Excertos do catálogo

Designed to improve the efficiency and throughput of a multi-step manufacturing process, rotary dial index systems assist in organizing steps and eliminating operator handling between steps. Amada Weld Tech specializes in building custom systems where either a single operator or robot is tasked with loading materials and unloading finished product. SYSTEM OPTIONS • Pneumatic or motorized indexer • Stage motion options: X, Y, Z, Rotary for part manipulation • Galvo scanhead option for quick point-to-point positioning • Controller options: AB PLC, DeltaTau® or MarkerMotion® • Connectivity to production networks: (ERP, MRP systems) • System process options: marking, engraving, welding, ablation • Adjustable height base for optimal operator ergonomics 3-position rotary dial index system TYPICAL APPLICATIONS Key features • Multiple positions tailored to the manufacturing process to improve throughput • Decrease cycle time in continuous production by performing steps in parallel Automotive part welding Medical component marking Aerospace component marking • Single operator or robot load/unload of product • Small footprint for lean manufacturing • Light tight laser processing area meets CDRH class 1 safety standards • Viewport and camera enables operator process monitoring • Optional real-time laser weld monitoring to inspect the weld and ensure quality, throughput and traceability

Abrir o catálogo na página 1

LASER PROCESS AREA LASER PROCESS AREA LASER PROCESS AREA Pre-process Check/Correction Laser Process Pre-process Check/Correction Laser Process Verification Unload Load Verification Unload OPERATOR WORK AREA Examples of multiple positions (left to right): 2-position, 3-position, 4-position Laser Process Pre-process Check/Correction Verification Unload OPERATOR WORK AREA OPERATOR WORK AREA Example: 2-position dial index system for laser marking Integration options • Part in place sensor to initiate cycle • Barcode imager • Custom user interface • Part-specific tooling • Machine vision...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos AMADA WELD TECH Inc.

