

-

OPENING NEW PERSPECTIVES

13 Páginas

-

BALLUFF TEST CAMPUS

15 Páginas