Excertos do catálogo

AF8500/AF1250 Autoflow Lid Placement, Tack and Seam Sealing Systems The AF series automated seam sealing systems provide users with the flexibility to meet the increasing demands of lid placement and seam sealing either as a stand-alone unit or as part of a fully integrated glovebox or automated manufacturing line. The computercontrolled precision tacking and seam-sealing mechanism is combined with a high frequency inverter power supply, and an optional high resolution vision system to provide a robust and repeatable process. KEY FEATURES • Programmable electrode force and weld current using a Windows®-based proprietary software • Closed-loop high frequency inverter welding power supply features low sealing temperatures and power feedback, increasing yields and productivity • Current control mode optimized for superior seam sealing results • Position-based weld pulses ensure consistent spot spacing, optimized spot density at corners, reduced leaks, and elimination of acceleration/deceleration problems • Auto-Trak™ software indexes electrodes ensuring extended electrode life and more even wear • Electrode roll-back feature assists in electrode release from lightweight parts • Automated lid alignment and placement option holds lid in place during tacking, preventing misalignment; easy-to-program vision software • Automated magazine loader option loads from either top or bottom for a fully or semi-automated part handling system TYPICAL APPLICATIONS HERM ETIC SEALING

Abrir o catálogo na página 1

HERM ETIC SEALING WIDE RANGE OF PART PROCESSING CAPABILITIES • Operates as tacker only, sealer only, or combined tacker-sealer • Four-pass welding feature starts weld from center and welds to the part corner – best for large parts sealing • Set different energy levels for each axis welded for higher yields on rectangular parts • Single or double side tack options • Real time monitoring of weld inhibit inputs such as moisture, oxygen, and helium levels • Unlimited weld schedule storage • Lid hold-down feature assists tacking process • Chain or link multiple schedules together Model AF1250-ST...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos AMADA WELD TECH Inc.

