Excertos do catálogo

HEAT SEAL BONDING

Abrir o catálogo na página 1

CONTENTS Applications The Fastest Path from Application to Production 5-Axis Glovebox System High Volume Workstation Dual Wavelength Welding System Inline Workstation/System Laser Marking System Laser Cutting System Delta Series Seam Sealing System Projection Welding System LCD Repair Workstation System Options Company Profile Amada Miyachi America is the only major supplier to offer turnkey laser, resistance welding and heat seal bonding systems, providing the fastest path from application concept to full production. We stand behind every system built to solve each manufacturing challenge,...

Abrir o catálogo na página 2

LASER & RESISTANCE WELDING Laser welding is a fast and efficient non-contact process which joins two similar or certain dissimilar metals together, requiring access to the weld zone from just one side. With precise control of laser parameters, high quality spot and seam welding is possible for both fine and penetration applications. Resistance welding is a cost-effective solution that can join a wide variety of materials, offers self-clamping parts and features closed-loop feedback for precise process control. LASER MARKING Laser marking and engraving provides a fast, clean and efficient...

Abrir o catálogo na página 3

THE FASTEST PATH FROM APPLICATION TO PRODUCTION APPLICATION QUALIFICATION & TESTING Our experienced applications engineers can provide instant feedback on sample feasibility with reference to material selection, joint geometries and part fit up. Sample evaluation in our labs is aligned to your specific application requirements and budget. Each evaluation provides clear and detailed recommendations for the best suited power supply, as well as feedback on suitability for the proposed manufacturing environment. LASER/SYSTEM SPECIFICATION With in-house expertise in enclosures, tooling, motion,...

Abrir o catálogo na página 4

Every job is assigned a dedicated project manager system engineer who handles the project from concept to completion. Our partnership approach with customers ensures that expectations are fully understood, and any changes can be efficiently managed. INSTALLATION, TRAINING & SUPPORT Installation and training is a critical part of the process, ensuring the capabilities and operation of the system are fully understood at both engineering and production levels. Every system is installed at the customer site by Amada Miyachi America field engineers who are able to provide the necessary level of...

Abrir o catálogo na página 5

5 AXIS GLOVEBOX SYSTEM • Position based laser firing in 5 axes for maintained spot overlap • Position based image acquisition of weld • High precision, quick change tooling • Integrated laser, motion and environmental controls This system enables the welding of complex paths that require coordinated firing of the laser with simultaneous motion in both linear and rotary axes, within a controlled environment. The in-house developed, position based firing algorithm for up to 5 axes of motion provides consistent weld spot overlap and ensures quality and reliability of each hermetic weld....

Abrir o catálogo na página 6

Maximizing laser on-time provides an efficient route to volume manufacturing. Our range of high volume workstation configurations offers a number of load/unload and simultaneous processing options that can be selected to best fit the specific application requirements. • Operator friendly loading • Quick change tooling • Simultaneous processing • Rotary tables, slides or draws • Multi station processing HIGH VOLUME LASER WORKSTATIONS

Abrir o catálogo na página 7

DUAL WAVELENGTH WELDING Both a 1064 and a 532nm pulsed Nd:YAG laser are combined into a 4 axis system for welding internal aluminum and copper terminal connections as well as external laser welding requirements. The combination of the two wavelengths enables reliable penetration welding of copper, while the high peak powers of the 1064nm laser enables high quality welding of aluminum with a spot size diameter up to 0.03 inches (0.75mm). The system provides all the flexibility of motion and tooling to accommodate the various joint configurations and tooling paths of 6 different welding...

Abrir o catálogo na página 8

Addressing the need for in-line manufacturing cells, our range of in-line systems for laser marking, cutting, welding and bonding are designed for conveyer feed with gantry mounted equipment. Motion is coordinated with part feed with SMEMA interfacing. A vision system can be implemented for either part alignment in both translation and rotation along with part orientation verification or laser mark check. • In-line sytems for marking, cutting, welding and bonding with SMEMA interfacing • Gantry mounted equipment and motion • Vision corrected motion for translation or rotation • Part...

