Excertos do catálogo

• Spot sizes down to 10 microns • Penetration depth beyond 0.06 in (1.5 mm) in metals • Fine, high quality cutting of metals • Excellent power stability • Simple, intuitive user interface • Touchscreen The LF Series fiber lasers offer the precise control needed for small component welding and fine precision cutting of metals. A large touchscreen pendant enables clear visibility of process schedule parameters, and an intuitive interface enables quick and easy programming. TYPICAL APPLICATIONS • Micro welding – The laser is available in either single or multi-mode configuration. Precise control of the laser's pulse width and peak power enables fine micro welding processes. Penetrations up to 0.06 in (1.5 mm) in steels, titanium and nickel alloys are possible using continuous mode operation. • Precision cutting – LF Series fiber lasers can achieve focused spot sizes down to 10 microns providing the ultimate non contact cutting tool. High beam quality and high frequency enable high speed precision cutting of a range of metals. Medical spring attachment • Spot and seam welding – 10 segment pulse shaping enables best quality spot welding results. Ramp up and ramp down feature controls welding results at overlap. • Excellent power stability – Fine applications require high stability of the laser source for reliable processing. The LF Series offers excellent power and pulse to pulse stability with an internal air-to-water cooling mechanism which maintains stability irrespective of ambient air temperature. Medical component assembly • Touchscreen pendant – High definition 8 inch touchscreen pendant facilitates fast and intuitive laser programming. • Accessories – Full range of focus heads including inline, 90 degree with process viewing via a camera, and through the lens illumination options. Ultra compact heads are also available if space is a premium. Hypo tube cutting LASER WELDING

Abrir o catálogo na página 1

LASER WELDING TECHNICAL SPECIFICATIONS Optical Parameters Parameter Laser Specification Operation mode Maximum output power Dynamic range Beam quality Single mode and Multi-mode (50 µm core*) Positioning guide beam On axis, built in visible laser (Class 3R) Pulse modulation Square pulse Up slope, down slope 10 segment pulse shaping *Larger core diameters available upon request Integration Parameters Parameter Laser Specification BDO (beam delivery optic) QBH compatible (divergent beam) collimated beam also available for <500 W power External communication Operating temperature range...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos AMADA WELD TECH Inc.

