Excertos do catálogo

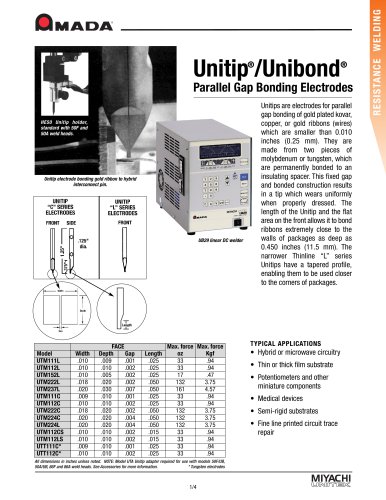

Parallel Gap Bonding Electrodes HE50 Unitip holder, standard with 50F and 50A weld heads. Unitip electrode bonding gold ribbon to hybrid interconnect pin. All dimensions in inches unless noted. NOTE: Model UTA Unitip adapter required for use with models 50F/UB, 50A/UB, 86F and 86A weld heads. See Accessories for more information. * Tungsten electrodes Unitips are electrodes for parallel gap bonding of gold plated kovar, copper, or gold ribbons (wires) which are smaller than 0.010 inches (0.25 mm). They are made from two pieces of molybdenum or tungsten, which are permanently bonded to an insulating spacer. This fixed gap and bonded construction results in a tip which wears uniformly when properly dressed. The length of the Unitip and the flat area on the front allows it to bond ribbons extremely close to the walls of packages as deep as 0.450 inches (11.5 mm). The narrower Thinline “L” series Unitips have a tapered profile, enabling them to be used closer to the corners of packages. TYPICAL APPLICATIONS • Hybrid or microwave circuitry • Thin or thick film substrate • Potentiometers and other miniature components • Medical devices • Semi-rigid substrates • Fine line printed circuit trace repair RESISTANCE WELDING

Abrir o catálogo na página 1

RESISTANCE WELDING UNIBOND ELECTRODES Unibond electrodes are used for parallel gap bonding and reflow soldering. Generally, RWMA2 copper Unibond electrodes are used with resistive and/or hard materials such as gold plated kovar and nickel. Molybdenum Unibond electrodes are used for bonding conductive or soft materials such as copper or gold. The face of a Unibond electrode is 0.020 inches (0.5 mm) wide by 0.030 inches (0.75 mm) deep. In unfixtured applications, this limits their use to bonding ribbons (wire) which are at least 0.010 inches (0.25 mm) wide because of the limited visibility....

Abrir o catálogo na página 2

To minimize operator positioning errors, use an electrode tip that has a larger face area than the part being welded. Small variations in electrode position have no effect on the weld quality because the electrode tip contact area stays constant. Longer electrode tip life, less electrode sticking, and reduced frequency of electrode cleaning are added benefits of using the largest possible electrode tip face. When using a parallel gap electrode that is larger than the part being welded, the electrode gap must be perpendicular to the part. Figure 5 shows a large Unitip electrode tip centered...

Abrir o catálogo na página 3

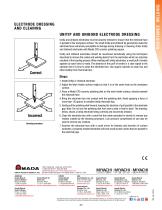

RESISTANCE WELDING ELECTRODE DRESSING AND CLEANING UNITIP AND UNIBOND ELECTRODE DRESSING Unitip and Unibond electrodes must be properly dressed to ensure that the electrode face is parallel to the workpiece surface. The small Unitip and Unibond tip geometries make the electrode faces extremely susceptible to damage during dressing or cleaning. Dress Unitip and Unibond electrodes with Model CPD ceramic polishing square. Unitip and Unibond electrodes should be resurfaced periodically using the techniques described to remove the oxides and welding debris from the electrodes which are naturally...

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos AMADA WELD TECH Inc.