Abrir o catálogo na página 9

LASER MARKING SYSTEMS Miyachi Unitek's standard Laser Marking Systems can be configured with any marker technology: help you select the appropriate laser marker and optics for your process! • Manual or semi-automated part marking • Rotary motion available for circumferential • Custom Muring available • Anti tie-down start controls and interlocking guard for fail-safe operation • Optional programmable focus compensates for differing part heights LASER SAFE VIEWING WINDOW OPTIONAL WORI- SUPPORT BASE SWIVEL CASTERS LEVEL JACKS

Abrir o catálogo na página 10

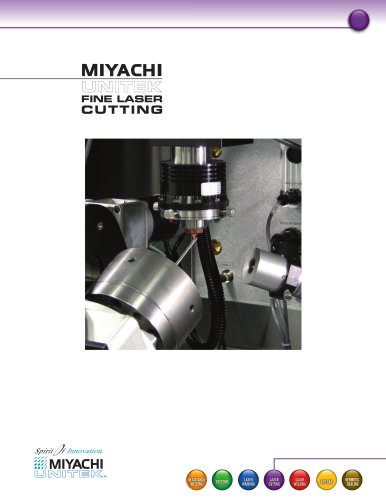

• High cut quality and dimensional accuracy • Wide range of materials including stainless steels, titanium, platinum iridium • Cut widths down to 20 microns • Up to 5 axes of coordinated motion • Proprietary position based firing laser control • Flexible laser source LASER CUTTING SYSTEMS Amada Miyachi America offers fine cutting systems with precision multi-axis motion and sophisticated software control features. Our proprietary position-based firing laser control algorithm enables precise pulsing overlap to be maintained during multiple linear and rotary axis coordinated motion. The laser...

Abrir o catálogo na página 11

DELTA SERIES LASER SYSTEMS Our range of standard laser processing platforms is specifically designed to maximize usable space for flexible configuration. • Gantry mounted focus heads • Standard enclosure widths from 20 to 53 inches • Manual or pneumatic doors • Up to 5 axes of coordinated motion • Linear motion envelope up to 24 x 24 inches • Clear and intutive control software • Power monitoring options SEAM SEALING SYSTEMS • Current control mode for sealing process • Programmable electrode force • Most complete line of power supplies in the industry • Extended electrode life with...

Abrir o catálogo na página 12Todos os catálogos e folhetos técnicos AMADA WELD TECH Inc.