-

TC-W100A

2 Páginas

-

MEA-100B

2 Páginas

-

MIB-300A/600A

2 Páginas

-

CD-A125A CD-A300A CD-A1000A

2 Páginas

-

Desktop Series ACF Laminating

2 Páginas

-

Hot Application Wire Stripping

4 Páginas

-

Rotary Dial Index Systems

2 Páginas

-

AMADA WELD TECH

24 Páginas

-

HF-2700A / HF-2500A

4 Páginas

-

CD-V Series

2 Páginas

-

MD-A10000A/ MD-B5000A

2 Páginas

-

ISQ Series

3 Páginas

-

IPB-5000A-MU

2 Páginas

-

MFP60 for aws3

2 Páginas

-

MFP25 FRO AWS3

2 Páginas

-

Series 320

2 Páginas

-

newhorizon

3 Páginas

-

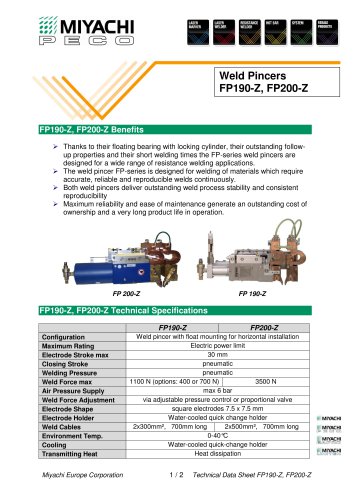

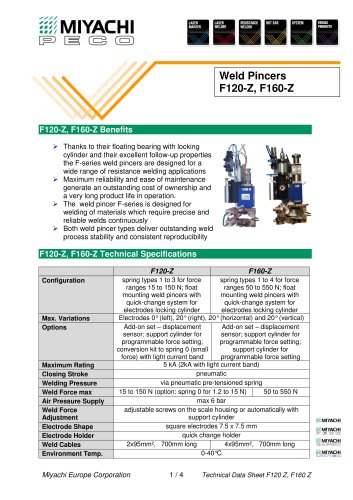

F120, F160, FD120

4 Páginas

-

KN-II Series

2 Páginas

-

MH Weld Head Range

4 Páginas

-

Accessries

9 Páginas

-

Laser Microfabrication

2 Páginas

-

ML-5120A

2 Páginas

-

LMWS Laser Marking Workstation

2 Páginas

-

Systems

16 Páginas

-

ML-5120

2 Páginas

-

DC29-UB29-UB29A

4 Páginas

-

LF Series Lasers

2 Páginas

-

SA2200 Dual Oven

2 Páginas

-

Laser Tube Cutting Systems

2 Páginas

-

Heat Staking

2 Páginas

-

Seam Laser Welder - 150W

2 Páginas

-

Systems Datasheet

16 Páginas

-

Fiber Laser Welders - 100W - 500W

2 Páginas

-

Micro Spot Laser Welder - LW5AM

2 Páginas

-

Pulsed Micro TIG Welder - MAWA-300A

2 Páginas

-

Micro TIG Accessories Brochure

4 Páginas

-

resistance welding Fundamentals

8 Páginas

-

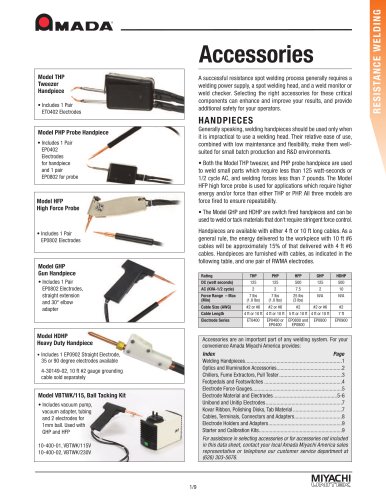

Resistance Welding Accessories

9 Páginas

-

AX5000 Glovebox

2 Páginas

-

MX2000 Glovebox

2 Páginas

-

Alpha Series Glovebox Systems

2 Páginas

-

Pulsed-Heat Hot-Bar

10 Páginas

-

Benchmark SM8500

2 Páginas

-

vacuum bakeout oven

2 Páginas

-

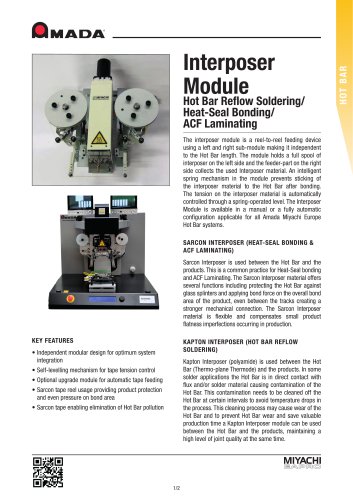

Interposer Module

2 Páginas

-

UV Laser Marking Systems

2 Páginas

-

CO2 Laser Marking Systems

2 Páginas

-

Sigma XY Fiber Laser Cutting System

2 Páginas

-

Linear DC Weld Controls - MDA-10000A

2 Páginas

-

Portable Weld Checker - MM-315A

8 Páginas

-

Fiber Laser Micro Welders

2 Páginas

-

Green Micro Spot Laser Welder - 5W

2 Páginas

-