-

TC-W100A

2 Páginas

-

MEA-100B

2 Páginas

-

MIB-300A/600A

2 Páginas

-

CD-A125A CD-A300A CD-A1000A

2 Páginas

-

Desktop Series ACF Laminating

2 Páginas

-

Hot Application Wire Stripping

4 Páginas

-

Rotary Dial Index Systems

2 Páginas

-

AMADA WELD TECH

24 Páginas

-

HF-2700A / HF-2500A

4 Páginas

-

CD-V Series

2 Páginas

-

MD-A10000A/ MD-B5000A

2 Páginas

-

ISQ Series

3 Páginas

-

IPB-5000A-MU

2 Páginas

-

MFP60 for aws3

2 Páginas

-

MFP25 FRO AWS3

2 Páginas

-

Series 320

2 Páginas

-

newhorizon

3 Páginas

-

F120, F160, FD120

4 Páginas

-

KN-II Series

2 Páginas

-

MH Weld Head Range

4 Páginas

-

Accessries

9 Páginas

-

Laser Microfabrication

2 Páginas

-

ML-5120A

2 Páginas

-

LMWS Laser Marking Workstation

2 Páginas

-

Systems

16 Páginas

-

ML-5120

2 Páginas

-

DC29-UB29-UB29A

4 Páginas

-

LF Series Lasers

2 Páginas

-

SA2200 Dual Oven

2 Páginas

-

Laser Tube Cutting Systems

2 Páginas

-

Heat Staking

2 Páginas

-

Seam Laser Welder - 150W

2 Páginas

-

Systems Datasheet

16 Páginas

-

Fiber Laser Welders - 100W - 500W

2 Páginas

-

Micro Spot Laser Welder - LW5AM

2 Páginas

-

Pulsed Micro TIG Welder - MAWA-300A

2 Páginas

-

Micro TIG Accessories Brochure

4 Páginas

-

resistance welding Fundamentals

8 Páginas

-

Resistance Welding Accessories

9 Páginas

-

AX5000 Glovebox

2 Páginas

-

MX2000 Glovebox

2 Páginas

-

Alpha Series Glovebox Systems

2 Páginas

-

Benchmark AF8500 / AF 1250

2 Páginas

-

Pulsed-Heat Hot-Bar

10 Páginas

-

Benchmark SM8500

2 Páginas

-

vacuum bakeout oven

2 Páginas

-

Interposer Module

2 Páginas

-

UV Laser Marking Systems

2 Páginas

-

CO2 Laser Marking Systems

2 Páginas

-

Sigma XY Fiber Laser Cutting System

2 Páginas

-

Linear DC Weld Controls - MDA-10000A

2 Páginas

-

Portable Weld Checker - MM-315A

8 Páginas

-

Fiber Laser Micro Welders

2 Páginas

-

Green Micro Spot Laser Welder - 5W

2 Páginas

-

Sigma Laser Tube Cutter

2 Páginas

-

Laser Marker Motion

2 Páginas

-

Macro Spot Laser Welders - 5 to 25W

2 Páginas

-

High Force Weld Heads - MH Series

4 Páginas

-

Nd:YVO4 'Green' Laser Marker - 5w

2 Páginas

-

Laser Welding Gloveboxes

2 Páginas

-

Thermocouple Welder - TCW

2 Páginas

-

Desktop Galvo Laser Welding Systems

2 Páginas

-

Laser Accessories

7 Páginas

-

Alpha Series

2 Páginas

-

MX-2000 Glovebox Technical

2 Páginas

-

AX-5000 Glovebox

2 Páginas

-

Benchmark Accessories

9 Páginas

-

Thin Line Weld Heads

8 Páginas

-

Uniflow 4

2 Páginas

-

Pulsar

2 Páginas

-

Laser Microfabrication System

2 Páginas

-

LMF Series Fiber Laser Markers

4 Páginas

-

LMC1 Laser Marker Motion

2 Páginas

-

LW300-600A

2 Páginas

-

LW50A-70-150A

2 Páginas

-

LW5-15-25A

2 Páginas

-

LF Series

2 Páginas

-

50 Series Weld Heads

4 Páginas

-

MH Series Weld Heads

4 Páginas

-

MG3

12 Páginas

-

MG3 Hot Bar Monitoring

3 Páginas

-

Hot Bar Process Calibration Tools

2 Páginas

-

Sarcon and Kapton Modules

2 Páginas

-

Thin-line

8 Páginas

-

IS series

2 Páginas

-

ISB-300 A

2 Páginas

-

Accessoires

9 Páginas

-

DC25, UB25

4 Páginas

-

Inverter Spot Weld Control - ISQ

4 Páginas

-

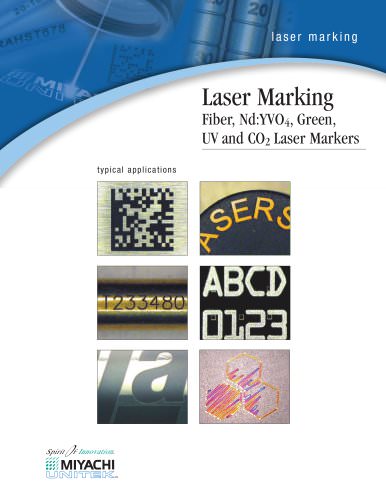

Laser Marking & Engraving Systems

2 Páginas

-

Fiber Laser Micro Welding Systems

2 Páginas

-

Nd:YV04 UV Laser Marker Systems

2 Páginas

-

Fine Laser Cutting Datasheet

4 Páginas

-

laser markers and marker systems

16 Páginas

-

Bonding Heads

2 Páginas

-

MG3 UNIQUE PROCESS MONITORING

12 Páginas

-

Premium Hot Bar Monitoring System

3 Páginas

-

Process Calibration Tools

2 Páginas

-

LaserCuttingSystems_Cut

4 Páginas

-

Pincer Weld Head - MFP-Z

3 Páginas

-

Color Digital Weld Monitor - MG3

4 Páginas

Catálogos arquivados

-

Fiber Laser Cutting System - 5 Axis

2 Páginas

-

Inverter Spot Weld Control - IS-120B

2 Páginas