-

TC-W100A

2 Páginas

-

MEA-100B

2 Páginas

-

MIB-300A/600A

2 Páginas

-

CD-A125A CD-A300A CD-A1000A

2 Páginas

-

Desktop Series ACF Laminating

2 Páginas

-

Hot Application Wire Stripping

4 Páginas

-

Rotary Dial Index Systems

2 Páginas

-

AMADA WELD TECH

24 Páginas

-

HF-2700A / HF-2500A

4 Páginas

-

CD-V Series

2 Páginas

-

MD-A10000A/ MD-B5000A

2 Páginas

-

ISQ Series

3 Páginas

-

IPB-5000A-MU

2 Páginas

-

MFP60 for aws3

2 Páginas

-

MFP25 FRO AWS3

2 Páginas

-

Series 320

2 Páginas

-

newhorizon

3 Páginas

-

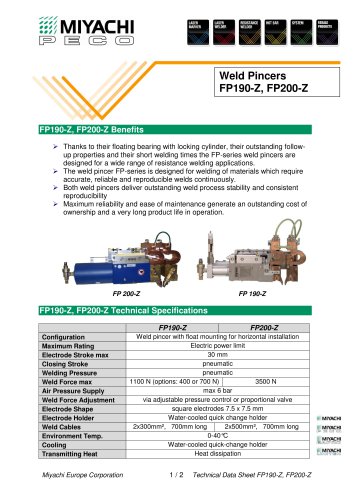

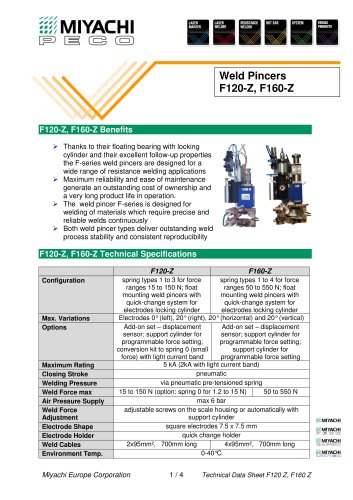

F120, F160, FD120

4 Páginas

-

KN-II Series

2 Páginas

-

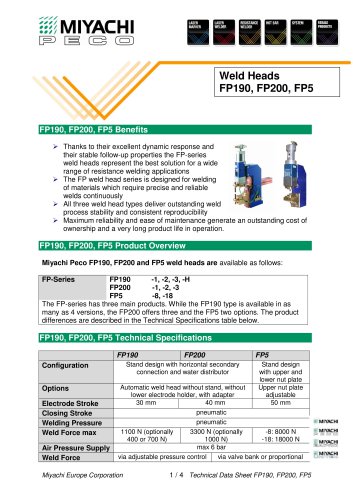

MH Weld Head Range

4 Páginas

-

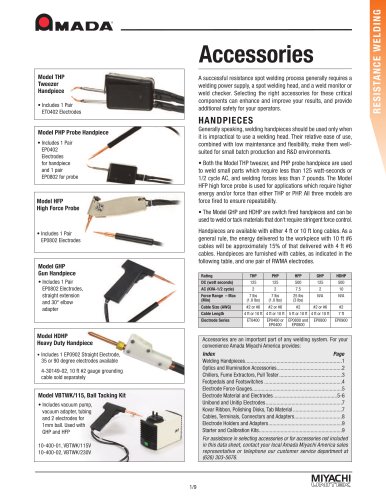

Accessries

9 Páginas

-

Laser Microfabrication

2 Páginas

-

ML-5120A

2 Páginas

-

LMWS Laser Marking Workstation

2 Páginas

-

Systems

16 Páginas

-

ML-5120

2 Páginas

-

DC29-UB29-UB29A

4 Páginas

-

LF Series Lasers

2 Páginas

-

SA2200 Dual Oven

2 Páginas

-

Laser Tube Cutting Systems

2 Páginas

-

Heat Staking

2 Páginas

-

Seam Laser Welder - 150W

2 Páginas

-

Fiber Laser Welders - 100W - 500W

2 Páginas

-

Micro Spot Laser Welder - LW5AM

2 Páginas

-

Pulsed Micro TIG Welder - MAWA-300A

2 Páginas

-

Micro TIG Accessories Brochure

4 Páginas

-

resistance welding Fundamentals

8 Páginas

-

Resistance Welding Accessories

9 Páginas

-

AX5000 Glovebox

2 Páginas

-

MX2000 Glovebox

2 Páginas

-

Alpha Series Glovebox Systems

2 Páginas

-

Benchmark AF8500 / AF 1250

2 Páginas

-

Pulsed-Heat Hot-Bar

10 Páginas

-

Benchmark SM8500

2 Páginas

-

vacuum bakeout oven

2 Páginas

-

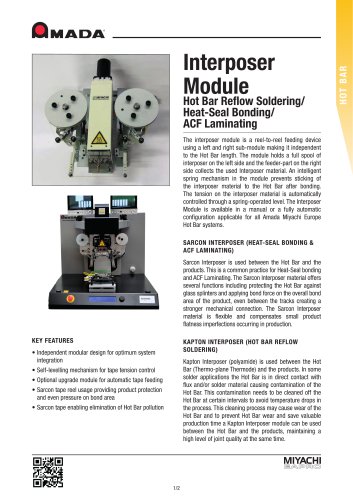

Interposer Module

2 Páginas

-

UV Laser Marking Systems

2 Páginas

-

CO2 Laser Marking Systems

2 Páginas

-

Sigma XY Fiber Laser Cutting System

2 Páginas

-

Linear DC Weld Controls - MDA-10000A

2 Páginas

-

Portable Weld Checker - MM-315A

8 Páginas

-

Fiber Laser Micro Welders

2 Páginas