-

TC-W100A

2 Páginas

-

MEA-100B

2 Páginas

-

MIB-300A/600A

2 Páginas

-

CD-A125A CD-A300A CD-A1000A

2 Páginas

-

Desktop Series ACF Laminating

2 Páginas

-

Hot Application Wire Stripping

4 Páginas

-

AMADA WELD TECH

24 Páginas

-

HF-2700A / HF-2500A

4 Páginas

-

CD-V Series

2 Páginas

-

MD-A10000A/ MD-B5000A

2 Páginas

-

ISQ Series

3 Páginas

-

IPB-5000A-MU

2 Páginas

-

MFP60 for aws3

2 Páginas

-

MFP25 FRO AWS3

2 Páginas

-

Series 320

2 Páginas

-

newhorizon

3 Páginas

-

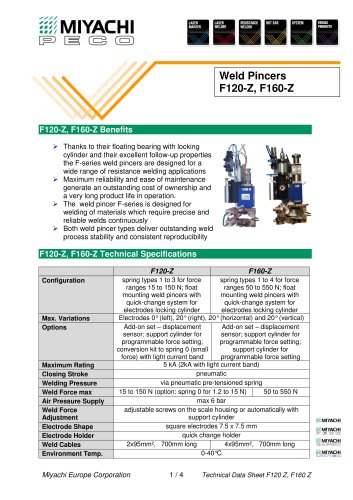

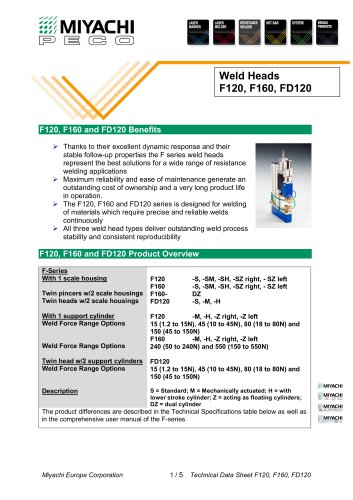

F120, F160, FD120

4 Páginas

-

KN-II Series

2 Páginas

-

MH Weld Head Range

4 Páginas

-

Accessries

9 Páginas

-

Laser Microfabrication

2 Páginas

-

ML-5120A

2 Páginas

-

LMWS Laser Marking Workstation

2 Páginas

-

Systems

16 Páginas

-

ML-5120

2 Páginas

-

DC29-UB29-UB29A

4 Páginas

-

LF Series Lasers

2 Páginas

-

SA2200 Dual Oven

2 Páginas

-

Laser Tube Cutting Systems

2 Páginas

-

Heat Staking

2 Páginas

-

Seam Laser Welder - 150W

2 Páginas

-

Systems Datasheet

16 Páginas

-

Fiber Laser Welders - 100W - 500W

2 Páginas

-

Micro Spot Laser Welder - LW5AM

2 Páginas

-

Pulsed Micro TIG Welder - MAWA-300A

2 Páginas

-

Micro TIG Accessories Brochure

4 Páginas

-

resistance welding Fundamentals

8 Páginas

-

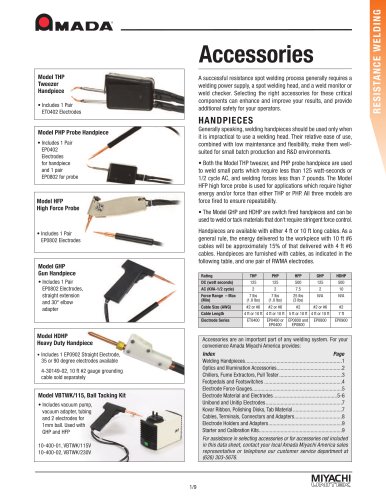

Resistance Welding Accessories

9 Páginas

-

AX5000 Glovebox

2 Páginas

-

MX2000 Glovebox

2 Páginas

-

Alpha Series Glovebox Systems

2 Páginas

-

Benchmark AF8500 / AF 1250

2 Páginas

-

Pulsed-Heat Hot-Bar

10 Páginas

-

Benchmark SM8500

2 Páginas

-

vacuum bakeout oven

2 Páginas

-

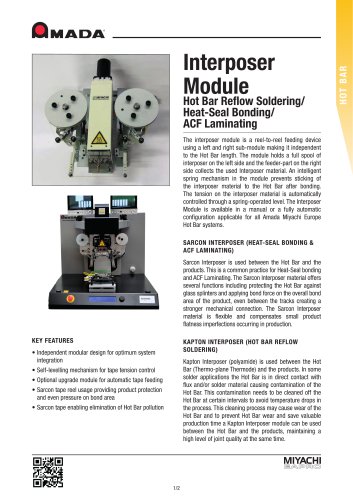

Interposer Module

2 Páginas

-

UV Laser Marking Systems

2 Páginas

-

CO2 Laser Marking Systems

2 Páginas

-

Sigma XY Fiber Laser Cutting System

2 Páginas

-

Linear DC Weld Controls - MDA-10000A

2 Páginas

-

Portable Weld Checker - MM-315A

8 Páginas

-

Fiber Laser Micro Welders

2 Páginas

-

Green Micro Spot Laser Welder - 5W

