Website:

Zumex Food Engineering

Website:

Zumex Food Engineering

Catalog excerpts

PROCESS SOLUTIONS | FRUIT TREATMENT LINE SELECTION, WASHING AND LOADING HOPPER Z450 Fruit treatment line for our Z450 citrus fruit extractor for 1 ton/h of previously calibrated fruit. It is comprised of selection, brush washer and storage hopper connected by conveyor elements and made of AISI 304 stainless steel. TECHNICAL CHARACTERISTICS For treating 1 ton/h of previously calibrated fruit . CONTROL PANEL BRUSH WASHER FRUIT STORAGE It has a programmable IP65 control panel with speed regulator to control motors by means of frequency converter, luminous and acoustic emergency signals, with two independent emergency pushbuttons. Brush washer with three independent areas: washing, rinsing and drying. Storage Hopper to regulate fruit before juice extraction, with adjustable unloading belt and speed variation. Comprised of 15 rows of nylon brushes with push system, 4 shower lines (two for detergent and 2 for rinsing), including detergent dispensing pumps and a drying area with 2 fans. Fruit level control via photocell. The roller rotation speed (brushing function) is controlled by means of speed converter. FRUIT SELECTION Aluminium roller conveyor for fruit selection and removal of damaged fruit. Comprised of area for tipping boxes and selection area with speed adjustment to adjust selection capacity. FOOD ENGINEERING

Open the catalog to page 1All Zumex Food Engineering catalogs and technical brochures

-

CIP SYSTEM

1 Pages

-

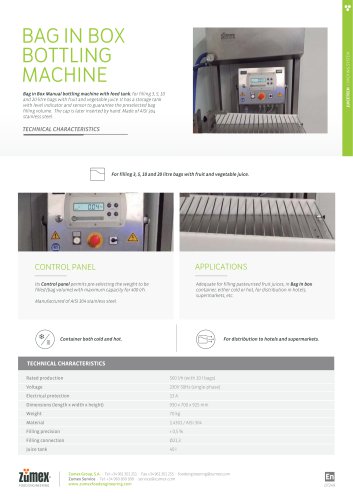

BAG IN BOX BOTTLING MACHINE

1 Pages

-

SCREW PRESS ZSP5

1 Pages

-

PADDLE FINISHERZPF

1 Pages

-

OIL EXTRACTOR ET6

1 Pages

-

PASTEURIZADOR FLASHZF1000

2 Pages

-

MASTERY

2 Pages

-

DEPULPER ZPD500

1 Pages

-

ELEVATOR CRUSHERZRC500

1 Pages

-

MULTIFRUIT ZMF400

1 Pages

-

CITRUS JUICE EXTRACTOR PJE

2 Pages

-

CITRUSZ450

1 Pages

-

ZPD500 / DEPULPER

1 Pages

-

Mastery Commercial Juicer

2 Pages

-

JuiceTech

7 Pages