-

Green Micro Spot Laser Welder - 5W

2 Páginas

-

Sigma Laser Tube Cutter

2 Páginas

-

Laser Marker Motion

2 Páginas

-

Macro Spot Laser Welders - 5 to 25W

2 Páginas

-

High Force Weld Heads - MH Series

4 Páginas

-

Nd:YVO4 'Green' Laser Marker - 5w

2 Páginas

-

Laser Welding Gloveboxes

2 Páginas

-

Thermocouple Welder - TCW

2 Páginas

-

Desktop Galvo Laser Welding Systems

2 Páginas

-

Laser Accessories

7 Páginas

-

Alpha Series

2 Páginas

-

MX-2000 Glovebox Technical

2 Páginas

-

AX-5000 Glovebox

2 Páginas

-

Benchmark Accessories

9 Páginas

-

Thin Line Weld Heads

8 Páginas

-

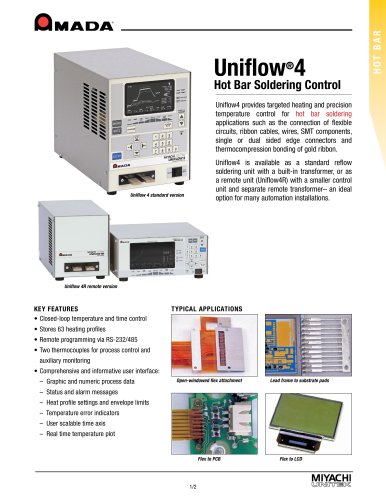

Uniflow 4

2 Páginas

-

Pulsar

2 Páginas

-

Laser Microfabrication System

2 Páginas

-

LMF Series Fiber Laser Markers

4 Páginas

-

LMC1 Laser Marker Motion

2 Páginas

-

LW300-600A

2 Páginas

-

LW50A-70-150A

2 Páginas

-

LW5-15-25A

2 Páginas

-

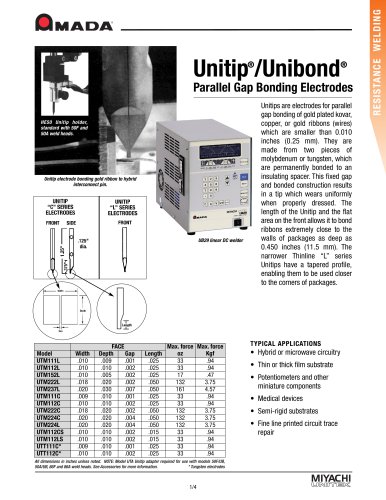

Unitip and Unibond Electrodes

4 Páginas

-

LF Series

2 Páginas

-

50 Series Weld Heads

4 Páginas

-

MH Series Weld Heads

4 Páginas

-

MG3

12 Páginas

-

MG3 Hot Bar Monitoring

3 Páginas

-

Hot Bar Process Calibration Tools

2 Páginas

-

Sarcon and Kapton Modules

2 Páginas

-

Thin-line

8 Páginas

-

IS series

2 Páginas

-

ISB-300 A

2 Páginas

-

Accessoires

9 Páginas

-

DC25, UB25

4 Páginas

-

Inverter Spot Weld Control - ISQ

4 Páginas

-

Laser Marking & Engraving Systems

2 Páginas

-

Fiber Laser Micro Welding Systems

2 Páginas

-

Nd:YV04 UV Laser Marker Systems

2 Páginas

-

Fine Laser Cutting Datasheet

4 Páginas

-

laser markers and marker systems

16 Páginas

-

Bonding Heads

2 Páginas

-

MG3 UNIQUE PROCESS MONITORING

12 Páginas

-

Premium Hot Bar Monitoring System

3 Páginas

-

Process Calibration Tools

2 Páginas

-

LaserCuttingSystems_Cut

4 Páginas

-

Pincer Weld Head - MFP-Z

3 Páginas

-

Color Digital Weld Monitor - MG3

4 Páginas

Catálogos arquivados

-

Fiber Laser Cutting System - 5 Axis

2 Páginas

-

Inverter Spot Weld Control - IS-120B

2 Páginas