-

TC-W100A

2 Páginas

-

MEA-100B

2 Páginas

-

MIB-300A/600A

2 Páginas

-

CD-A125A CD-A300A CD-A1000A

2 Páginas

-

Desktop Series ACF Laminating

2 Páginas

-

Hot Application Wire Stripping

4 Páginas

-

Rotary Dial Index Systems

2 Páginas

-

AMADA WELD TECH

24 Páginas

-

HF-2700A / HF-2500A

4 Páginas

-

CD-V Series

2 Páginas

-

MD-A10000A/ MD-B5000A

2 Páginas

-

ISQ Series

3 Páginas

-

IPB-5000A-MU

2 Páginas

-

MFP60 for aws3

2 Páginas

-

MFP25 FRO AWS3

2 Páginas

-

Series 320

2 Páginas

-

newhorizon

3 Páginas

-

F120, F160, FD120

4 Páginas

-

KN-II Series

2 Páginas

-

MH Weld Head Range

4 Páginas

-

Accessries

9 Páginas

-

Laser Microfabrication

2 Páginas

-

ML-5120A

2 Páginas

-

LMWS Laser Marking Workstation

2 Páginas

-

Systems

16 Páginas

-

ML-5120

2 Páginas

-

DC29-UB29-UB29A

4 Páginas

-

LF Series Lasers

2 Páginas

-

SA2200 Dual Oven

2 Páginas

-

Laser Tube Cutting Systems

2 Páginas

-

Heat Staking

2 Páginas

-

Seam Laser Welder - 150W

2 Páginas

-

Systems Datasheet

16 Páginas

-

Fiber Laser Welders - 100W - 500W

2 Páginas

-

Micro Spot Laser Welder - LW5AM

2 Páginas

-

Pulsed Micro TIG Welder - MAWA-300A

2 Páginas

-

Micro TIG Accessories Brochure

4 Páginas

-

resistance welding Fundamentals

8 Páginas

-

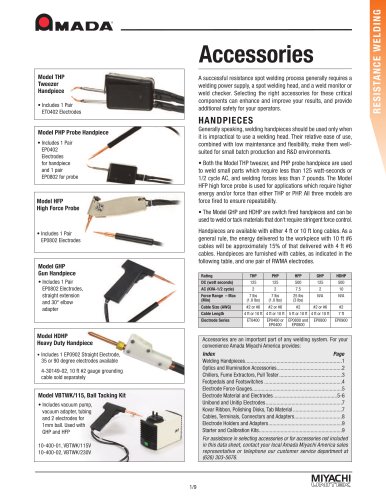

Resistance Welding Accessories

9 Páginas

-

AX5000 Glovebox

2 Páginas

-

MX2000 Glovebox

2 Páginas

-

Alpha Series Glovebox Systems

2 Páginas

-

Benchmark AF8500 / AF 1250

2 Páginas

-

Pulsed-Heat Hot-Bar

10 Páginas

-

Benchmark SM8500

2 Páginas

-

vacuum bakeout oven

2 Páginas

-

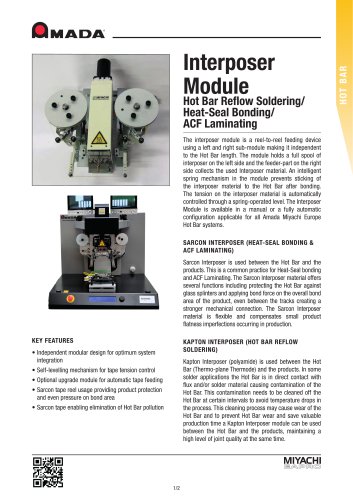

Interposer Module

2 Páginas

-

UV Laser Marking Systems

2 Páginas

-

CO2 Laser Marking Systems

2 Páginas

-

Sigma XY Fiber Laser Cutting System

2 Páginas

-

Linear DC Weld Controls - MDA-10000A

2 Páginas

-

Portable Weld Checker - MM-315A

8 Páginas

-

Fiber Laser Micro Welders

2 Páginas

-

Green Micro Spot Laser Welder - 5W

2 Páginas

-

Sigma Laser Tube Cutter

2 Páginas

-

Laser Marker Motion

2 Páginas

-

Macro Spot Laser Welders - 5 to 25W

2 Páginas

-

High Force Weld Heads - MH Series

4 Páginas

-

Nd:YVO4 'Green' Laser Marker - 5w

2 Páginas

-

Laser Welding Gloveboxes

2 Páginas

-

Thermocouple Welder - TCW

2 Páginas

-

Desktop Galvo Laser Welding Systems

2 Páginas

-

Laser Accessories

7 Páginas

-

Alpha Series

2 Páginas

-

MX-2000 Glovebox Technical

2 Páginas

-

AX-5000 Glovebox

2 Páginas

-

Benchmark Accessories

9 Páginas

-

Thin Line Weld Heads

8 Páginas

-

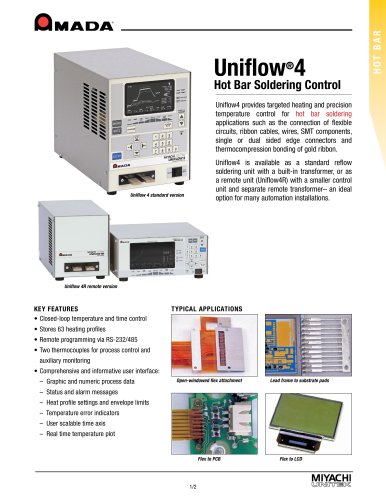

Uniflow 4

2 Páginas

-

Pulsar

2 Páginas

-

Laser Microfabrication System

2 Páginas

-

LMF Series Fiber Laser Markers

4 Páginas

-

LMC1 Laser Marker Motion

2 Páginas

-

LW300-600A

2 Páginas

-

LW50A-70-150A

2 Páginas

-

LW5-15-25A

2 Páginas

-

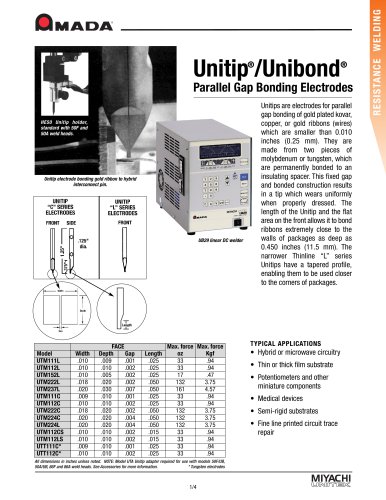

Unitip and Unibond Electrodes

4 Páginas

-

50 Series Weld Heads

4 Páginas

-

MH Series Weld Heads

4 Páginas

-

MG3

12 Páginas

-

MG3 Hot Bar Monitoring

3 Páginas

-

Hot Bar Process Calibration Tools

2 Páginas

-

Sarcon and Kapton Modules

2 Páginas

-

Thin-line

8 Páginas

-

IS series

2 Páginas

-

ISB-300 A

2 Páginas

-

Accessoires

9 Páginas

-

DC25, UB25

4 Páginas

-

Inverter Spot Weld Control - ISQ

4 Páginas

-

Laser Marking & Engraving Systems

2 Páginas

-

Fiber Laser Micro Welding Systems

2 Páginas

-

Nd:YV04 UV Laser Marker Systems

2 Páginas

-

Fine Laser Cutting Datasheet

4 Páginas

-

laser markers and marker systems

16 Páginas

-

Bonding Heads

2 Páginas

-

MG3 UNIQUE PROCESS MONITORING

12 Páginas

-

Premium Hot Bar Monitoring System

3 Páginas

-

Process Calibration Tools

2 Páginas

-

LaserCuttingSystems_Cut

4 Páginas

-

Pincer Weld Head - MFP-Z

3 Páginas

-

Color Digital Weld Monitor - MG3

4 Páginas

Catálogos arquivados

-

Fiber Laser Cutting System - 5 Axis

2 Páginas

-

Inverter Spot Weld Control - IS-120B

2 Páginas