Sigma Laser Tube Cutter

2 Páginas

-

Laser Marker Motion

2 Páginas

-

Macro Spot Laser Welders - 5 to 25W

2 Páginas

-

High Force Weld Heads - MH Series

4 Páginas

-

Nd:YVO4 'Green' Laser Marker - 5w

2 Páginas

-

Laser Welding Gloveboxes

2 Páginas

-

Thermocouple Welder - TCW

2 Páginas

-

Desktop Galvo Laser Welding Systems

2 Páginas

-

Laser Accessories

7 Páginas

-

Alpha Series

2 Páginas

-

MX-2000 Glovebox Technical

2 Páginas

-

AX-5000 Glovebox

2 Páginas

-

Benchmark Accessories

9 Páginas

-

Thin Line Weld Heads

8 Páginas

-

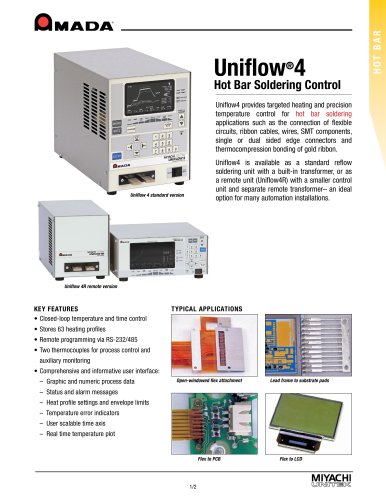

Uniflow 4

2 Páginas

-

Pulsar

2 Páginas

-

Laser Microfabrication System

2 Páginas

-

LMF Series Fiber Laser Markers

4 Páginas

-

LMC1 Laser Marker Motion

2 Páginas

-

LW300-600A

2 Páginas

-

LW50A-70-150A

2 Páginas

-

LW5-15-25A

2 Páginas

-

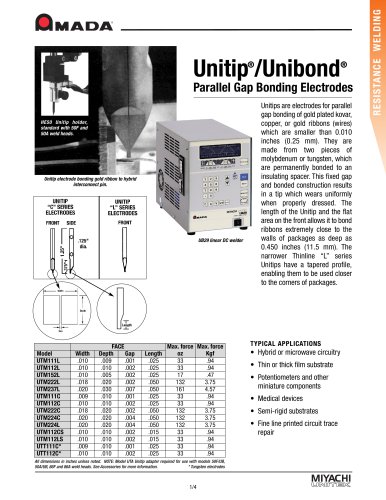

Unitip and Unibond Electrodes

4 Páginas

-

LF Series

2 Páginas

-

50 Series Weld Heads

4 Páginas

-

MH Series Weld Heads

4 Páginas

-

MG3

12 Páginas

-

MG3 Hot Bar Monitoring

3 Páginas

-

Hot Bar Process Calibration Tools

2 Páginas

-

Sarcon and Kapton Modules

2 Páginas

-

Thin-line

8 Páginas

-

IS series

2 Páginas

-

ISB-300 A

2 Páginas

-

Accessoires

9 Páginas

-

DC25, UB25

4 Páginas

-

Inverter Spot Weld Control - ISQ

4 Páginas

-

Laser Marking & Engraving Systems

2 Páginas

-

Fiber Laser Micro Welding Systems

2 Páginas

-

Nd:YV04 UV Laser Marker Systems

2 Páginas

-

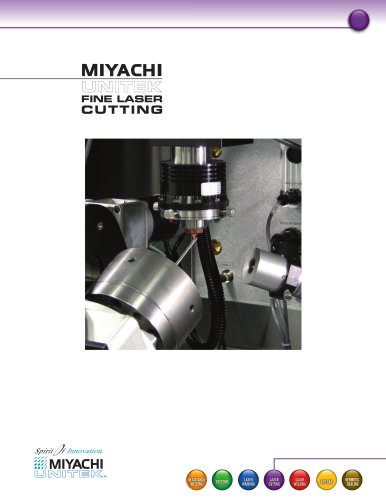

Fine Laser Cutting Datasheet

4 Páginas

-

laser markers and marker systems

16 Páginas

-

Bonding Heads

2 Páginas

-

MG3 UNIQUE PROCESS MONITORING

12 Páginas

-

Premium Hot Bar Monitoring System

3 Páginas

-

Process Calibration Tools

2 Páginas

-

LaserCuttingSystems_Cut

4 Páginas

-

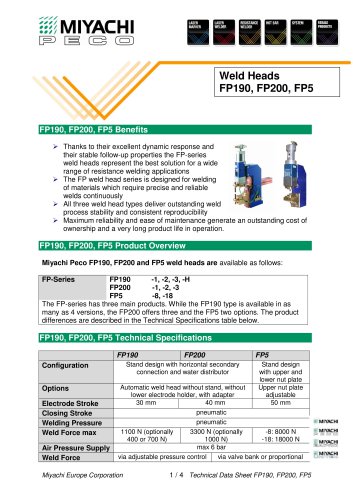

Pincer Weld Head - MFP-Z

3 Páginas

-

Color Digital Weld Monitor - MG3

4 Páginas

Catálogos arquivados

-

Fiber Laser Cutting System - 5 Axis

2 Páginas

-

Inverter Spot Weld Control - IS-120B

2 Páginas