2 Páginas

-

Sigma Laser Tube Cutter

2 Páginas

-

Laser Marker Motion

2 Páginas

-

Macro Spot Laser Welders - 5 to 25W

2 Páginas

-

High Force Weld Heads - MH Series

4 Páginas

-

Nd:YVO4 'Green' Laser Marker - 5w

2 Páginas

-

Laser Welding Gloveboxes

2 Páginas

-

Thermocouple Welder - TCW

2 Páginas

-

Desktop Galvo Laser Welding Systems

2 Páginas

-

Laser Accessories

7 Páginas

-

Alpha Series

2 Páginas

-

MX-2000 Glovebox Technical

2 Páginas

-

AX-5000 Glovebox

2 Páginas

-

Benchmark Accessories

9 Páginas

-

Thin Line Weld Heads

8 Páginas

-

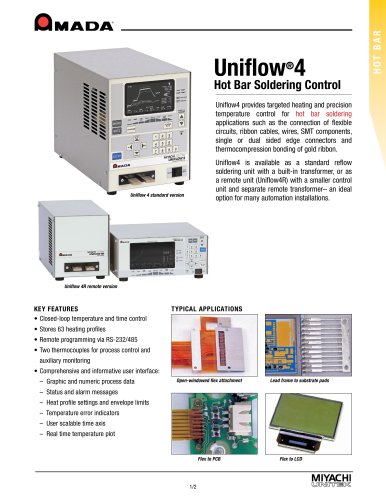

Uniflow 4

2 Páginas

-

Pulsar

2 Páginas

-

Laser Microfabrication System

2 Páginas

-

LMF Series Fiber Laser Markers

4 Páginas

-

LMC1 Laser Marker Motion

2 Páginas

-

LW300-600A

2 Páginas

-

LW50A-70-150A

2 Páginas

-

LW5-15-25A

2 Páginas

-

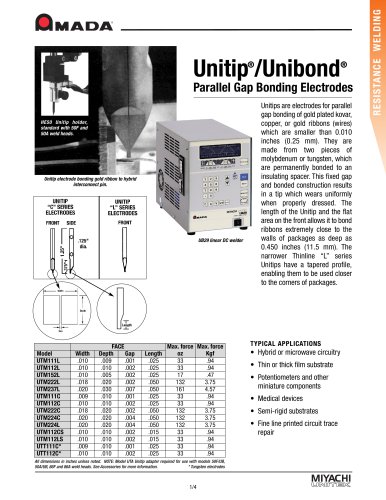

Unitip and Unibond Electrodes

4 Páginas

-

LF Series

2 Páginas

-

50 Series Weld Heads

4 Páginas

-

MH Series Weld Heads

4 Páginas

-

MG3

12 Páginas

-

MG3 Hot Bar Monitoring

3 Páginas

-

Hot Bar Process Calibration Tools

2 Páginas

-

Sarcon and Kapton Modules

2 Páginas

-

Thin-line

8 Páginas

-

IS series

2 Páginas

-

ISB-300 A

2 Páginas

-

Accessoires

9 Páginas

-

DC25, UB25

4 Páginas

-

Inverter Spot Weld Control - ISQ

4 Páginas

-

Laser Marking & Engraving Systems

2 Páginas

-

Fiber Laser Micro Welding Systems

2 Páginas

-

Nd:YV04 UV Laser Marker Systems

2 Páginas

-

Fine Laser Cutting Datasheet

4 Páginas

-

laser markers and marker systems

16 Páginas

-

Bonding Heads

2 Páginas

-

MG3 UNIQUE PROCESS MONITORING

12 Páginas

-

Premium Hot Bar Monitoring System

3 Páginas

-

Process Calibration Tools

2 Páginas

-

LaserCuttingSystems_Cut

4 Páginas

-

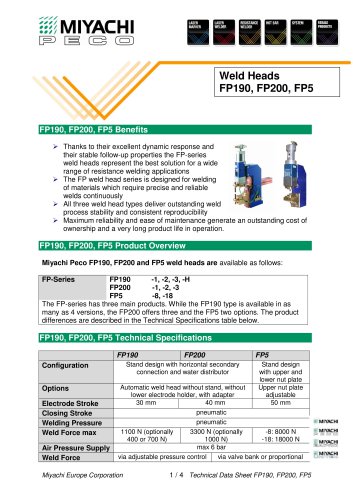

Pincer Weld Head - MFP-Z

3 Páginas

-

Color Digital Weld Monitor - MG3

4 Páginas

Catálogos arquivados

-

Fiber Laser Cutting System - 5 Axis

2 Páginas

-

Inverter Spot Weld Control - IS-120B

2 Páginas